Sodium-cooled fast reactor intermediate-circuit passive-accident residual heat removal system

A waste heat removal system and intermediate loop technology, applied in reactors, nuclear power generation, cooling devices, etc., can solve problems such as waste of efficiency, weakening the ability of independent heat exchangers to establish natural circulation, and inability to fully guarantee the core and heat removal capabilities , to achieve the effect of improving the ability to establish natural circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments will be described in detail below in conjunction with the accompanying drawings.

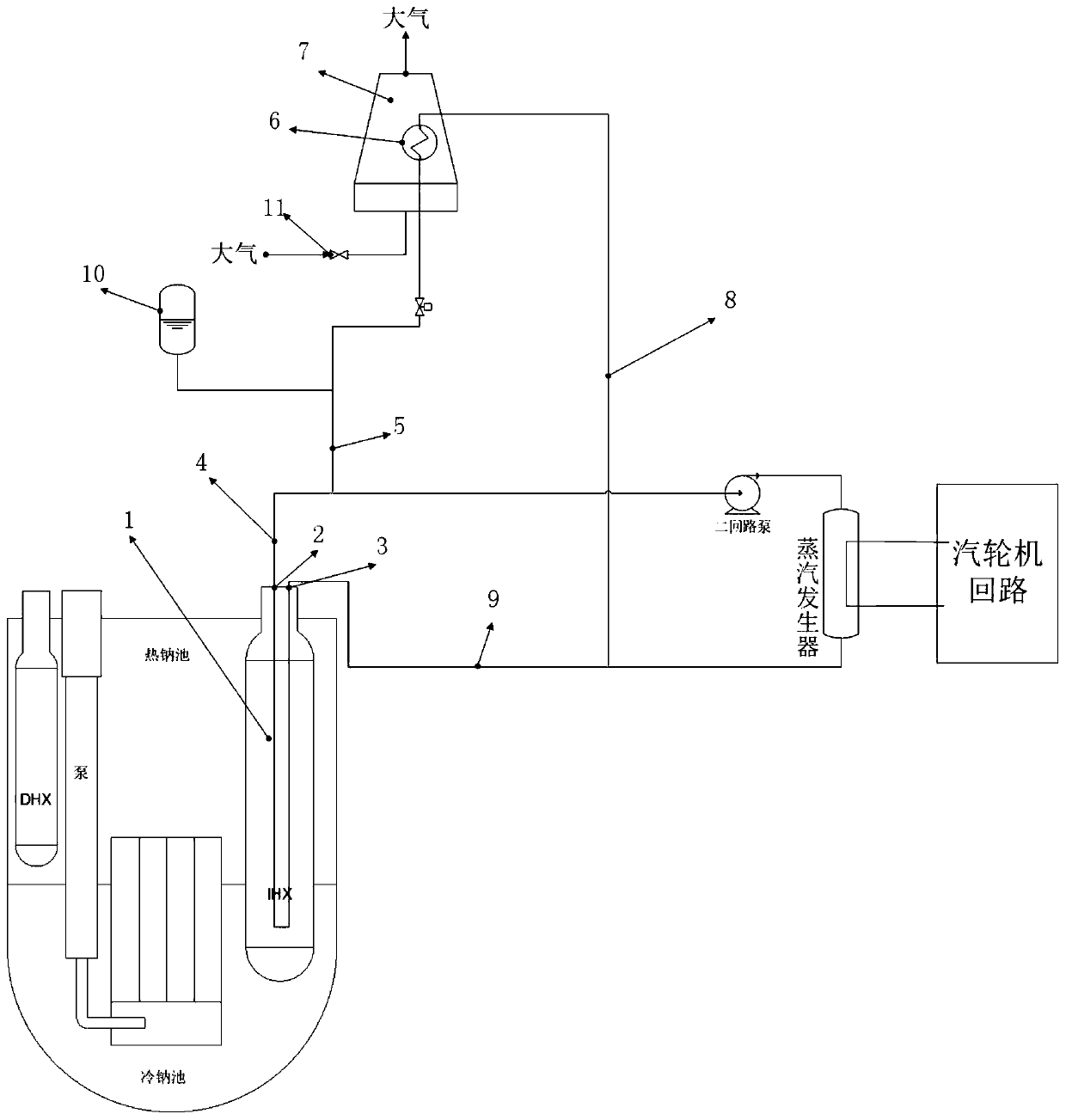

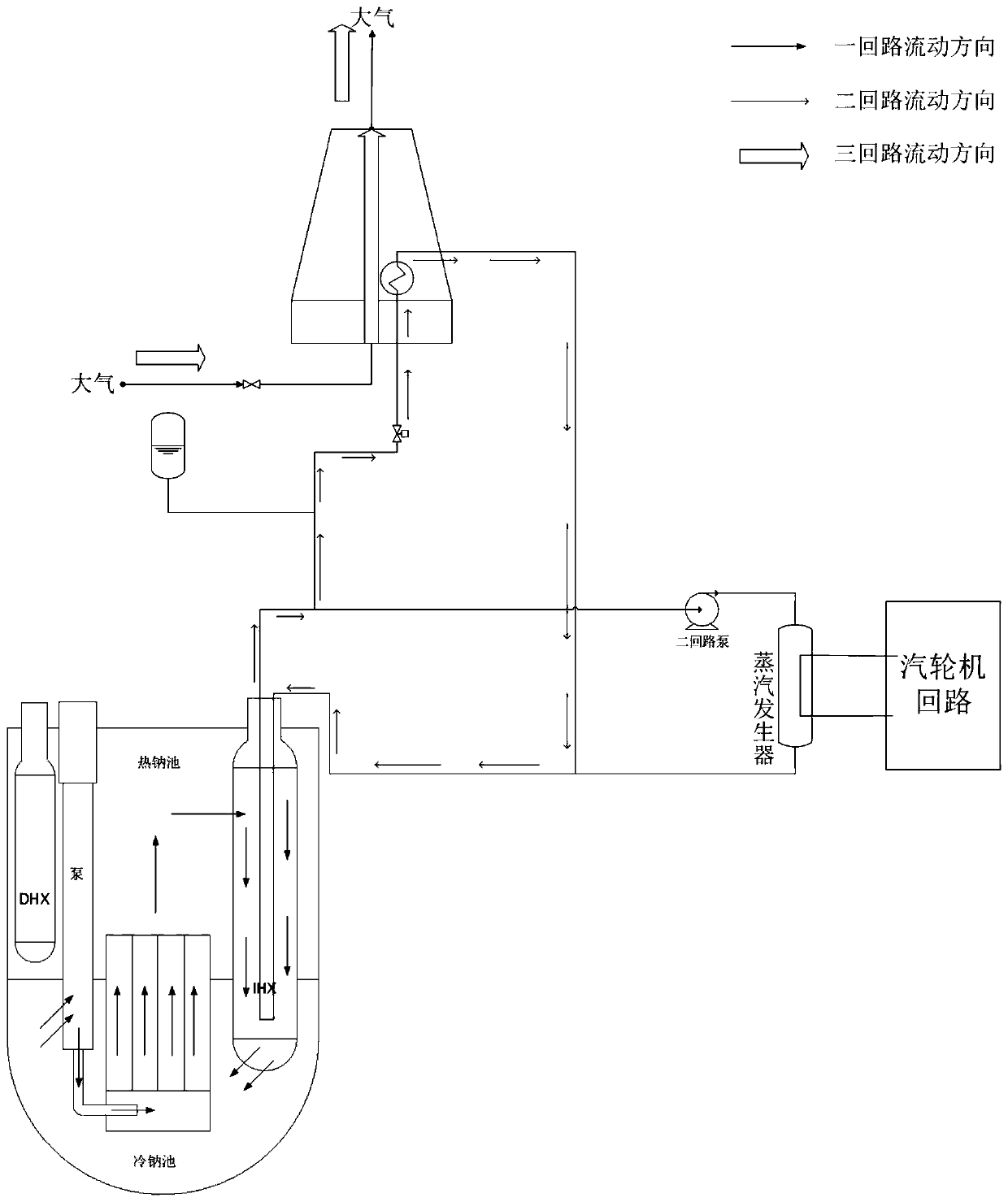

[0021] Such as figure 1 Shown is a specific structural schematic diagram of the intermediate circuit passive waste heat removal system of the present invention. In the figure, the intermediate heat exchanger (IHX) 1 inside the core is connected to the beginning end 4 of the intermediate circuit heat pipe section through the secondary side outlet 2, and the beginning end 4 of the intermediate circuit heat pipe section is connected to the pipe side of the air heat exchanger (AHX) 6 through the pipe 5 The inlets are connected, and the pipes 4 and 5 together constitute the heat pipe section of the passive waste heat removal system of the intermediate circuit. The heat pipe section 5 is connected to the expansion tank 10, and the heat pipe section 5 is connected to the pipe-side inlet of the air heat exchanger (AHX) 6. In order to achieve natural circulation, the arrangement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com