Ecological anti-root-rot slow-release fertilizer and preparation method thereof

A technology of anti-root rot and slow-release fertilizer, applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems such as the release rate, method and duration cannot be well controlled, the fertilization method and environmental conditions are greatly affected, etc. , to achieve a good slow-release effect, reduce the use of pesticides, and stabilize nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

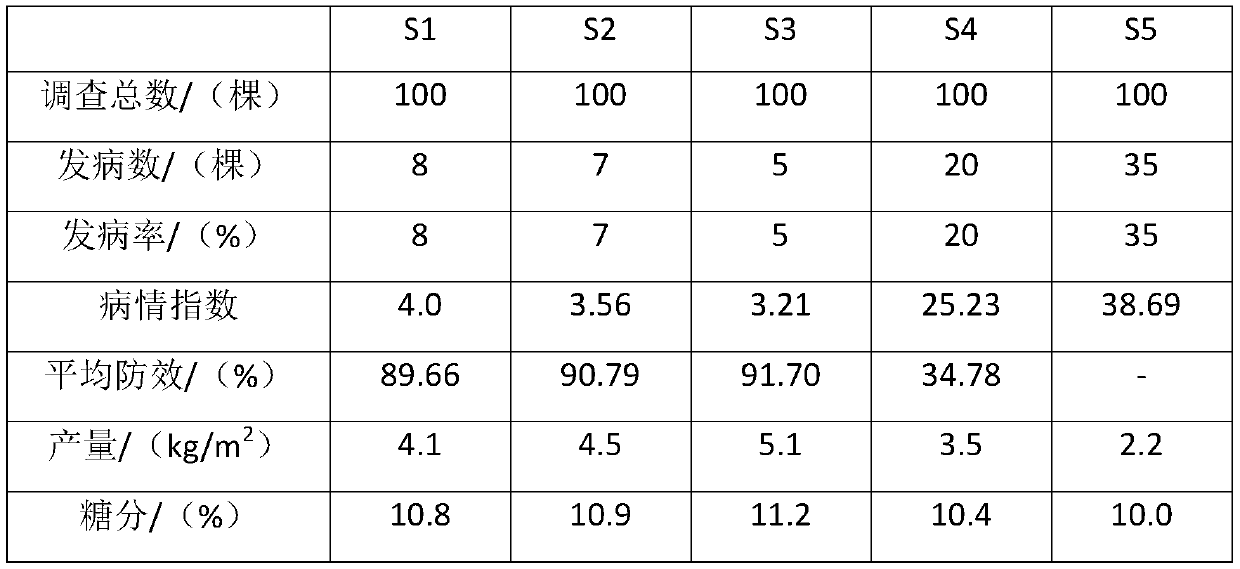

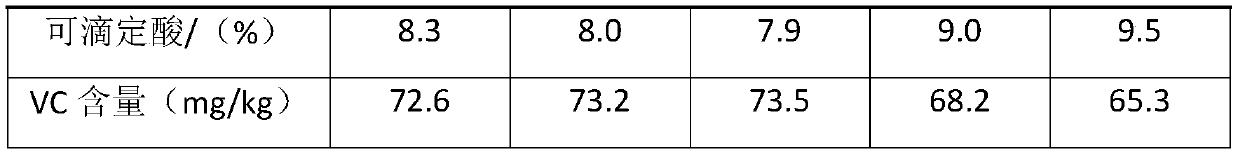

Embodiment 1

[0022] An ecological slow-release fertilizer resistant to root rot, prepared from the following raw materials in parts by weight: 20 parts of nitrogen fertilizer, 10 parts of phosphate fertilizer, 8 parts of potassium fertilizer, 10 parts of humic acid, 3 parts of medium and trace elements, and 3 parts of attapulgite , 3 parts of borax, 1 part of calcium sulfate, 2 parts of lime powder, 0.8 part of calcium chloride, 0.1 part of cotton wool, 5 parts of coating agent; After stirring for 1 hour in hot water at 80°C, add 2% acetic acid solution to form a 5% cornstarch solution, stir for 40 minutes, and mix KH560, which accounts for 5% of the starch mass, and 1% of the starch mass. The lignin was dissolved in 2 mL of ethanol, then added to the starch acetic acid solution, continued to stir, and kept at a temperature of 60°C for 4 hours. After the reaction was completed, the solution was distilled off the solvent under reduced pressure to obtain a solid, which was then dried in vacuo...

Embodiment 2

[0031] An ecological slow-release fertilizer resistant to root rot, which is prepared from the following raw materials in parts by weight: 25 parts of nitrogen fertilizer, 13 parts of phosphate fertilizer, 9 parts of potassium fertilizer, 15 parts of humic acid, 7 parts of medium and trace elements, and 4 parts of attapulgite , 4 parts of borax, 2 parts of calcium sulfate, 3 parts of lime powder, 1.5 parts of calcium chloride, 0.3 part of cotton wool, 8 parts of coating agent; After stirring for 1 hour in hot water at 80°C, add 2% acetic acid solution to form a 5% cornstarch solution, stir for 40 minutes, and mix KH560, which accounts for 5% of the starch mass, and 1% of the starch mass. The lignin was dissolved in 2.5 mL of ethanol, then added to the starch acetic acid solution, continued to stir, and kept at a temperature of 60°C for 4.5 hours. After the reaction was completed, the solution was distilled off the solvent under reduced pressure to obtain a solid, which was then...

Embodiment 3

[0040] An ecological slow-release fertilizer resistant to root rot, which is prepared from the following raw materials in parts by weight: 30 parts of nitrogen fertilizer, 16 parts of phosphate fertilizer, 10 parts of potassium fertilizer, 20 parts of humic acid, 10 parts of medium and trace elements, and 5 parts of attapulgite , 5 parts of borax, 3 parts of calcium sulfate, 4 parts of lime powder, 2.5 parts of calcium chloride, 0.5 part of cotton wool, 10 parts of coating agent; After stirring for 1 hour in hot water at 80°C, add 2% acetic acid solution to form a 5% cornstarch solution, stir for 40 minutes, and mix KH560, which accounts for 5% of the starch mass, and 1% of the starch mass. The lignin was dissolved in 3mL of ethanol, then added to the starch acetic acid solution, continued to stir, and kept at a temperature of 60°C for 5 hours. After the reaction was completed, the solution was evaporated to remove the solvent under reduced pressure to obtain a solid, which was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com