Method for preparing potassium titanate

A technology of potassium titanate and titanium precursors, applied in the direction of titanate, alkali metal titanate, chemical instruments and methods, etc., can solve problems such as high production costs, achieve cost saving, reduce reaction time and reaction temperature, The effect of improving economic efficiency and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

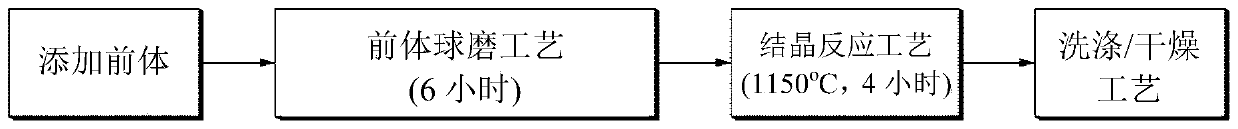

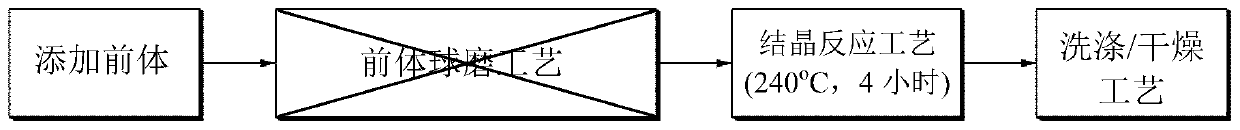

[0041] In the following, reference will be made to figure 2 The flow chart shown in describes in detail the various steps of the preparation method of potassium titanate according to one embodiment of the present invention.

[0042] step 1)

[0043] Step 1) according to one embodiment of the present invention is characterized in that a mixed solution comprising a titanium precursor and a potassium precursor is prepared.

[0044]The present invention is characterized in that potassium titanate is produced by producing high-purity nano-sized potassium titanate excellent in economic efficiency and productivity using a hydrothermal method.

[0045] Specifically, the hydrothermal method of the present invention is a method for synthesizing potassium titanate by utilizing the nucleation of precursors and the growth of crystals under supercritical conditions, wherein the reaction rate is fast at low temperatures, the dispersibility of particles is good, and the particle size , s...

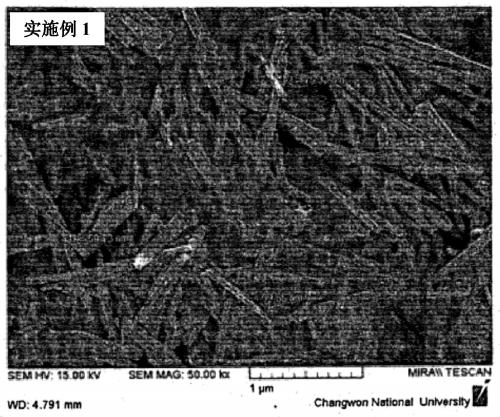

Embodiment 1

[0072] 1) The anatase phase TiO 2(Titanium(IV) oxide, anatase, 99.8%, SIGMA-ALDRICH) and potassium hydroxide (KOH, 85%, DEAJUNG) were mixed in distilled water (D.I water) at a molar ratio of 1:600 and stirred, 2) Heat treatment at 240° C. for 4 hours, and 3) washing and drying to prepare potassium titanate whiskers.

Embodiment 2

[0074] 1) The anatase phase TiO 2 and KOH were mixed in distilled water (D.I water) at a molar ratio of 1:600 and stirred, 2) heat-treated at 210° C. for 4 hours, and 3) washed and dried to prepare potassium titanate whiskers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com