Preparation method for hydroxyl acrylic resin

A hydroxyacrylic acid and acrylate technology, applied in adhesive types, coatings, hydrocarbon copolymer adhesives, etc., can solve the problems of slow drying speed, high cost, short activation period, etc., to improve quality, Increased compatibility, smooth and even response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

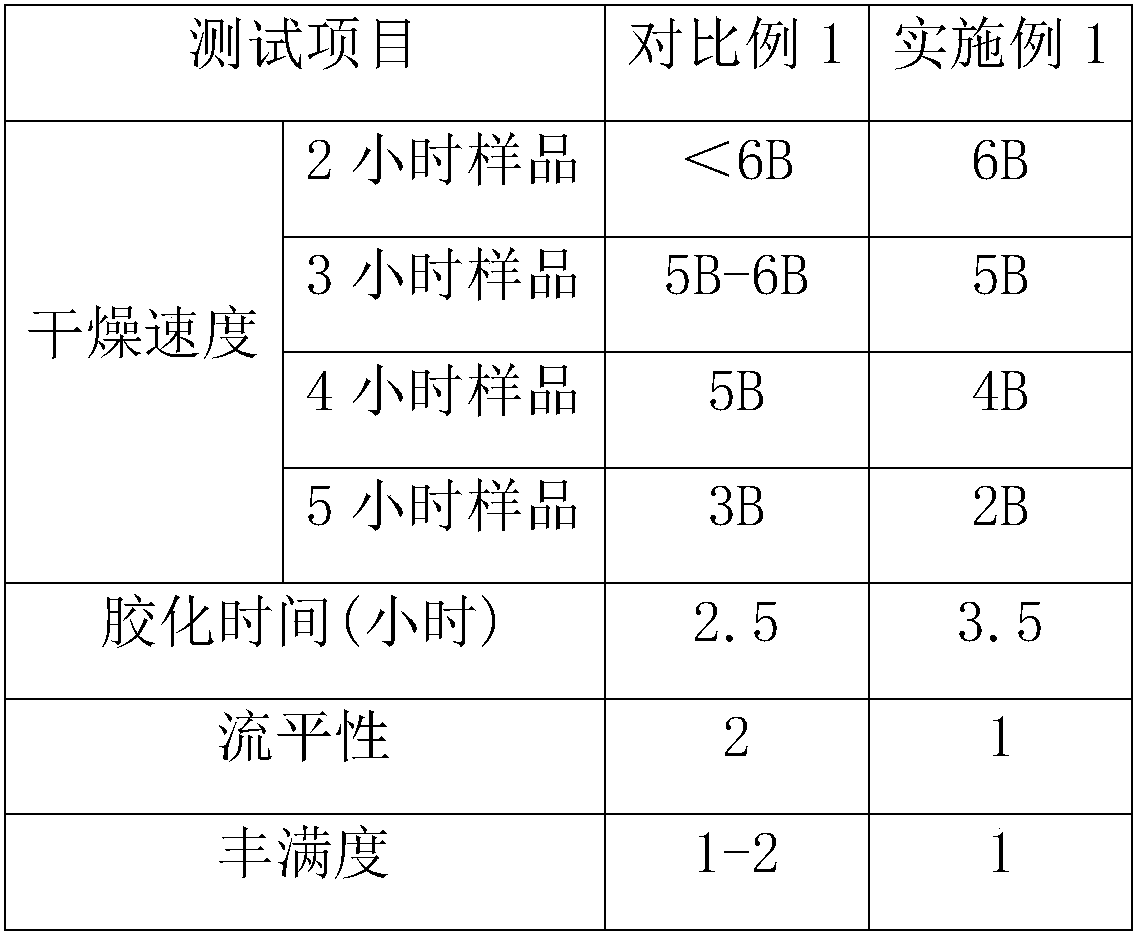

Embodiment 1

[0079] 1) Under nitrogen protection, add 40 parts by weight of butyl acetate into a four-necked flask equipped with a thermometer, stirring and condensing device, and stir to raise the temperature to 90°C;

[0080] 2) In another dropping device, after mixing 15 parts by weight of n-butyl methacrylate, 0.8 parts of hydroxyethyl methacrylate, and 0.05 parts of azobisisobutyronitrile, drop them at a constant speed The method is added into the reactor, the dropwise addition time is 3h, and the reaction system is kept at 90°C;

[0081] 3) Slowly warming up to 125°C, the parts by weight are 25 parts of isobornyl methacrylate, 16 parts of hydroxyethyl methacrylate, 1.5 parts of methacrylic acid and 1.5 parts of tert-butyl peroxybenzoate Mix evenly, add dropwise into the four-necked flask at a constant speed, dropwise for 4 hours, and keep warm for 4 hours after the dropwise addition;

[0082] 4) The temperature was lowered to 80° C., and the material was discharged to obtain the sam...

