Packaging structure and packaging method

A packaging structure and packaging method technology, applied in the direction of transportation and packaging, packaging, wrapping paper, etc., can solve the problems of increasing packaging costs, polluting the display panel, poor adsorption, etc., and achieve effective positioning of packaging, low static effect, flatness high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

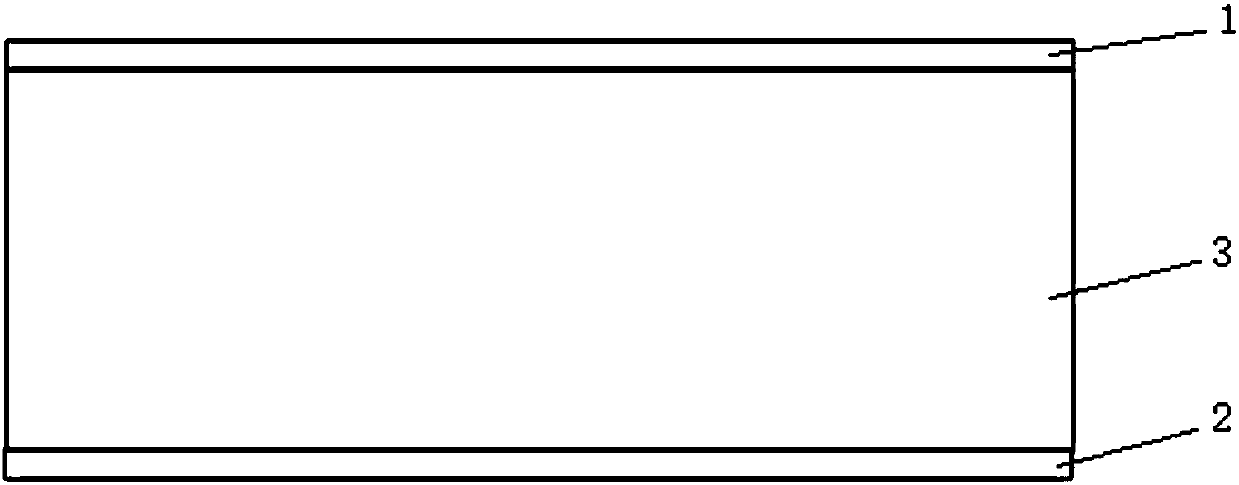

[0062] The embodiment of the present invention proposes a kind of co-extruded biaxially stretched synthetic paper, such as figure 2 As shown, it has a three-layer superimposed composite structure, including a first surface layer 1, a second surface layer 2 and a core layer 3, the core layer 3 is arranged between the first surface layer 1 and the second surface layer 2, and the first surface layer 1 is a bearing layer. The thickness of the first skin 1 is 5-30 microns, preferably 10-20 microns, and the second skin 2 may have the same thickness and composition as the first skin 1 . The surface roughness (Ra value) of the first surface layer 1 of the synthetic paper is less than 0.100 micron (measured according to ISO12085 "geometric product specification" by German Marr surface roughness measuring instrument (model: Marsurf M300C), preferably less than 0.050 micron . The density of the synthetic paper is 0.50-0.90g / cm3, preferably 0.60-0.70g / cm3.

[0063] The raw materials of...

Embodiment 2

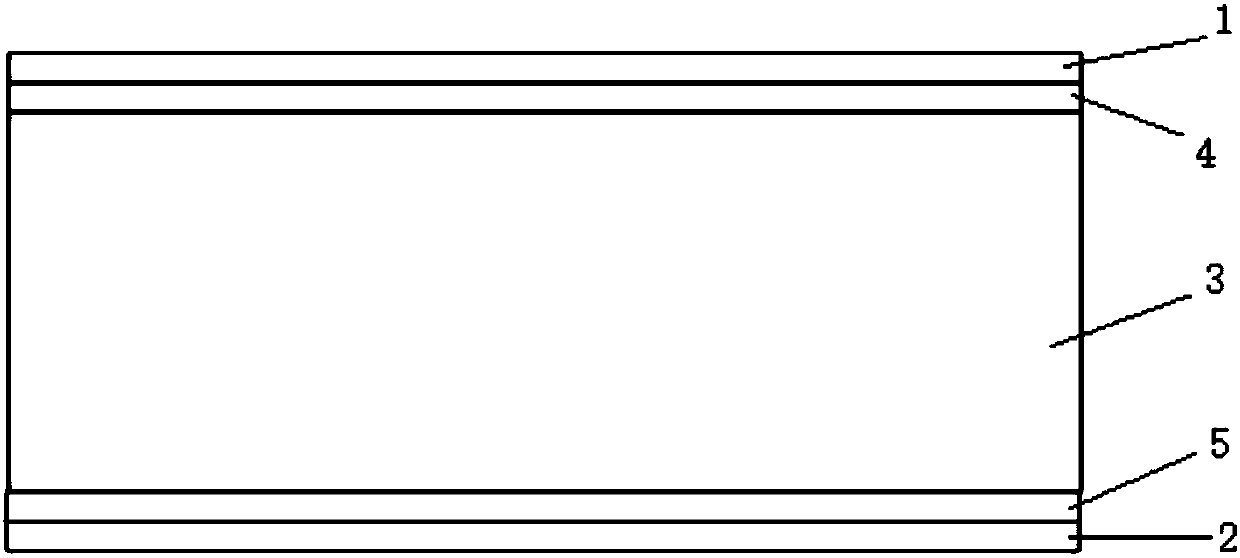

[0071] In Example 1 of the present invention, a co-extruded biaxially oriented synthetic paper with a three-layer laminated composite structure is specifically described. In another embodiment of the present invention, as image 3 As shown, the co-extruded biaxially oriented synthetic paper has a five-layer superimposed composite structure, including the first surface layer 1, the first surface layer 4, the core layer 3, the second surface layer 5 and the second surface layer 2, and the first surface layer 1 is Bearer layer. The thickness of the first skin 1 is 5-30 microns, preferably 10-20 microns, and the second skin 2 may have the same thickness and composition as the first skin 1 . The surface roughness (Ra value) of the first surface layer 1 of the synthetic paper is less than 0.100 micron, preferably less than 0.050 micron. The density of the synthetic paper is 0.50-0.90g / cm3, preferably 0.60-0.70g / cm3.

[0072] Compared with the synthetic paper of Example 1, the fir...

Embodiment 3

[0075] refer to Figure 4 , in the manufacture method of above-mentioned co-extruded biaxially stretched synthetic paper of the present invention, comprise the following steps:

[0076] Extrusion step: the raw materials of each layer in the multi-layer structure of synthetic paper are uniformly stirred at room temperature, and the stirred raw materials of each layer are respectively extruded by their respective extruders at a working temperature of 200-260 ° C according to the multi-layer The laminated structure is melt-extruded into a plurality of flow channels stacked in the T-shaped die, and co-extruded to form a composition laminate, which flows out through the T-shaped die.

[0077] For the synthetic paper of manufacturing example 1, the T-shaped module includes three runners arranged in layers, the raw material of the first surface layer 1 after stirring enters the upper runner of the T-shaped die head, and the raw material of the second surface layer 2 after stirring en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com