Food microwave three-dimensional printing method and printer

A three-dimensional printer and three-dimensional printing technology, applied in the food field, can solve the problems of easy collapse of printed products, difficult to print hollow three-dimensional structures, incomplete curing, etc., and achieve the effects of stable microwave output, prevention of microwave leakage and diffusion, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

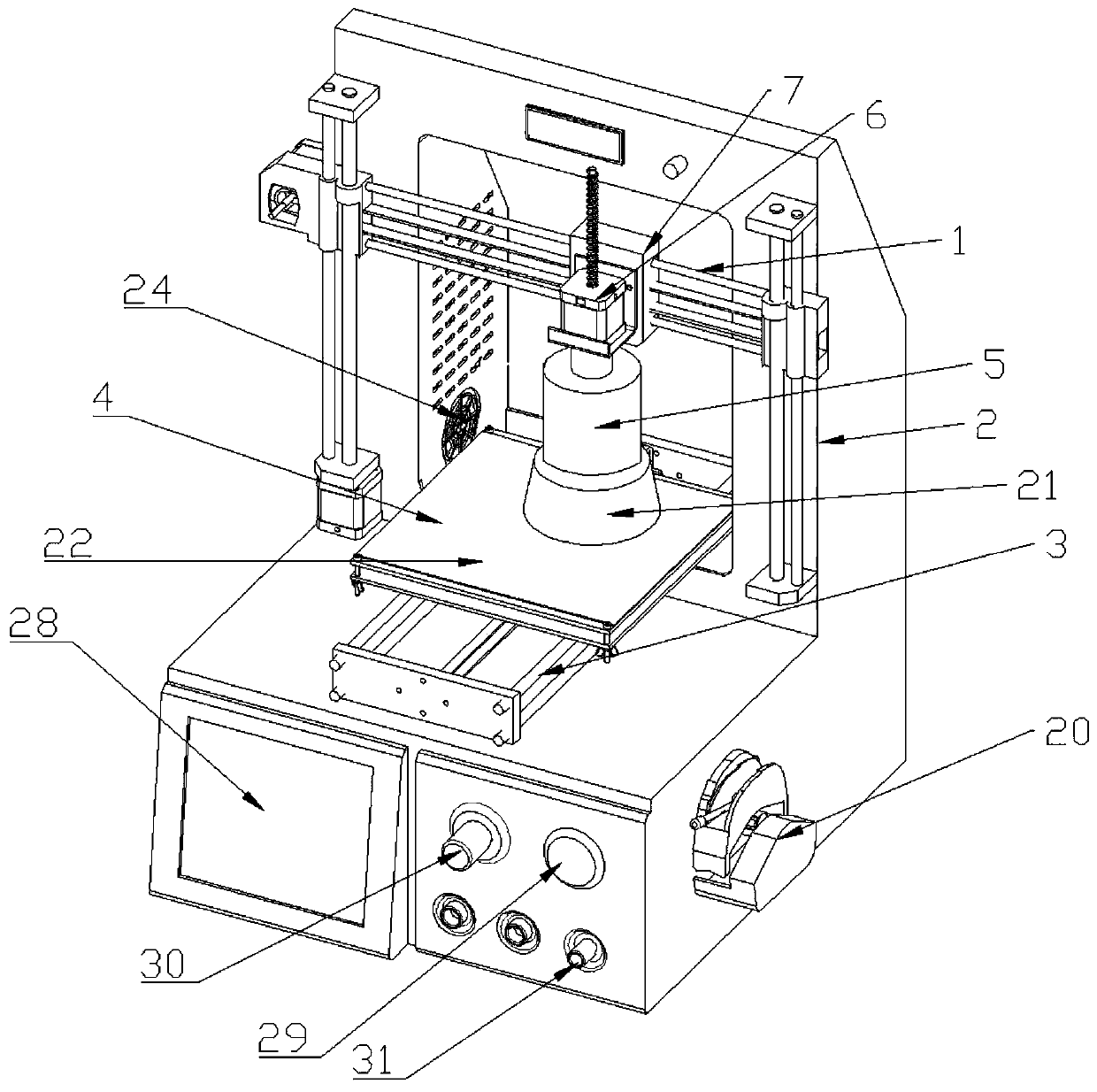

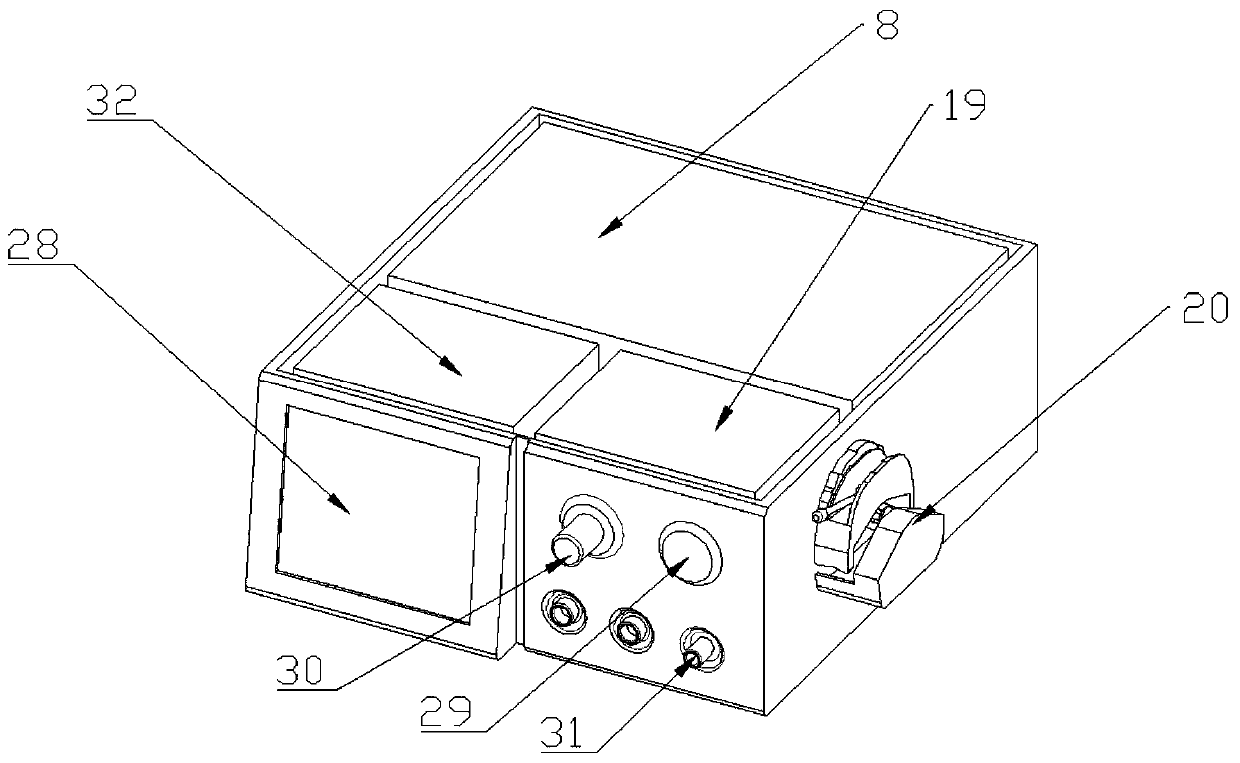

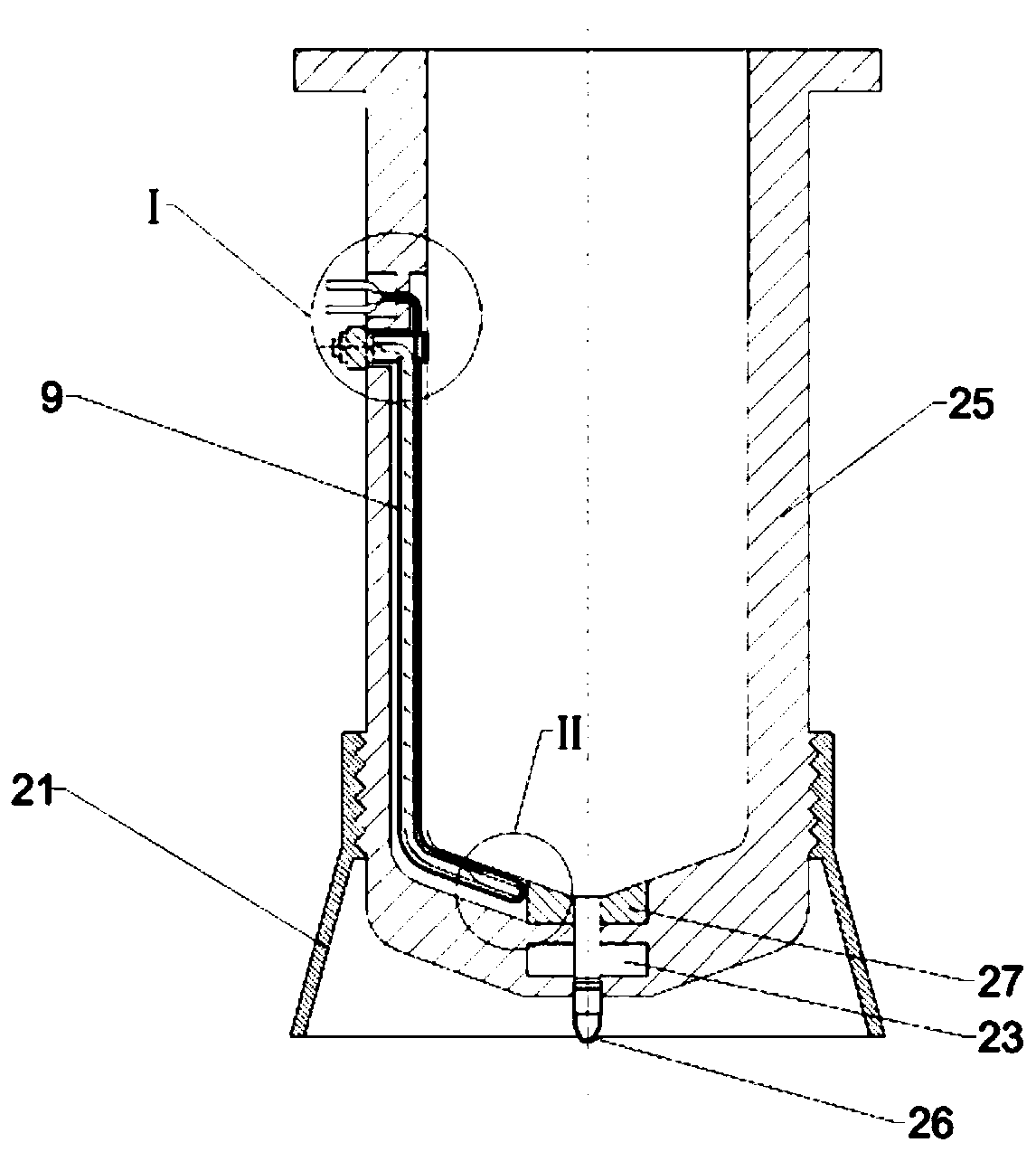

[0048] This embodiment provides a food three-dimensional printer, see figure 1 , the food three-dimensional printer includes a printing drive mechanism, a microwave heating unit, an anti-leakage unit, an extrusion unit, a control unit and a printing platform; wherein, the microwave heating