Power level simulation control method and device of three-phase alternating current motor

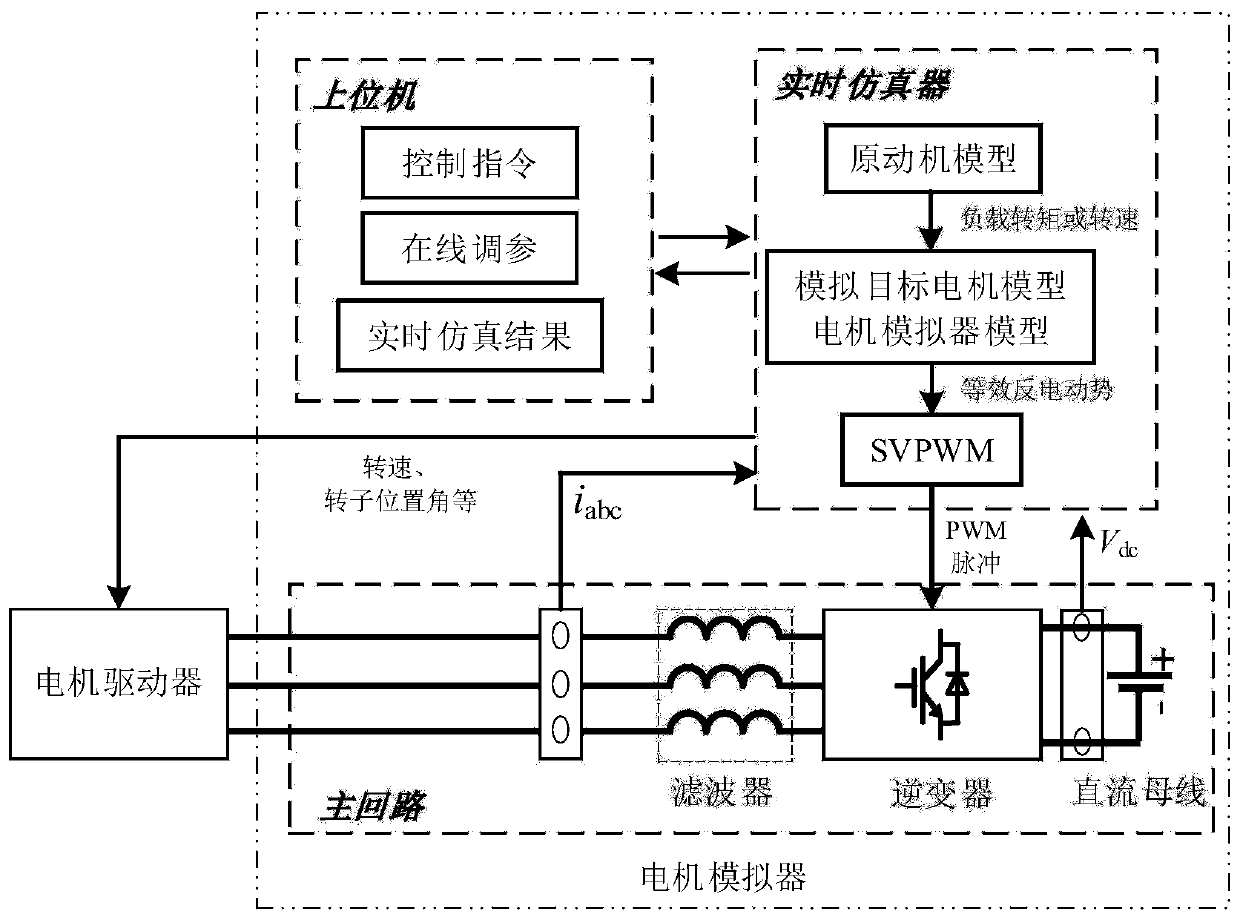

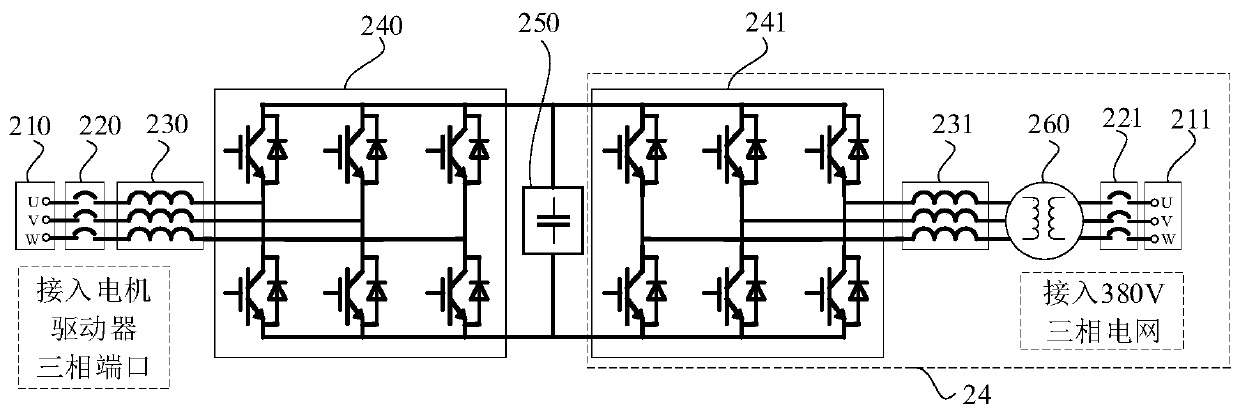

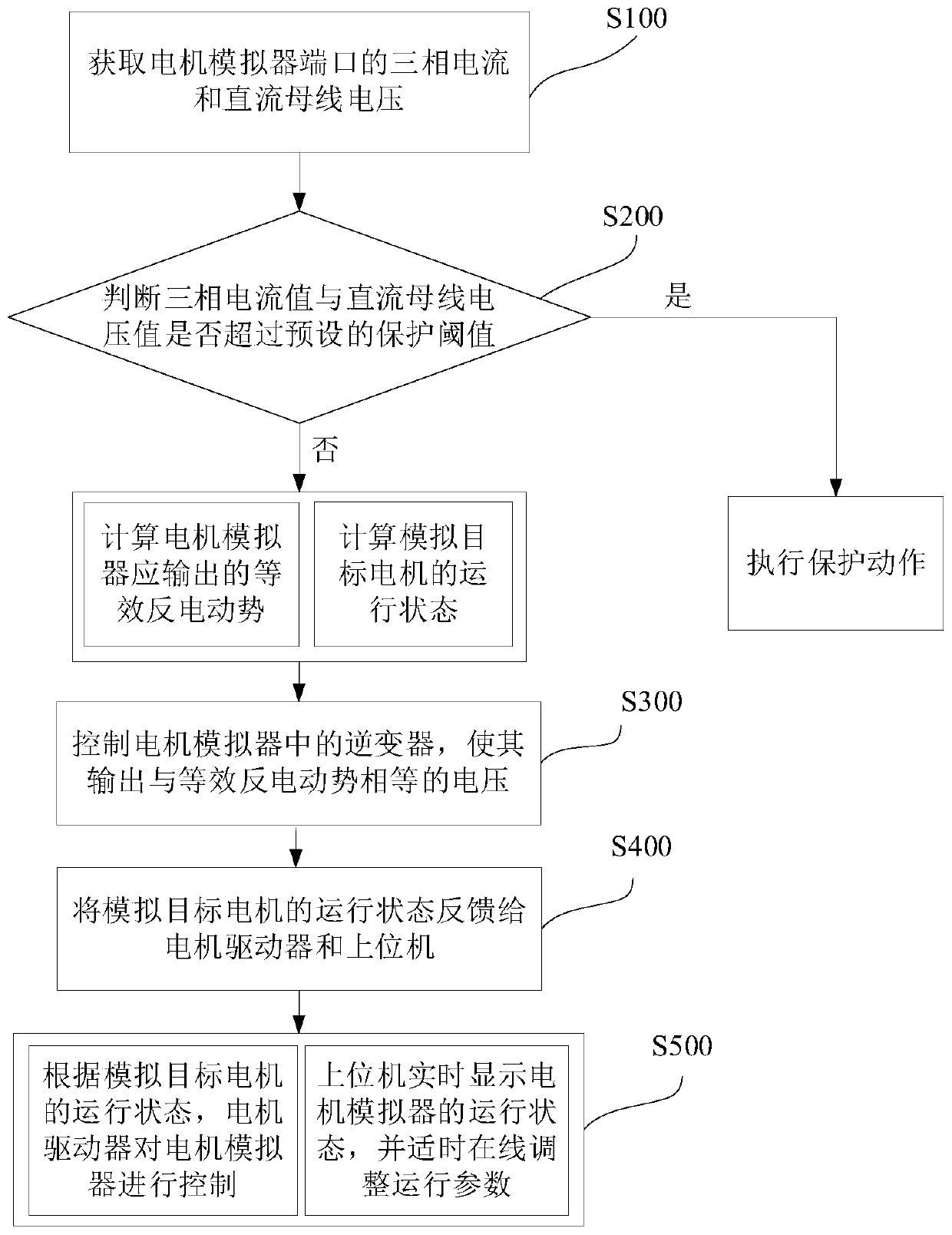

A motor simulation and three-phase AC technology, applied in simulators, general control systems, control/regulation systems, etc., can solve problems such as simulation errors and current feedback errors, and avoid FPGA programming and expensive high-performance computing chips Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Embodiment 1 Squirrel-cage asynchronous motor:

[0097] (3) formula becomes:

[0098]

[0099] where ψ rd is the rotor d-axis flux linkage; L m , L s , L r are the stator-rotor mutual inductance, stator self-inductance and rotor self-inductance respectively; σ is the flux leakage coefficient, and σ=1-L m 2 / (L s L r ). ψ rd It can be obtained by the flux observer. For example, take the following flux observer based on the current model:

