Method for depositing InGaN film on Si(100) substrate via double-optical-path pulse laser

A pulsed laser deposition, dual optical path technology, applied in circuits, ion implantation plating, coatings, etc., can solve problems such as difficult to prepare alloy films, and achieve the effect of saving equipment procurement costs, reducing production costs, and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific embodiments.

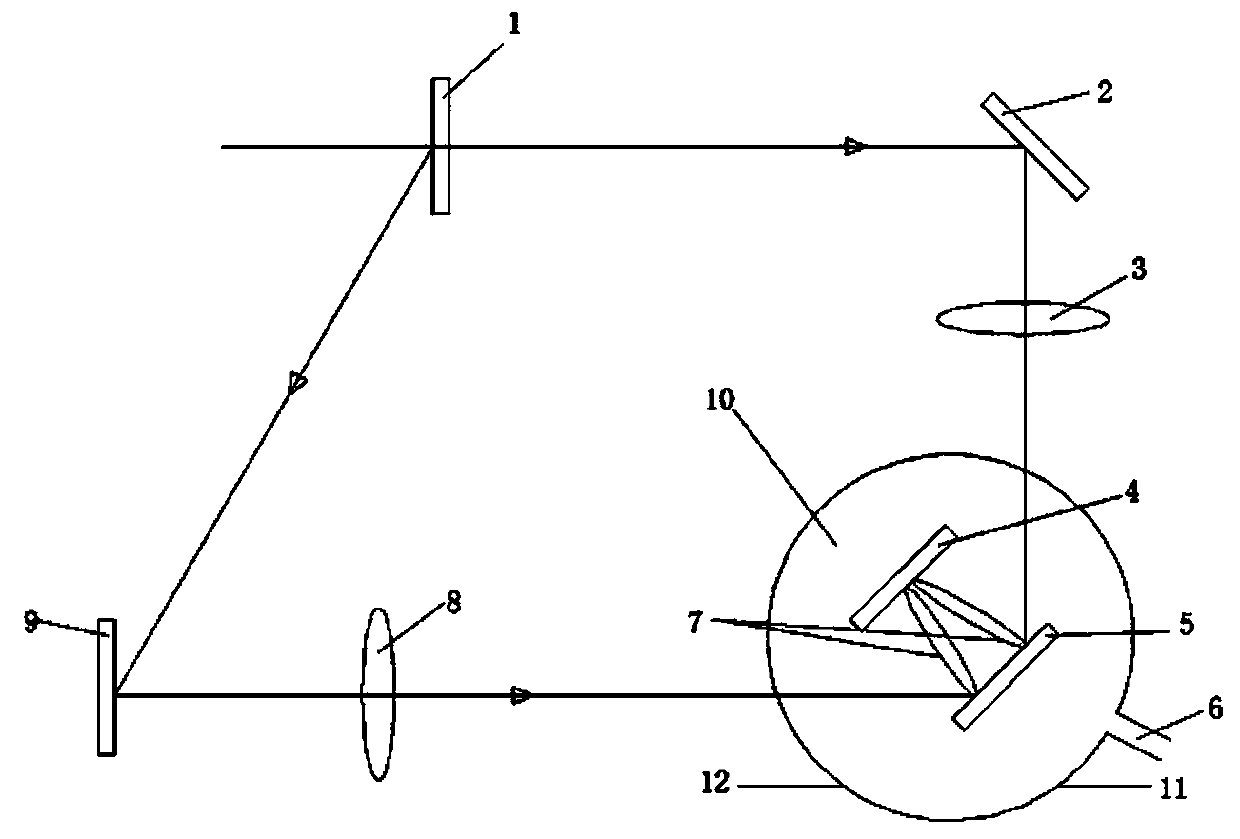

[0039] Please refer to figure 1 , a dual optical path pulsed laser deposition device, including a growth chamber cavity 10, a base is provided in the central area below the growth chamber cavity 10, and four evenly arranged turntables for placing targets are arranged on the base 5. The base and the turntable 5 are respectively driven to rotate by the driving mechanism, so that the target can rotate with the turntable 5; a mechanical pump connection valve 11 and a molecular pump are also provided on the lower side wall or bottom wall of the growth chamber cavity 10 Connect the valve 12 so as to connect the mechanical pump and the molecular pump to evacuate the growth chamber cavity 10; an auxiliary gas pipeline 6 is provided at the middle and lower position of the growth chamber cavity 10 to replenish O in time during the coating process. 2 and N 2 A quartz window is respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com