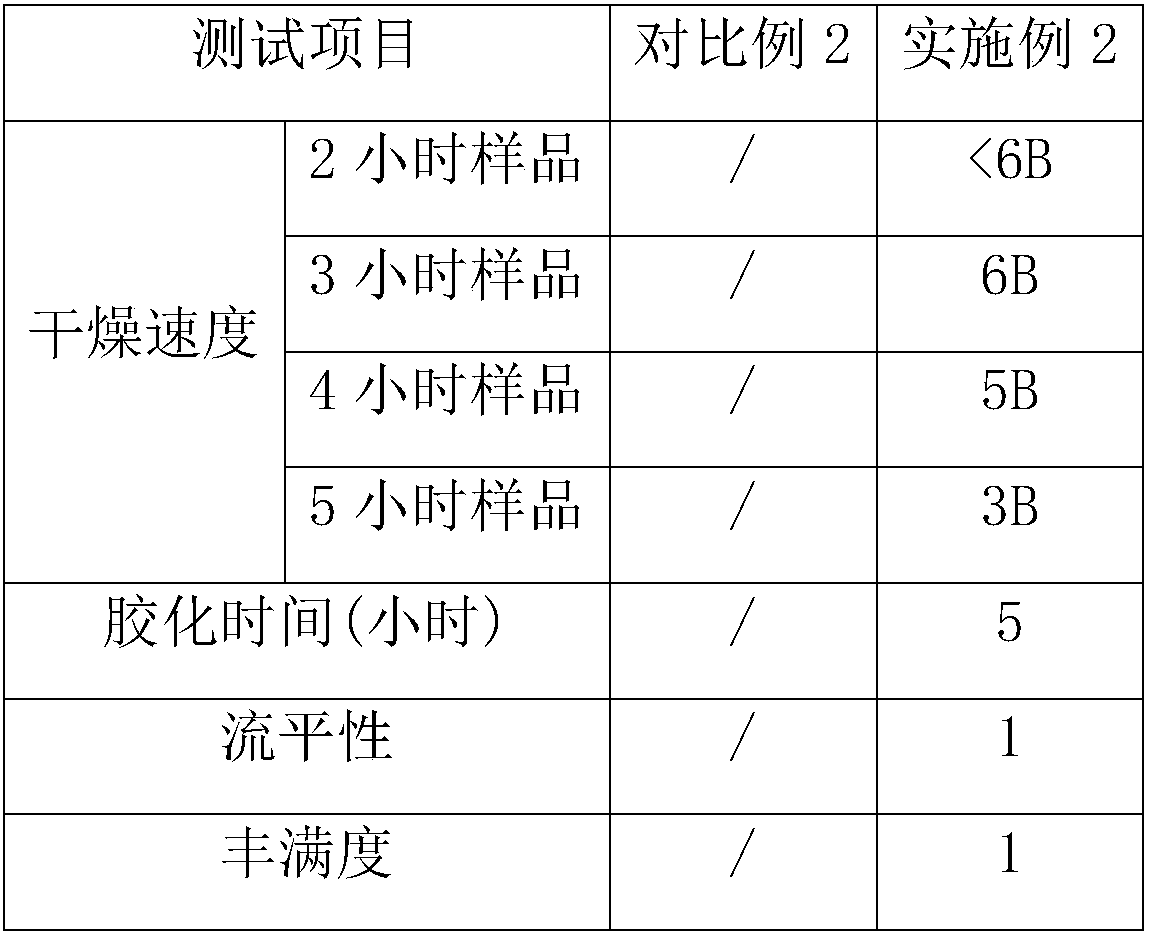

Embodiment 2

[0092] 1) Under nitrogen protection, add 40 parts by weight of xylene into a four-necked flask equipped with a thermometer, stirring and condensing device, and stir to raise the temperature to 100°C;

[0093] 2) In another dropping device, uniformly mix 8 parts by weight of n-butyl acrylate, 1.8 parts of hydroxypropyl methacrylate and 0.1 part of azobisisobutyronitrile, and drop them into a four-necked flask at a constant speed Within 4 hours of dropping time, the reaction system was kept at 100°C;

[0094] 3) Slowly warming up to 130°C, the parts by weight are 19.5 parts of styrene, 19.5 parts of methyl methacrylate, 10.2 parts of hydroxypropyl methacrylate, 0.5 parts of acrylic acid and 2.5 parts of benzoyl peroxide Mix evenly, add dropwise into the four-necked flask at a constant speed, dropwise for 4 hours, and keep warm for 4 hours after the dropwise addition;

[0095] 4) The temperature was lowered to 80° C., and the material was discharged to obtain the sample resin of...