unit includes a microwave solid-state source, a microwave heating probe; the extrusion unit includes a barrel, The barrel wall of the barrel is a partially hollow structure, and the microwave heating probe is located in the hollow structure of the barrel wall.

[0049] The food three-dimensional (3D) printer is designed on the basis of a 3D printer with a printing drive mechanism, including peripheral stainless steel frame materials, X-axis guide rod 1, Z-axis guide rod 2, Y-axis guide rod 3, printing platform 4, Barrel 5, lead screw stepping motor 6, fixing seat 7 and other printing drive installation mechanisms.

[0050] like figure 1 , figure 2 , image 3 As shown, the microwave heat...

Embodiment 2

[0082] This embodiment provides a three-dimensional printing method for food, the method adopts the food three-dimensional printer given in the first embodiment, and the method includes:

[0083] According to the type of material to be printed, a barrel of non-absorbing material with a corresponding size is selected to be installed on the food 3D printer;

[0084] Specifically, (1) first measure the dielectric constant ε and magnetic permeability μ of the material to be printed;

[0085]

[0086] Input the dielectric constant ε and permeability μ of the material to be printed into the above formula to calculate the input impedance z of the material to be printed in , in the above formula, z in is the input impedance of the material; c is the speed of light in vacuum, c=3×10 8 m / s; ω=2πf, f is the microwave frequency,

[0087] μ 0 is the permeability in free space, 4π×10 -7 H / m; μ is the magnetic permeability of the material; ε 0 is the dielectric constant in free spac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com