OLED display panel and preparation method thereof

A display panel and display area technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as device damage, and achieve the effect of promoting adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

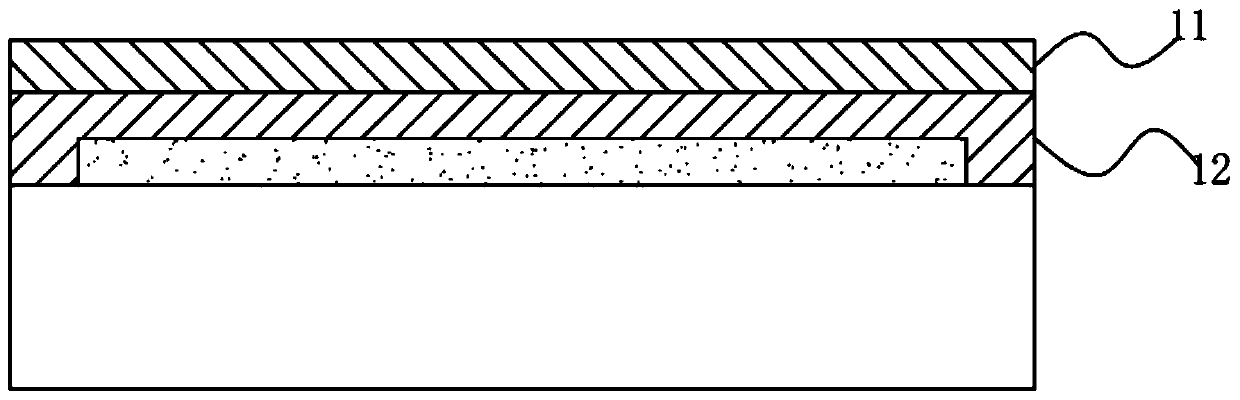

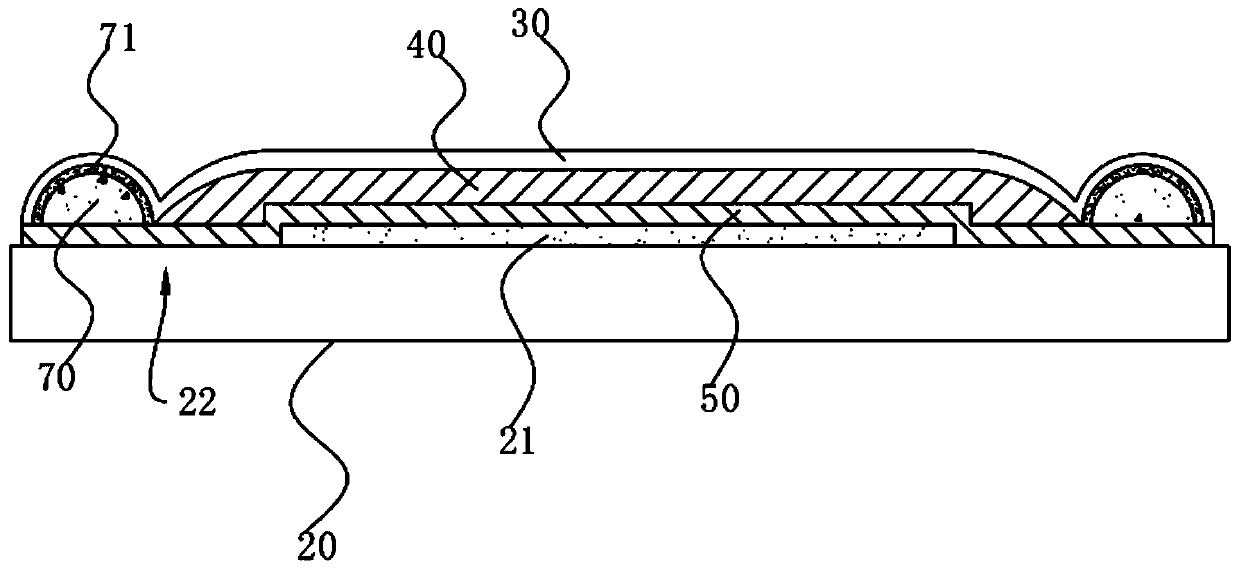

[0043] A kind of OLED display panel, such as figure 2 As shown, the OLED display panel includes a display device board 20 and a dam 70 made of silicone resin; the display device board 20 includes a display area 21 and a non-display area 22, and the dam 70 surrounds the display A region 21 is provided and located at the non-display region 22 .