[0100]

[0101] ψ in the formula rα with ψ rβ is the component of the rotor flux linkage along the α-axis and β-axis in the two-phase stationary coordinate system (that is, the αβ coordinate system), T r is the rotor time constant, ω e is the rotor electrical angular velocity. Observe that ψ rα with ψ rβ Afterwards, ψ is calculated by rd with θ:

[0102]

[0103] Meanwhile (4) becomes:

[0104]

[0105] With the help of (5), the rotor speed can be calculated.

Embodiment 2

[0106] Embodiment 2 permanent magnet synchronous motor:

[0107] (3) formula becomes:

[0108]

[0109] where ψ f is the flux linkage generated by the permanent magnet; L d , L q are the d-axis inductance and q-axis inductance of the motor, respectively.

[0110] (4) becomes:

[0111] T e =1.5n p [(L d -L q )i sd i sq + i sq ψ f ] (11)

[0112] With the help of (5), the rotor speed can be calculated, and the θ required for dq transformation can be obtained by integrating the speed.

Embodiment 3

[0113] Embodiment 3 Electric excitation synchronous motor:

[0114] (3) formula becomes:

[0115]

[0116] In the formula, L d , L q are the d-axis inductance and q-axis inductance of the motor, m af is the exciting inductance, i f is the excitation current.

[0117] (4) becomes

[0118] T e =1.5n p [(L d -L q )i sd i sq + i sq m af i f ] (13)

[0119] With the help of (5), the rotor speed can be calculated, and the θ required for dq transformation can be obtained by integrating the speed.

[0120] Compared with the expression in the embodiment of the permanent magnet synchronous motor, the expression in the embodiment of the electric excitation synchronous motor is only the rotor d-axis flux linkage ψ f change to m af i f , that is, the rotor flux linkage produced by the permanent magnets is transformed into that produced by the excitation current.

[0121] It is important to note that since there is no limit to L d , L q The value of , this simulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com