An arc plasma reactor and a method for lightening heavy oil

An arc plasma and plasma technology is applied in the field of plasma reactor and heavy oil conversion, which can solve the problems that the reaction cannot be effectively controlled, affect the plasma discharge, and affect the operation of the device, so as to reduce the coking reaction of heavy oil, increase the processing area, The effect of improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

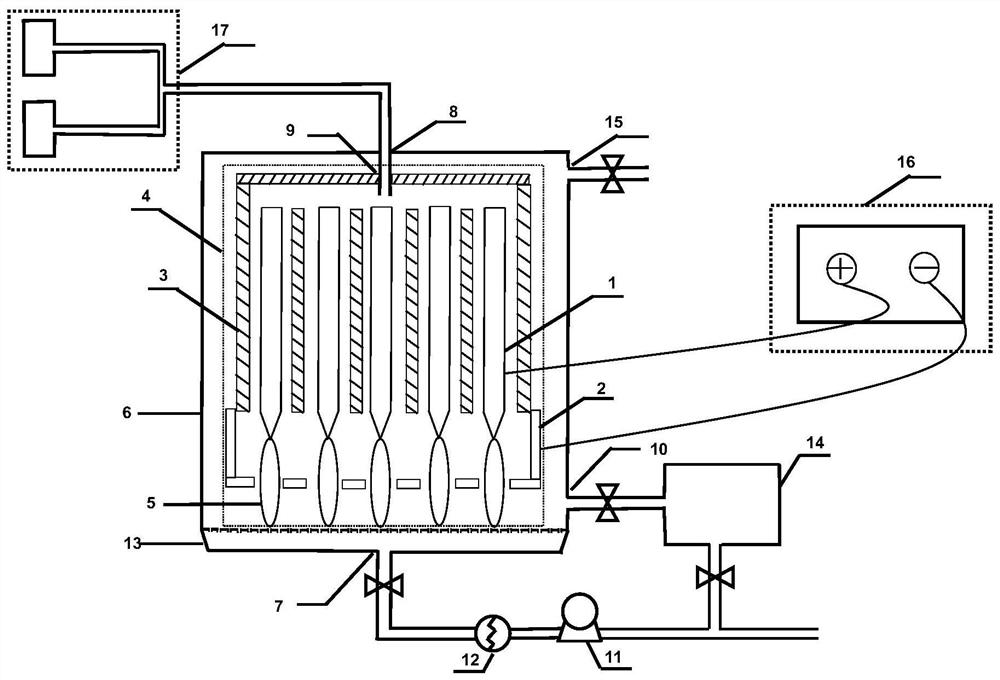

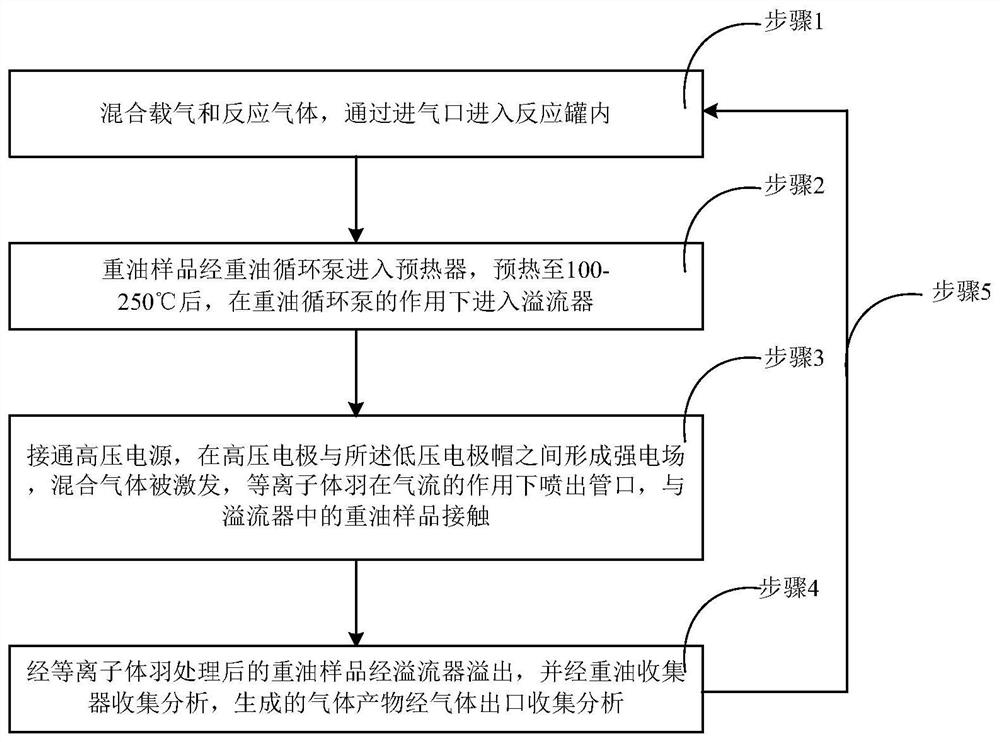

[0044] like figure 1 As shown, the arc plasma used in this embodiment includes a reaction tank 6 and a plasma array 4 located inside the reaction tank 6. A tank gas inlet 8 is provided above the reaction tank 6, and two gas paths of a carrier gas and a reaction gas are connected. The gas outlet 15 is arranged on the upper part of the side of the reaction tank 6, and the liquid product outlet 10 is arranged below the side wall of the reaction tank 6, and the liquid product outlet 10 is connected with the material collector 14 through a pipeline and a valve, and a reaction tank is provided at the bottom of the reaction tank. The bottom of the reaction tank 6 is provided with an overflow device 13, and the heavy oil pumped out from the raw material pump 11 can be preheated to the reaction temperature through the preheater 12 and enter the reaction through the reactant inlet 7 through the overflow device 13. Inside the tank, it is in contact with the plasma plume 5 generated by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com