Self-compacting leveling concrete and preparation method and usage thereof

A concrete and self-compacting technology, which is applied in the direction of construction, building structure, floor, etc., can solve the problems of easy cracking, low tensile bonding strength, and unstable quality of self-leveling concrete, so as to improve tool turnover efficiency and improve The effect of small fluctuations in mechanical properties, quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] In another aspect of the present invention, the present invention provides a method for preparing the aforementioned self-compacting leveling concrete, the method comprising: mixing various raw materials to obtain the self-compacting leveling concrete.

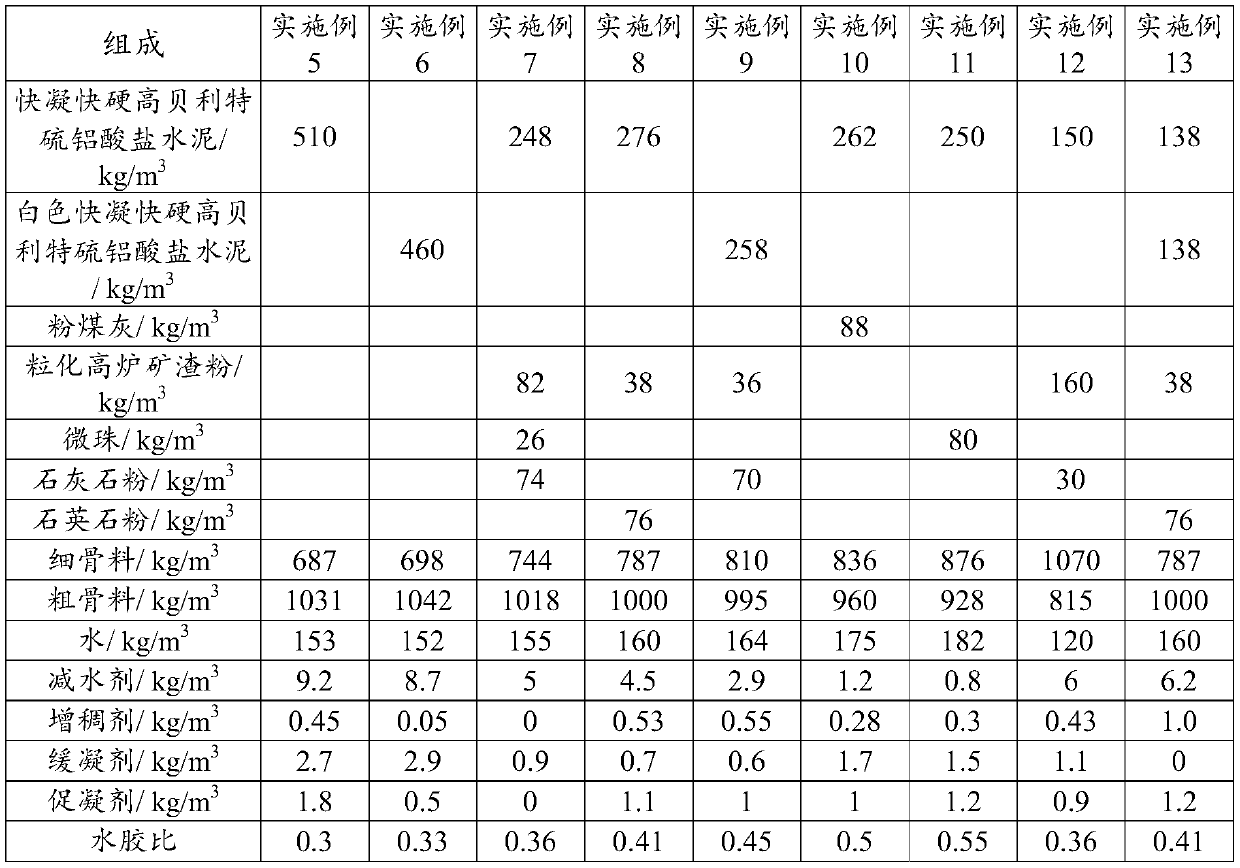

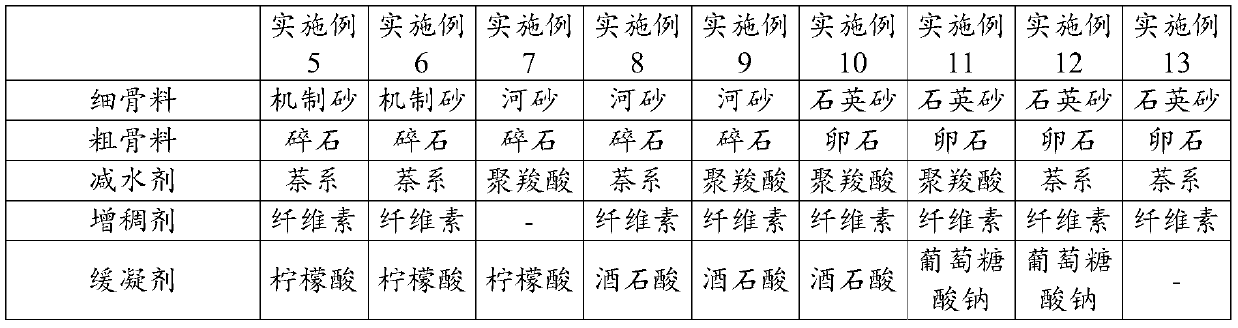

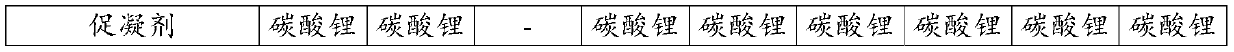

[0065] In some embodiments of the present invention, the preparation method of self-compacting leveling concrete comprises: fast-setting rapid-hardening high belite sulfoaluminate cement or white fast-setting rapid-hardening high belite sulphoaluminate cement, mineral The admixture, fine aggregate, coarse aggregate, water, water reducer, retarder, and accelerator are mixed together to obtain self-compacting leveling concrete.

[0066] In another aspect of the present invention, the present invention provides a use of the aforementioned self-compacting leveling concrete in the manufacture of industrial workshop floors, warehouse floors, parking lot floors, art floors or terrazzo floors.

Embodiment 1

[0073] Self-compacting leveling concrete consists of the following raw materials:

[0074] Fast setting rapid hardening high belite sulfoaluminate cement 510kg / m 3 , fine aggregate 687kg / m 3 , coarse aggregate 1031kg / m 3 , water 153kg / m 3 , water reducer 9.2kg / m 3 .

Embodiment 2

[0076] Self-compacting leveling concrete consists of the following raw materials:

[0077] Fast setting rapid hardening high belite sulfoaluminate cement 250kg / m 3 , fine aggregate 698kg / m 3 , Coarse aggregate 928kg / m 3 , water 152kg / m 3 And water reducer 0.8kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com