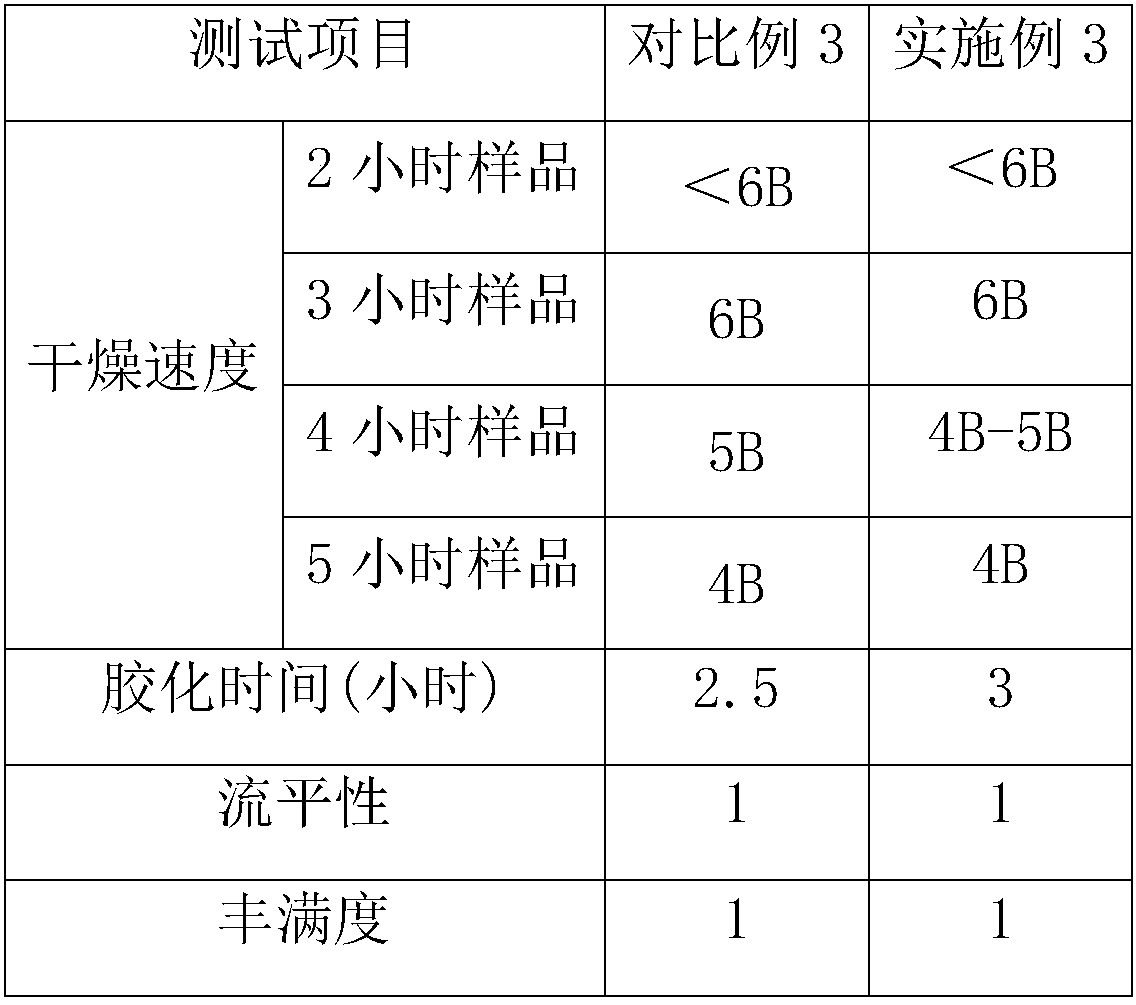

Embodiment 3

[0107] 1) Under nitrogen protection, add 40 parts by weight of butyl acetate into a four-necked flask equipped with a thermometer, stirring and condensing device, and stir to raise the temperature to 90°C;

[0108] 2) In another dropping device, uniformly mix 8 parts by weight of 2-ethylhexyl methacrylate, 1.1 parts of hydroxyethyl acrylate and 0.18 parts of azobisisoheptanonitrile, and add dropwise at a constant speed In the four-necked flask, the dropwise addition time is 4h, and the reaction system is kept at 90°C;

[0109] 3) After slowly heating up to 125°C, add 15.4 parts by weight of n-butyl methacrylate, 20 parts of isobornyl acrylate, 12 parts of hydroxyethyl acrylate, 1 part of methacrylic acid and 2.3 parts of benzene peroxide Mix tert-butyl formate evenly, drop it into the four-necked flask at a constant speed, drop it for 3 hours, and keep it warm for 5 hours after the drop is completed;

[0110] 4) The temperature was lowered to 80° C., and the material was disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com