Internal combustion steam engine

一种蒸汽机、燃烧室的技术,应用在内燃活塞发动机、燃烧发动机、机械设备等方向,达到降低风险、降低热应力、整体冷却简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The following description illustrates some embodiments and variants of the ICSE and the method of operation of the ICSE according to the present invention. The following description is not intended to limit the scope of the appended claims, but to illustrate some presently preferred embodiments of the invention.

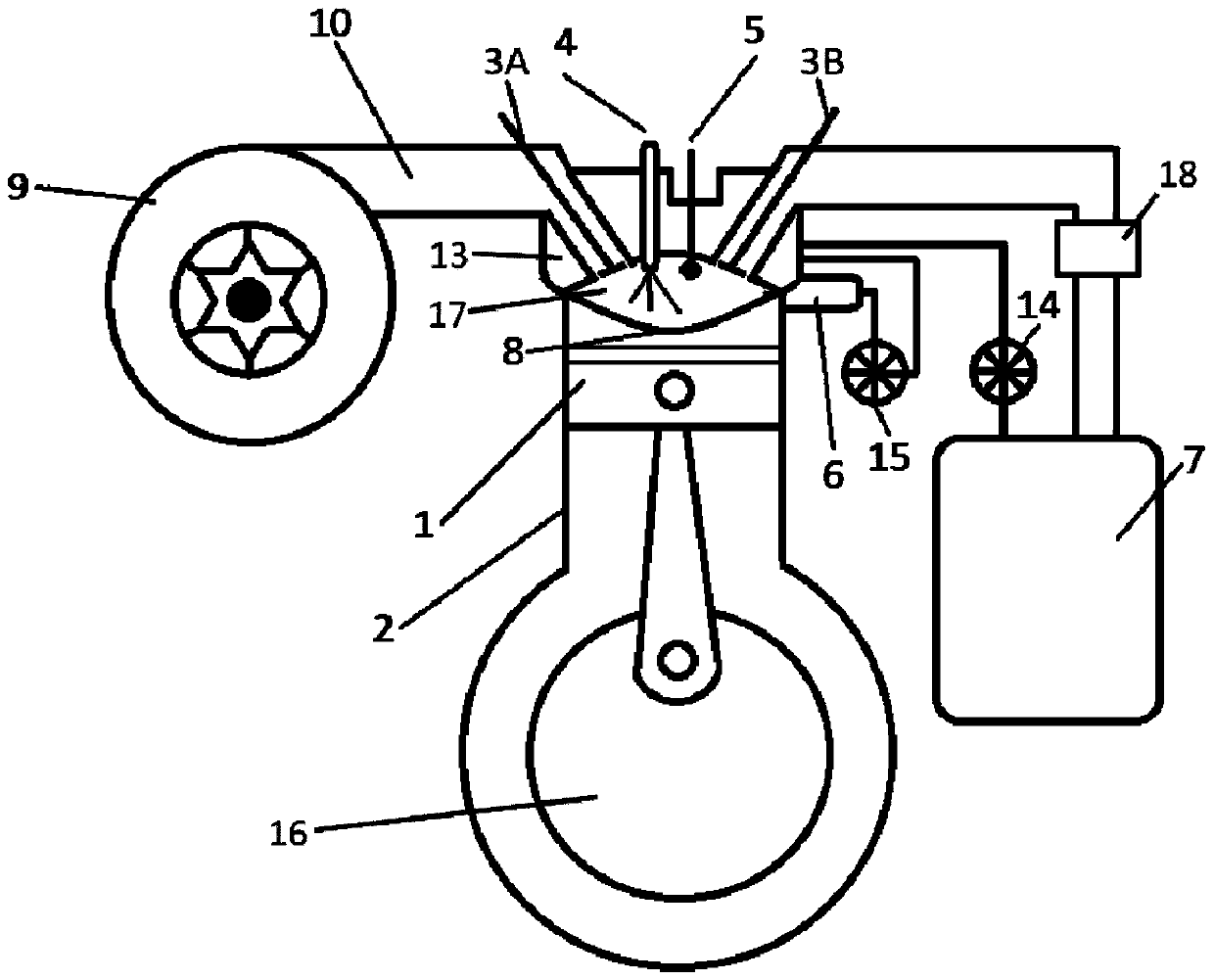

[0072] as well figure 1 and Figure 4 As shown, the internal combustion steam engine (ICSE) itself consists of a number of components similar to those known in internal combustion engines. An internal combustion steam engine has an engine casing, preferably made of a uniquely designed cylinder head, a somewhat standard cylinder block, and one or more pistons 1 mounted to a crankshaft 16 to achieve Change the reciprocating motion of the piston 1 into the rotational motion of the crankshaft 16.

[0073] While a standard gasoline engine has four strokes, namely: 1) the intake stroke, which uses the downward movement of the piston to draw air into the engine th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com