Polyepoxy water-borne epoxy latex for portland cement slurry and preparation method thereof

A water-based epoxy emulsion and multi-epoxy technology, applied in the field of Portland cement slurry materials, can solve the problems of demulsification, affecting the stability of Portland cement slurry, poor compatibility of Portland cement slurry, etc. Improved compressive strength, beneficial stability, excellent emulsifier structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

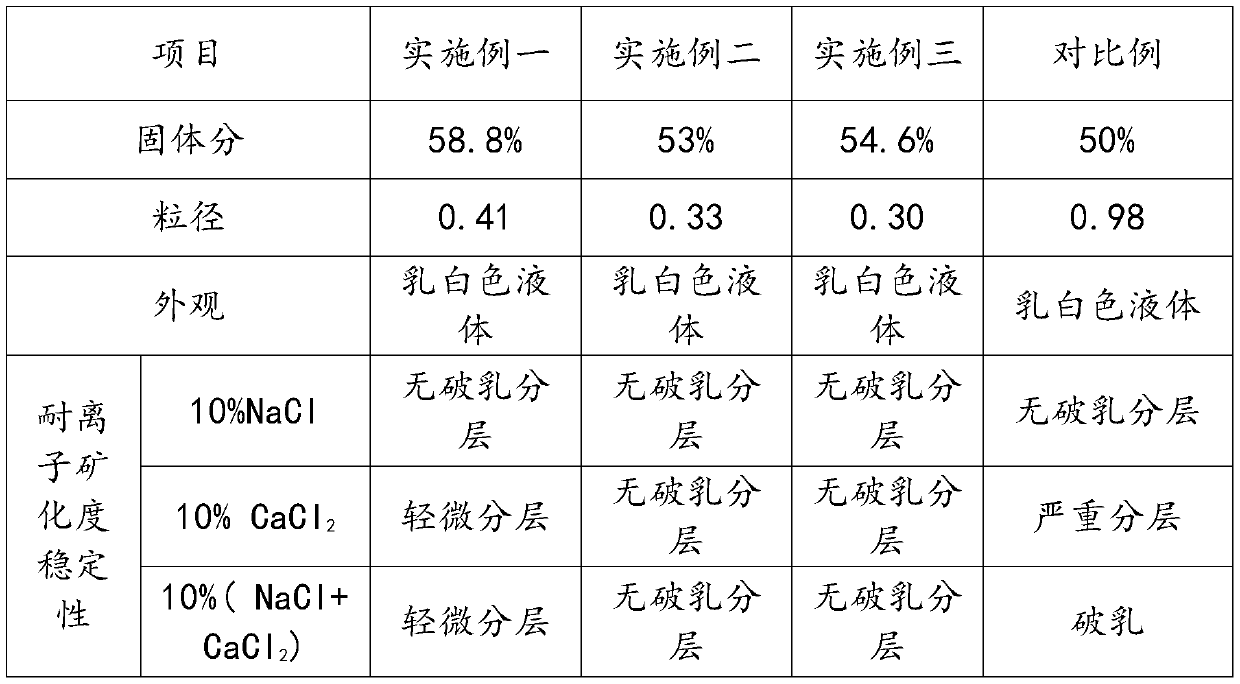

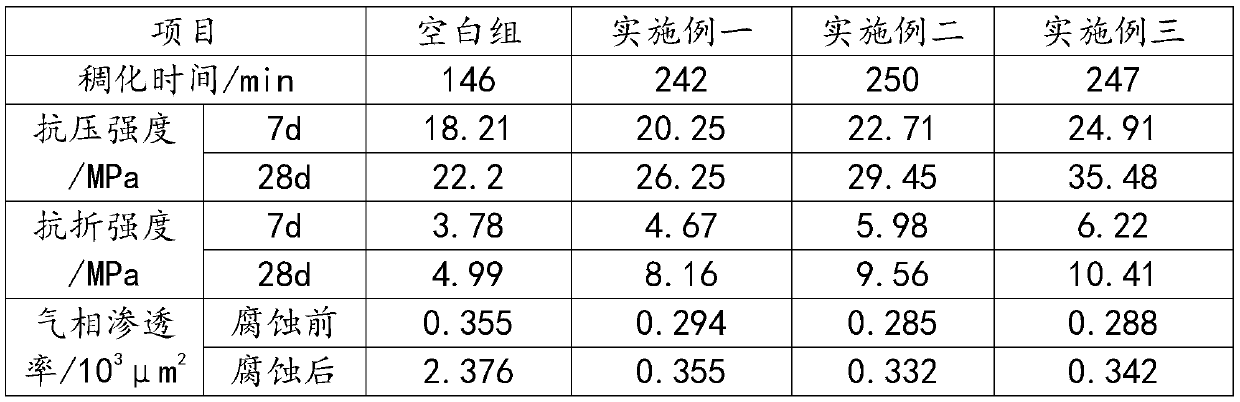

Examples

Embodiment 1

[0029] The Portland cement slurry of the present embodiment is made from the following raw materials in mass percent: 55% of E-51 epoxy resin, 5% of polyepoxy emulsifier, 40% of deionized water %, the polyepoxy-based emulsifier is made from the following raw materials in mass percent: E-51 epoxy resin 14%, polyethylene glycol (molecular weight is 5000) 60%, methyltetrahydrophthalic anhydride 10%, ethylene glycol Alcohol ether 16%.

[0030] The preparation method of the above-mentioned Portland cement slurry with many epoxy-based water-based epoxy emulsions may further comprise the steps:

[0031] 1) Under mechanical stirring, methyltetrahydrophthalic anhydride, ethylene glycol ether 16% and polyethylene glycol (molecular weight: 5000) were stirred and reacted at 150°C for 2 hours, and then E-51 epoxy resin was added under stirring, Continue to react at 150°C for 2 hours to prepare a multi-epoxy emulsifier;

[0032] 2) Heat E-51 epoxy resin, the polyepoxy-based emulsifier and...

Embodiment 2

