Humic acid type porous adsorption material and preparation method and application thereof

A technology of porous adsorption material and potassium humate, applied in the field of humic acid-type porous adsorption material and preparation thereof, can solve the problems of low efficiency of heavy metal ions and organic pollutants, limited specific surface area, secondary pollution, etc., and achieves enhanced adsorption or The effect of complexation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

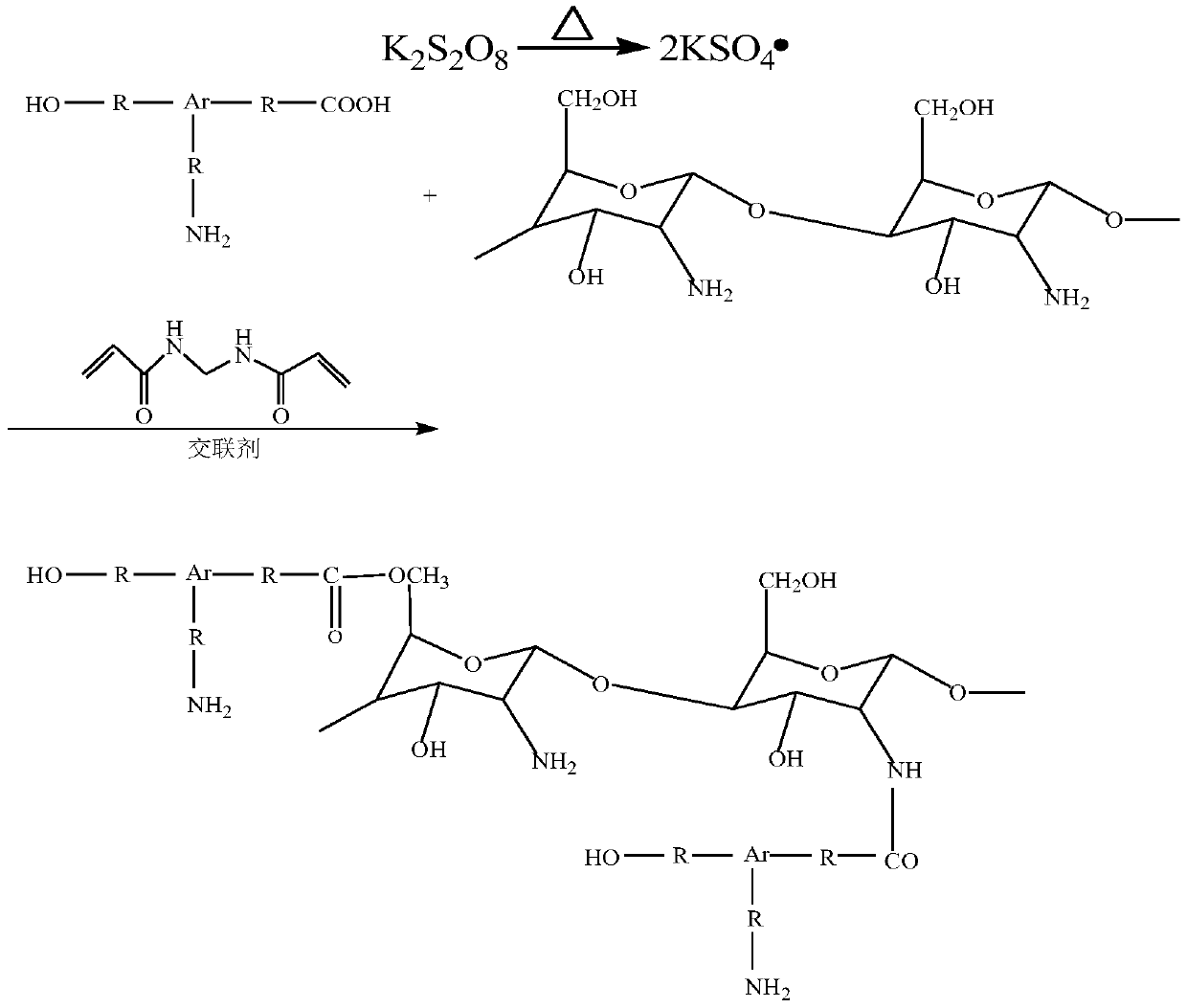

Method used

Image

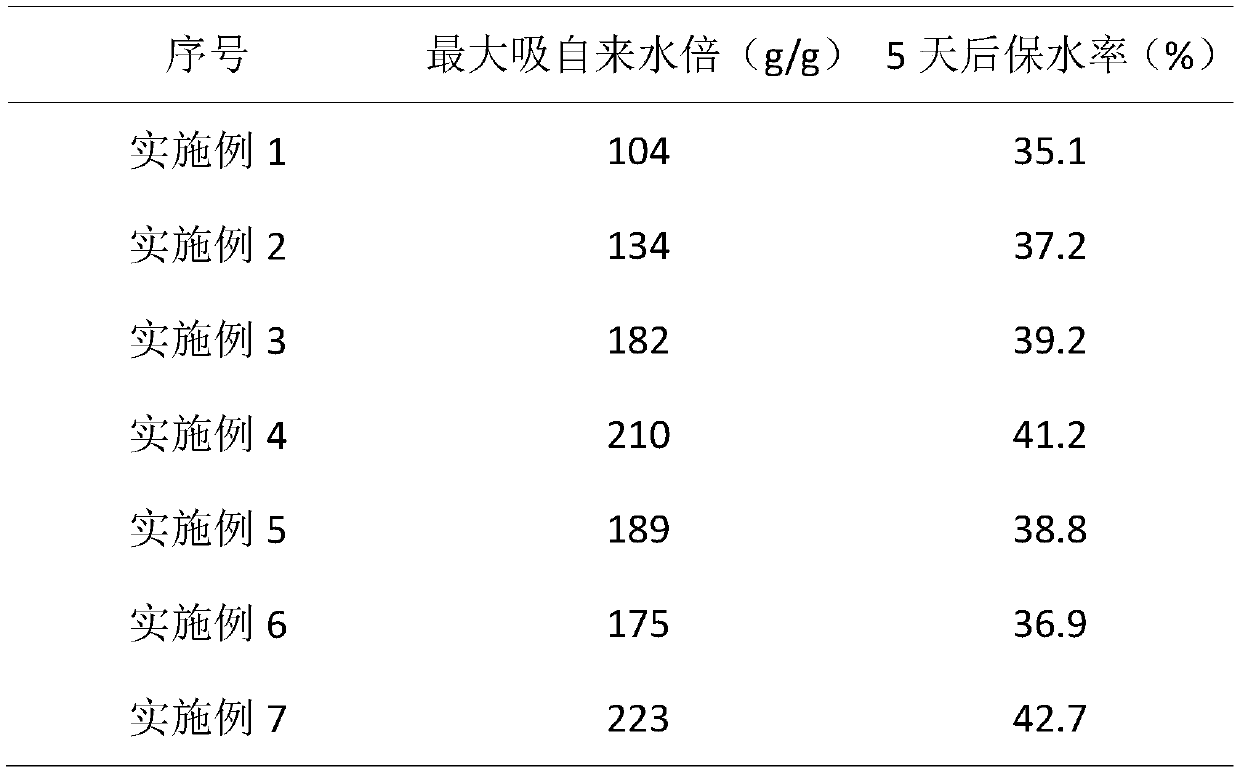

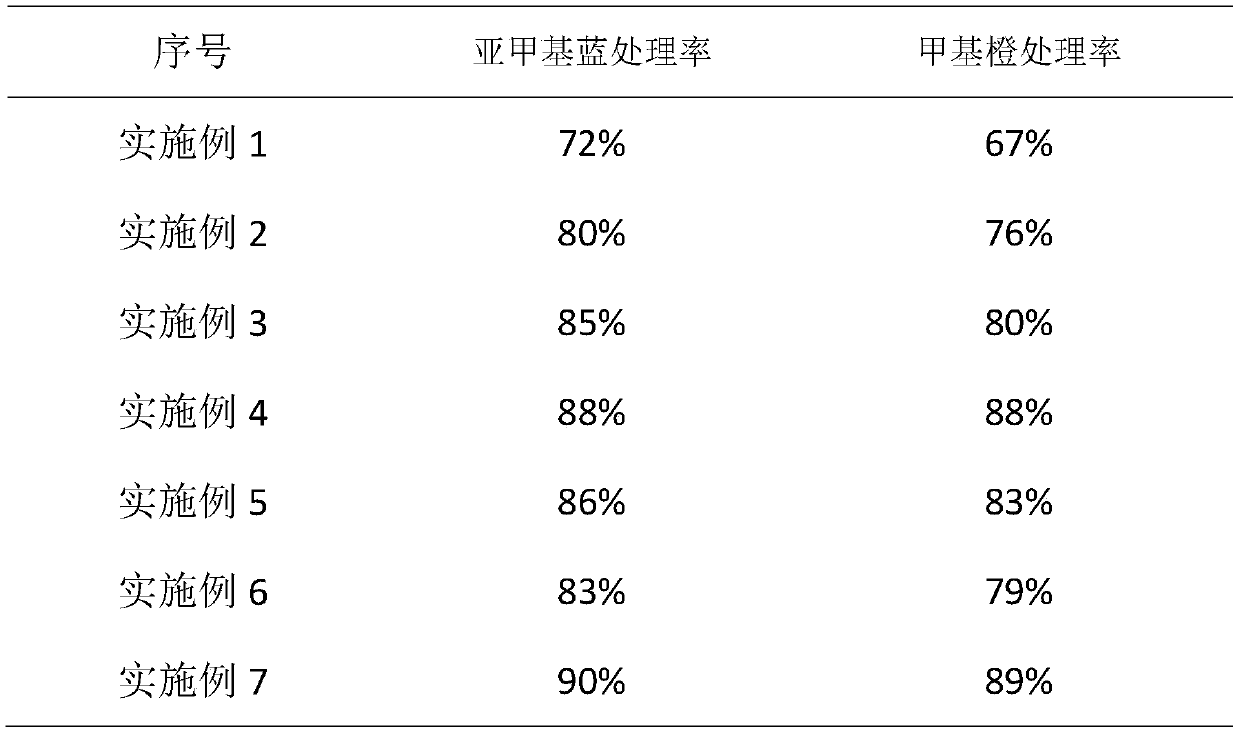

Examples

Embodiment 1

[0031] Weigh 1 part of potassium humate and 0.5 part of chitosan into a three-neck flask, add 40 parts of distilled water, turn on the stirring device to stir at a rate of 120 r / min, and at the same time raise the temperature from room temperature to 55 at a rate of 2 °C / min. ℃; add dropwise a solution prepared by dissolving 0.005 parts of potassium persulfate and 0.005 parts of N,N-methylenebisacrylamide in 20 parts