Solid detergent without ethoxylates

A technology for ethoxylates and solid detergents, applied in the field of solid detergents without ethoxylates, can solve problems such as human health effects, carcinogenic risks, etc., achieve rapid and complete biodegradation, enhance decontamination ability, reduce irritating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

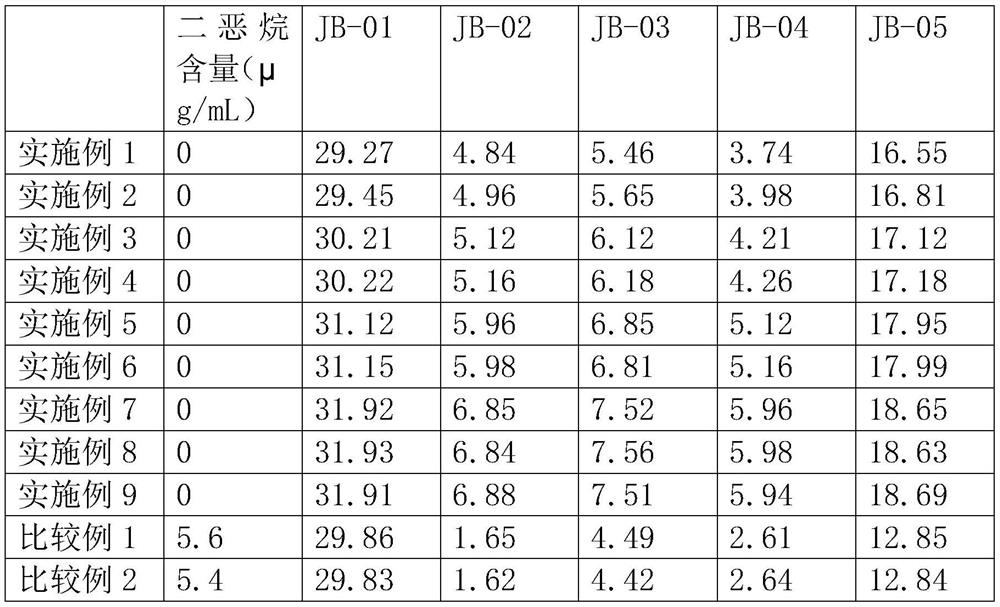

Examples

Embodiment 1

[0075] A solid detergent without ethoxylates, comprising the following components in parts by mass:

[0076] Mono-C12-18-Alkyl Sulfate Sodium Salt 28kg; Polyvinyl Alcohol 24kg; Deionized Water 13kg; Alkyl Glucosides 12kg; Cocamidopropyl Betaine 12kg; Cocamidopropyl Oxide 7kg; Sodium Citrate 5kg; polyether modified silicone oil 5kg; Sapinberry extract 4kg; silicon dioxide 4kg; glycerin 4kg; citric acid 2kg.

[0077] In this example, the polyvinyl alcohol is polyvinyl alcohol with a product number of 2699 purchased from Inner Mongolia Kaidu New Material Technology Co., Ltd. The degree of alcoholysis of polyvinyl alcohol 2699 is 98%-100%, and the molecular weight is 107800-129800. The average degree of polymerization is 2450-2650.

[0078] In this example, the alkyl glycoside is APG0810.

[0079] The preparation method of the solid detergent not containing ethoxylate is as follows:

[0080] S1. Add 13kg of deionized water into a 150L stirring tank, stir at a speed of 120r / min,...

Embodiment 2

[0087] A solid detergent without ethoxylates, comprising the following components in parts by mass:

[0088] Polyvinyl alcohol 25kg; Mono-C12-18-alkyl sulfate sodium salt 25kg; Alkyl glucoside 14kg; Deionized water 12kg; Cocamidopropyl oxide 10kg; Cocamidopropyl betaine 8kg; Extract 5kg; silicon dioxide 5kg; glycerin 5kg; sodium citrate 4kg; polyether modified silicone oil 4kg; citric acid 3kg.

[0089] In this example, the polyvinyl alcohol is polyvinyl alcohol of the type 2499 purchased from Shanghai Meimengjia Chemical Technology Co., Ltd. The degree of alcoholysis of polyvinyl alcohol 2499 is 55%-65%, the molecular weight is 101200-110000, and the average The degree of polymerization is 2300-2500.

[0090] In this example, the alkyl glycoside is APG1214.

[0091] The preparation method of the solid detergent not containing ethoxylate is as follows:

[0092] S1. Add 12kg of deionized water into a 150L stirring tank, stir at a speed of 120r / min, slowly add 25kg of polyvin...

Embodiment 3

[0099] A solid detergent without ethoxylates, comprising the following components in parts by mass:

[0100] Deionized water 76kg; Mono-C12-18-alkyl sulfate sodium salt 20kg; Polyvinyl alcohol 5kg; Cocamidopropyl betaine 4kg; Cocamidopropyl oxide 3kg; 3kg of silicone oil; 2kg of sodium citrate; 2kg of glycerin; 1kg of alkyl glycoside; 0.5kg of Sapinberry extract;

[0101] In this example, polyvinyl alcohol is polyvinyl alcohol BP-26 purchased from Guangzhou Shuangpu Trading Co., Ltd., the degree of alcoholysis of polyvinyl alcohol BP-26 is 86%-89%, the molecular weight is 124000-130000, the average The degree of polymerization is 2500-2650.

[0102] In this example, the alkyl glycoside is APG0814.

[0103] The preparation method of the solid detergent not containing ethoxylate is as follows:

[0104] S1. Add 76kg of deionized water into a 150L stirred tank, stir at a speed of 120r / min, slowly add 5kg of polyvinyl alcohol under stirring, heat up to 85°C, and keep the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com