Water-soluble modified phenolic resin for bamboo impregnation and preparation method thereof

A phenolic resin and water-soluble technology, which is applied in the field of water-soluble modified phenolic resin impregnated with bamboo and its preparation, can solve the problems of increased water content, affecting the hot-pressing performance of bamboo, and difficulty in curing completely, so as to achieve fast curing speed and benefit For impregnation, effect of low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

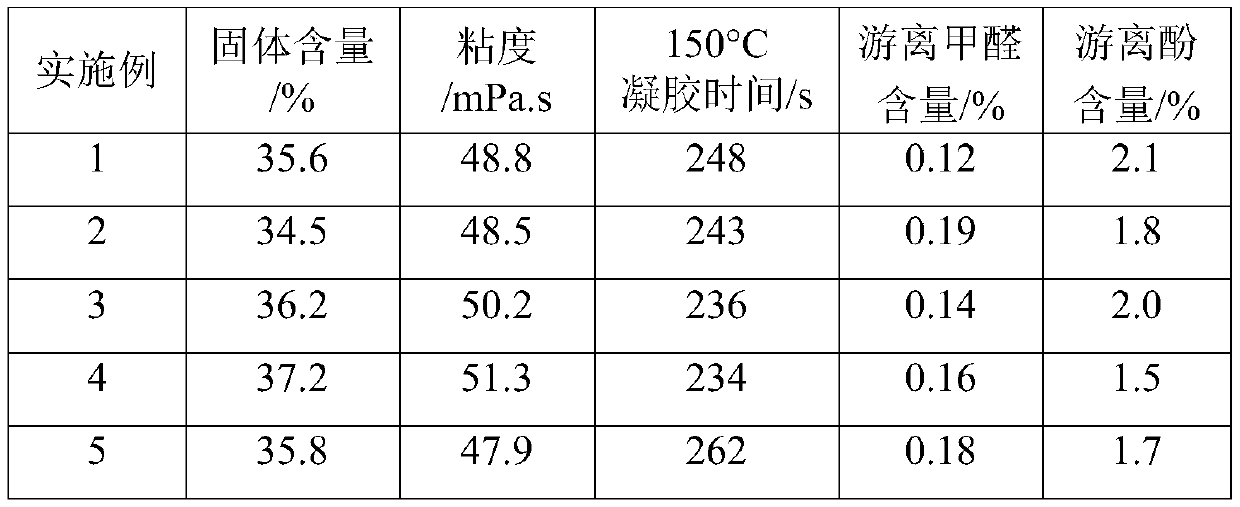

Examples

Embodiment 1

[0034] Add 1000kg of industrial phenol, 1000kg of 37% industrial formaldehyde in the first batch, 100kg of urea in the first batch and 80kg of industrial methanol in the reaction kettle, stir for 20min; heat up to 55°C, keep warm at this temperature for 30min, and gradually add the first Batch 30% sodium hydroxide 400kg (add within 30min), keep the temperature at 55°C when adding, turn on cooling water to cool if necessary, after adding, keep the temperature at 55°C for 30min; add the second batch of industrial formaldehyde solution 600kg , heat up to 80°C, heat preservation reaction for 30min; gradually add the second batch of 30% sodium hydroxide aqueous solution 600kg (completely added within 30min), heat up to 90°C, add the second batch of urea 60kg, heat preservation reaction for 40min, use 10 Add 2800 kg of water after measuring the viscosity at 25° C. for 2 seconds, and then add 2800 kg of water, stir for 30 minutes; pass cooling water, quickly cool down to 38° C., and d...

Embodiment 2

[0036] Add 1000kg of industrial phenol, 1200kg of 37% industrial formaldehyde in the first batch, 120kg of urea in the first batch and 70kg of industrial methanol in the reaction kettle, stir for 22min; heat up to 56°C, keep warm at this temperature for 35min, and gradually add the first Batch 30% sodium hydroxide 500kg (add within 30min), keep the temperature at 56°C when adding, turn on cooling water to cool if necessary, after adding, keep the temperature at 56°C for 35min; add the second batch of industrial formaldehyde solution 800kg , heat up to 81°C, heat preservation reaction for 35min; gradually add the second batch of 30% sodium hydroxide aqueous solution 500kg (completely added within 30min), heat up to 91°C, add the second batch of urea 50kg, heat preservation reaction for 50min, use 10 Add 3000 kg of water after measuring the viscosity at 25° C. for 2 seconds, and then add 3000 kg of water, stir for 35 minutes; pass cooling water, quickly cool down to 38° C., and d...

Embodiment 3

[0038] Add 1000kg of industrial phenol, 950kg of 37% industrial formaldehyde in the first batch, 60kg of urea in the first batch and 60kg of industrial methanol in the reaction kettle, stir for 25min; raise the temperature to 57°C, keep it warm for 40min at this temperature, and gradually add the first Batch 300% potassium hydroxide 300kg (add within 30min), keep the temperature at 57°C when adding, turn on cooling water to cool if necessary, after adding, keep the temperature at 57°C for 40min; add the second batch of industrial formaldehyde solution 900kg , heat up to 82°C, heat preservation reaction for 40min; gradually add the second batch of 30% potassium hydroxide aqueous solution 700kg (completely added within 30min), heat up to 92°C, add the second batch of urea 120kg, heat preservation reaction for 60min, use 10 Add 3500 kg of water after measuring the viscosity at 25° C. for 2 seconds, and then add 3500 kg of water, stir for 40 minutes; pass cooling water, quickly coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Gel time | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com