[0044] Wherein, the OLED display panel further includes an organic buffer layer 40 covering the display area 21, and a first inorganic layer 30 covering the organic buffer layer 40 and the bank 70; the organic buffer layer 40 is located The inner side of the bank dam 70 , and the edge of the organic buffer layer 40 is in contact with the inner side of the bank dam 70 .

[0045] Wherein, the cofferdam 70 includes a weir body, and the surface of the weir body is treated with plasma to form a hardened layer 71 .

[0046] The cofferdam 70 is used to prevent water and oxygen from invading from the side of the OLED display panel, and the s...

Embodiment 2

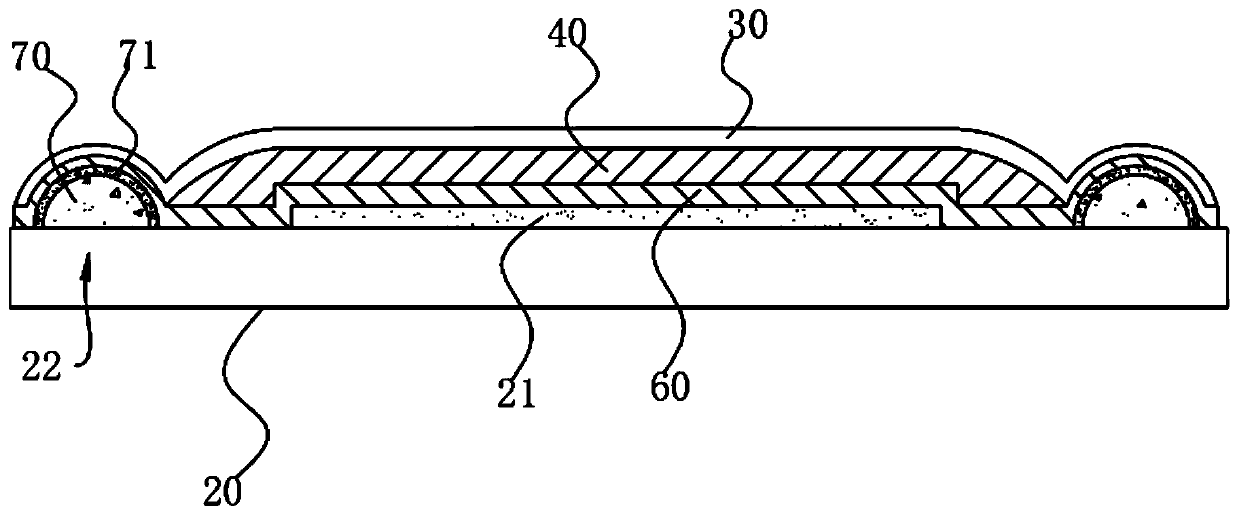

[0059] A kind of OLED display panel, such as image 3 As shown, the difference from Embodiment 1 is that no second inorganic layer 50 is provided, and a third inorganic layer 60 covering the display area 21 and the bank dam 70 is provided on the display device panel 20 , the organic buffer layer 40 is disposed on the third inorganic layer 60 .

[0060] Further, the edge of the first inorganic layer 30 and the edge of the third inorganic layer 60 are located outside the bank 70, and the edge of the first inorganic layer 30 and the third inorganic layer 60 The distance between the edges of each and the outer side of the cofferdam 70 in the horizontal direction is 1-3 microns.

[0061] In one embodiment, the distance between the edge of the first inorganic layer 30 and the edge of the third inorganic layer 60 and the outside of the bank 70 in the horizontal direction is 1 μm.

Embodiment 3

[0063] Based on the OLED display panel in Example 1, a method for preparing an OLED display panel is proposed, such as Figure 4 shown, including the following steps:

[0064] S10, providing a display device board 20;

[0065] S20, forming a bank dam 70 surrounding the display area 21 at the non-display area 22 of the display device panel 20;

[0066] S30, using plasma to perform surface treatment on the surface of the cofferdam 70 to form a hardened layer 71;

[0067] S40, forming an organic buffer layer 40 covering the display area 21 inside the bank 70;

[0068] S50 , forming the first inorganic layer 30 covering the organic buffer layer 40 and the banks 70 on the organic buffer layer 40 .

[0069] Further, before the step S20, the method for preparing the OLED display panel further includes:

[0070] S60 , forming a second inorganic layer 50 covering the display area 21 and extending to the non-display area 22 on the display device panel 20 .

[0071] Such as Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com