Powder-needle nitrogen filling device and nitrogen filling method

A powder injection and nitrogen technology, applied in the direction of pressurization/gasification packaging, screwless plugs, etc., can solve the problems of complex design, inability to popularize and use, and the residual oxygen content cannot be effectively controlled, and achieves simple structure and debugging. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

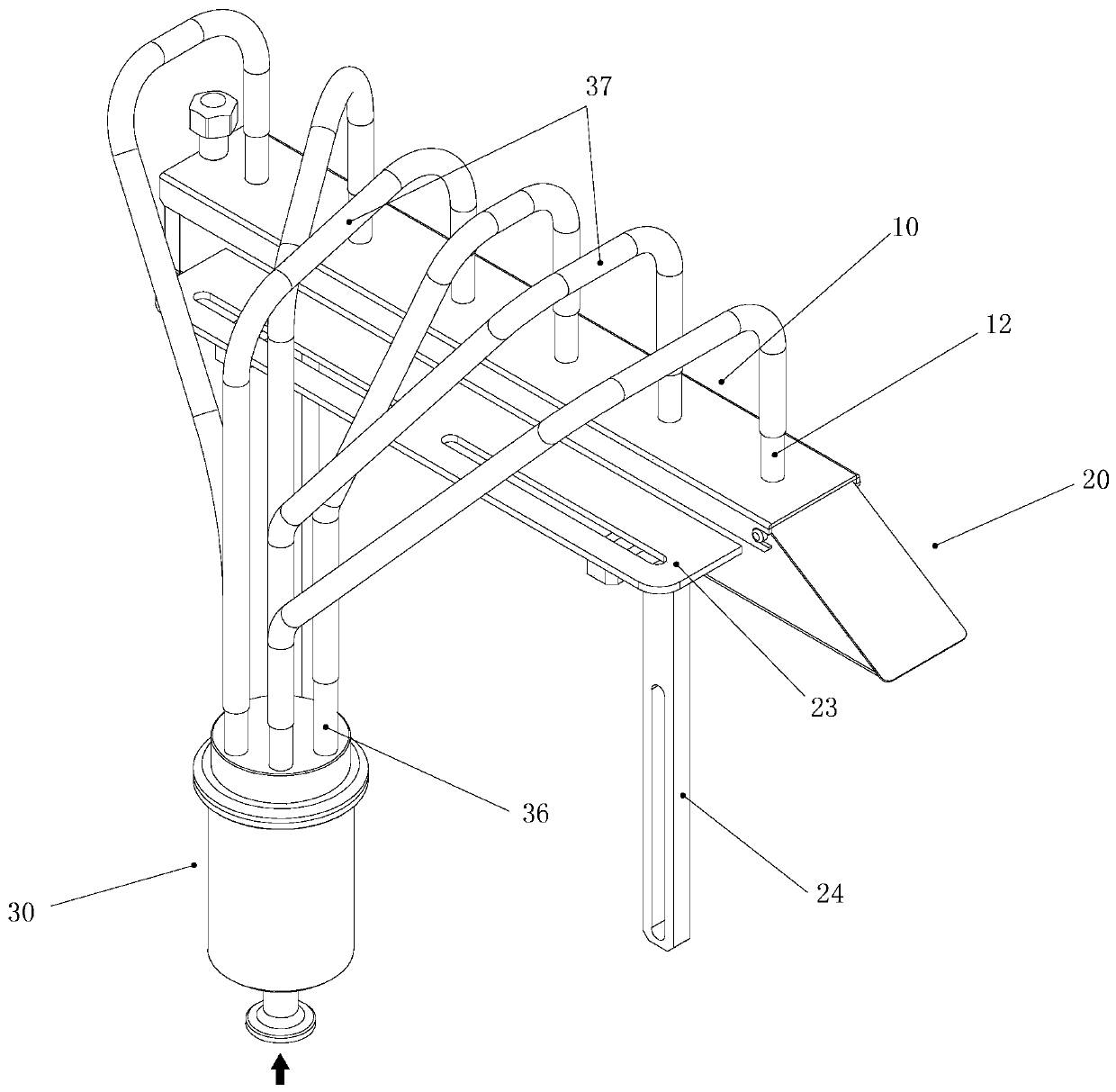

[0040] See figure 1 , a kind of powder needle nitrogen charging device designed in the preferred embodiment of the present invention, it mainly includes: buffer tank 30 and diversion gas charging mechanism, this device is used together with conveying belt 5 and rubber plug wheel mechanism 6, completes the medicine bottle Nitrogen filling, each component and connection relationship will be described in detail below.