of distilled water to the above reaction system, and control the dropping time for 35 minutes; Raise the temperature to 75°C at a heating rate of 1 / min, keep it for 5 minutes, add 2 parts of polyethylene glycol, and then stir at a speed of 100r / min, stop the reaction when the system becomes viscous and gel-like, and it is difficult to stir, and take out the product Drying is carried out at 75° C. to obtain a humic acid type porous adsorption material.

Embodiment 2

[0033] Weigh 2 parts of potassium humate and 0.5 parts of cellulose into a three-neck flask, add 50 parts of deionized water, turn on the stirring device to stir at a rate of 160r / min, and at the same time raise the temperature from room temperature at a rate of 4°C / min to 65°C; add dropwise a solution prepared by dissolving 0.16 parts of ammonium persulfate and 0.04 parts of N-methyldiethanolamine in 20 parts of distilled water to the above reaction system, and control the dropping time for 45 minutes; Raise the temperature to 80°C, keep it for 10 minutes, then add 3 parts of polyethylene glycol, and then stir at a speed of 120r / min, stop the reaction when the system becomes viscous and difficult to stir, take out the product and dry it at 80°C, A humic acid type porous adsorption material is obtained.

Embodiment 3

[0035] Weigh 3 parts of potassium humate and 1 part of cellulose into a three-necked flask, add 60 parts of deionized water, turn on the stirring device to stir at a rate of 130r / min, and at the same time raise the temperature from room temperature at a rate of 3°C / min to 60°C; add dropwise a solution prepared by dissolving 0.12 parts of ammonium persulfate and 0.03 parts of N-methyldiethanolamine in 20 parts of distilled water to the above reaction system, and control the dropping time for 40 minutes; then continue at a rate of 3°C / min Raise the temperature to 80°C, keep it for 8 minutes, add 4 parts of polyethylene glycol, and then stir at a rate of 110r / min, stop the reaction when the system becomes viscous and difficult to stir, take out the product and dry it at 80°C, A humic acid type porous adsorption material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com