A kind of hydroxyethyl cellulose hydrogel for adsorbing heavy metal ions and preparation method and application thereof

A technology for hydroxyethyl cellulose to adsorb heavy metals, applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of insufficient adsorption performance of heavy metal ions, etc., and achieve flexible, adjustable and good adsorption performance Regeneration performance, effect of achieving adsorption and enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 0.33g 2.0-generation polyamide-amine dendrimers in 30g / L NaOH solution, add 1.00g hydroxyethyl cellulose to the NaOH solution of polyamide-amine dendrimers while stirring rapidly, and wait for After completely dissolving and mixing uniformly, a mixed solution of polyamide-amine dendrimer and hydroxyethyl cellulose is obtained. 0.59 g of epichlorohydrin was added to the above mixed solution and stirred evenly, and then the mixed reaction solution was placed under a constant temperature of 60° C. for a cross-linking reaction for 4 hours. After the reaction is completed, solid-liquid separation is performed, and the product is washed alternately with water and ethanol for more than 3 times, and then dried at 40° C. to obtain a dry hydroxyethylcellulose-based adsorption hydrogel.

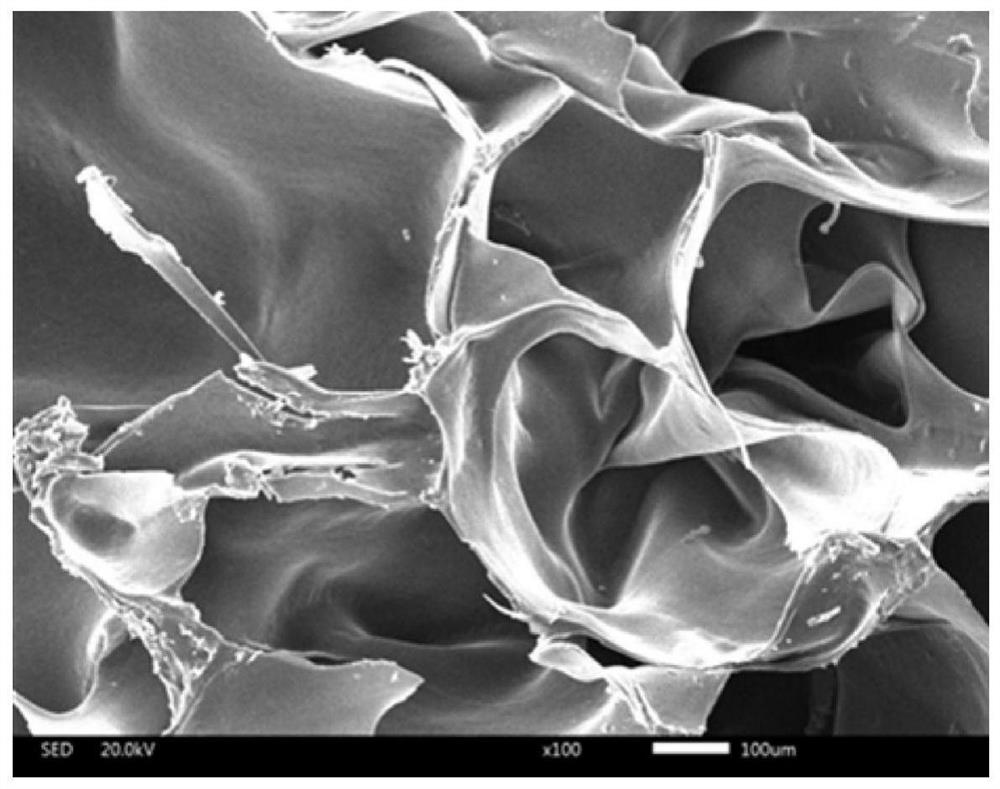

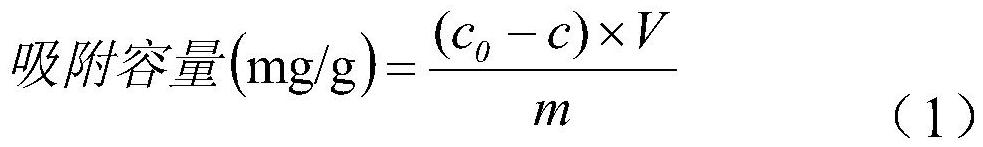

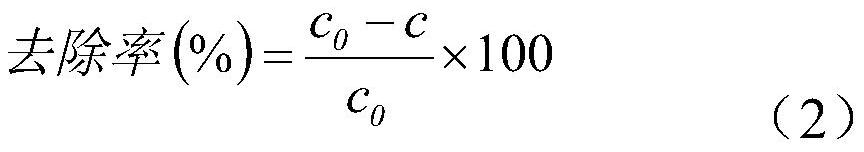

[0027] In order to fully understand the microstructure of the hydrogels prepared in the various embodiments of the present invention, taking the hydrogel product of Example 1 as an examp...

Embodiment 2

[0035] Dissolve 0.23g 2.0-generation polyamide-amine dendrimer in 30g / L NaOH solution, then add 1.00g of hydroxyethyl cellulose to the NaOH solution of the polyamide-amine dendrimer while stirring rapidly, wait for After it is completely dissolved and mixed uniformly, a mixed solution of polyamide-amine dendrimer and hydroxyethyl cellulose is obtained. 0.59 g of epichlorohydrin was added to the above mixed solution and stirred evenly, and then the mixed reaction solution was placed under a constant temperature of 60° C. for a cross-linking reaction for 4 hours. After the reaction is completed, solid-liquid separation is performed, the product is washed alternately with water and ethanol for at least three times, and then dried at 40° C. to obtain a dry hydroxyethyl cellulose-based adsorption hydrogel.

[0036] The adsorption performance test was also carried out on the hydrogel prepared in Example 2. The results showed that when the initial concentration of chromium ions was 5...

Embodiment 3

[0038]Dissolve 0.09g 2.0-generation polyamide-amine dendrimer in 30g / L NaOH solution, then add 1.00g hydroxyethyl cellulose to the NaOH solution of the polyamide-amine dendrimer while stirring rapidly, and wait until After it is completely dissolved and mixed uniformly, a mixed solution of polyamide-amine dendrimer and hydroxyethyl cellulose is obtained. 0.59 g of epichlorohydrin was added to the above mixed solution and stirred evenly, and then the mixed reaction solution was placed under a constant temperature of 60° C. for a cross-linking reaction for 4 hours. After the reaction is completed, solid-liquid separation is performed, and the product is washed alternately with water and ethanol for more than 3 times, and then dried at 50° C. to obtain a dry hydroxyethylcellulose-based adsorption hydrogel.

[0039] The adsorption performance test was also carried out on the hydrogel prepared in Example 3. The results showed that when the initial concentration of chromium ions was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com