[0034] The Portland cement slurry of the present embodiment is made from the following raw materials in mass percent: 41% of E-44 epoxy resin, 15% of polyepoxy emulsifier, and 10% of propylene glycol methyl ether for the Portland cement slurry of the present embodiment. %, deionized water 34%, and the polyepoxy emulsifier is made from the raw material of following mass percent: E-44 epoxy resin 15%, polyethylene glycol (molecular weight is 6000) 75%, methylhexahydro Phthalic anhydride 5%, propylene glycol methyl ether 5%.

[0035] The preparation method of the above-mentioned Portland cement slurry with many epoxy-based water-based epoxy emulsions may further comprise the steps:

[0036] 1) Under mechanical stirring, methyl hexahydrophthalic anhydride, propylene glycol methyl ether and polyethylene glycol (molecular weight: 6000) were stirred and reacted at 155°C for 3h, then continued to add E-44 epoxy resin under stirring, at 155°C Continue to react for 3h to make many epox...

Embodiment 3

[0039] The Portland cement slurry of the present embodiment is made from the following raw materials in mass percent: 49% of E-20 epoxy resin, 12% of polyepoxide emulsifier, and 9% of propylene glycol ether , deionized water 30%, and described polyepoxy emulsifier is made by the raw material of following mass percent: E-20 epoxy resin 28%, polyethylene glycol (molecular weight is 8000) 57%, phthalic anhydride 7%, propylene glycol ether 8%.

[0040] The preparation method of the above-mentioned Portland cement slurry with many epoxy-based water-based epoxy emulsions may further comprise the steps:

[0041] 1) Under mechanical stirring, stir phthalic anhydride, propylene glycol ethyl ether and polyethylene glycol (molecular weight: 8000) at 160°C for 4 hours, then continue to add E-20 epoxy resin under stirring, at 160°C Continue to react for 4h to make many epoxy-based emulsifiers;

[0042] 2) Heat E-20 epoxy resin, the polyepoxy-based emulsifier and propylene glycol ethyl et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com