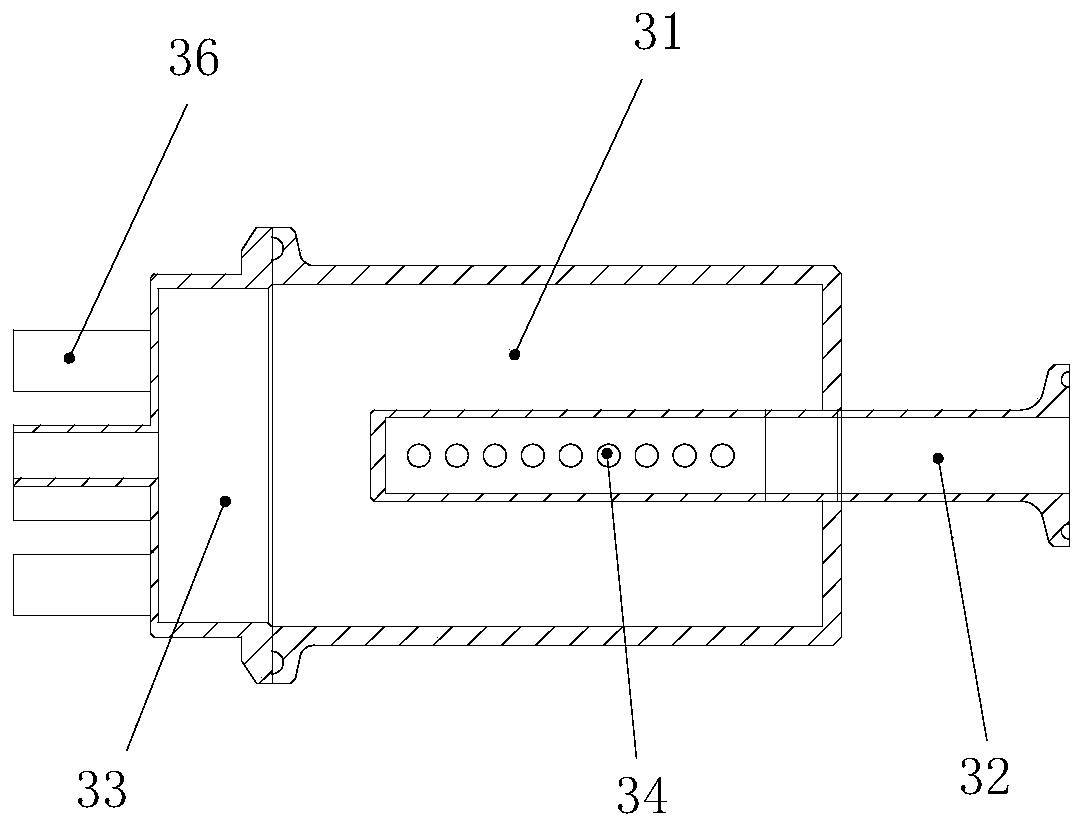

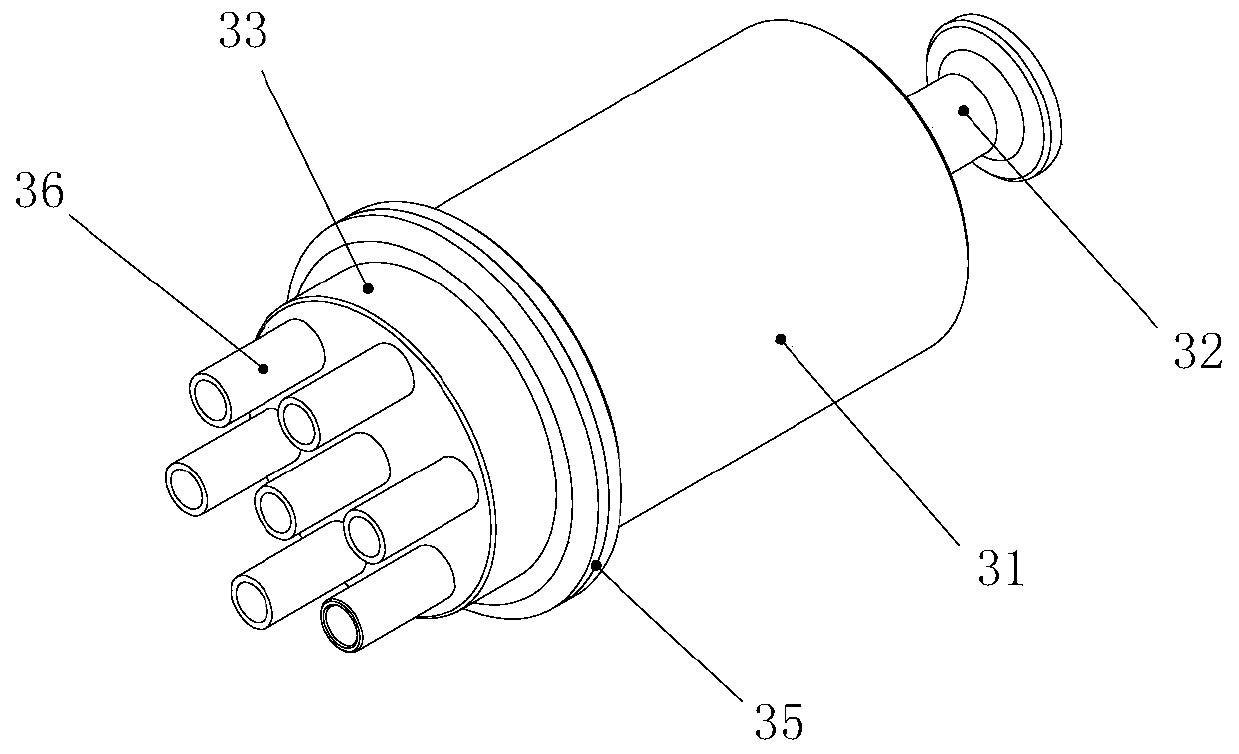

[0041] See Figure 1 to Figure 3 , The buffer tank 30 includes: a cylindrical tank body 31 , an air source mouthpiece 32 protruding and inserted in the middle of the bottom end of the tank body 31 , and a distribution seat 33 sealed and installed on the top end of the tank body 31 . The end of the gas source interface tube 32 is a quick-loading chuck at the gas source inlet, which is directly connected to the pipe mouth clamp of the nitrogen source. The other end of the gas source interface tube 32 inserted into the tank body 31 adopts a sealing design, so it mus...

Embodiment 2

[0062] A method for filling nitrogen into powder needles according to the second preferred embodiment of the present invention, specifically comprising:

[0063] First use the nitrogen filling device described in the preferred embodiment 1 to form a nitrogen filling channel that continuously sprays nitrogen gas. The length of the nitrogen filling channel is not less than 350mm, and the height of the nitrogen filling channel from the bottle mouth is 3mm. The nitrogen source pressure of the nitrogen filling device Not less than 8psi, the powder-filled medicine bottle passes directly under the nitrogen filling channel at a speed of 224 bottles per minute on the conveyor belt, and the bottle is filled with nitrogen gas; after passing through the nitrogen filling channel, the rubber plug wheel mechanism is used to The bottle mouth is pressed into the rubber stopper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bottle mouth diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com