Medium and low temperature combination processing method of coal tar

A low-temperature coal tar and combined processing technology, applied in the field of coal chemical industry, can solve the problems of short operation period, no utilization rate of coking heavy distillate oil, etc., and achieve the effects of avoiding cracking reaction, low product yield and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

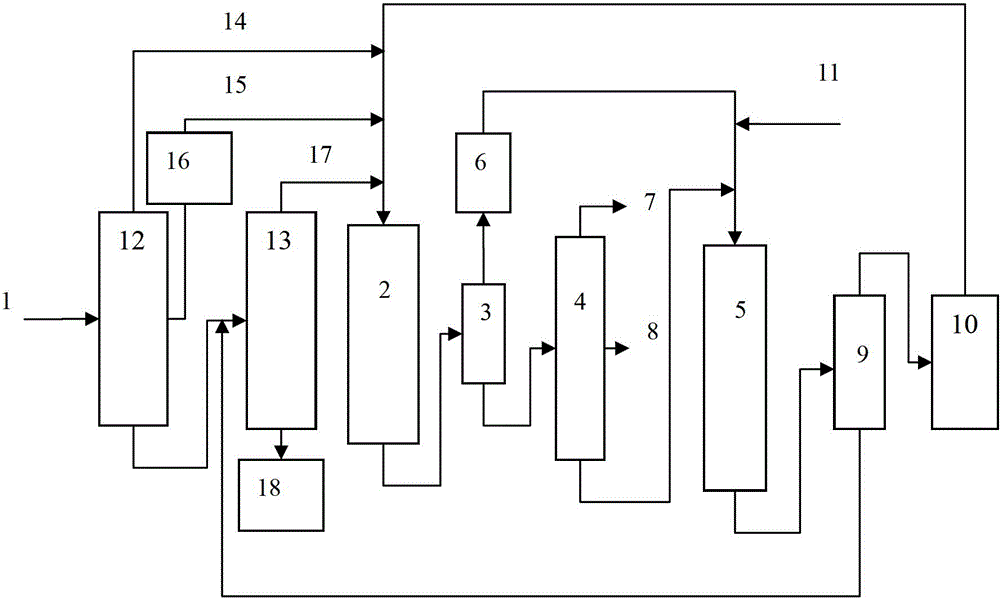

Image

Examples

Embodiment 1

[0075]The low-temperature dry distillation coal tar of Yilan lignite, whose properties are shown in Table 1, is sent to the pretreatment unit to remove mechanical impurities and water, and then subjected to atmospheric distillation to obtain light distillate oil, phenol oil and bottom oil, and the end point of light distillate oil The temperature is 180°C, the phenol oil is dephenolized to obtain dephenolized oil, the bottom oil and the liquid phase of the hydrocracking heat high-pressure separator enter the vacuum distillation tower, and the bottom of the vacuum distillation tower obtains asphalt residue, after deasphalting The heavy distillate oil (final boiling point is 580°C), as well as the light distillate oil and dephenolized oil obtained by atmospheric distillation enter the hydrotreating unit for hydrotreating reaction, and the gasoline fraction and diesel fraction obtained from the hydrotreating reaction can be out of the unit, and the heavy distillate oil obtained fr...

Embodiment 2

[0077] The hydrotreating catalyst (by weight of oxides) was prepared with the following composition: Mo, 30.0%; W, 8.0%; Ni, 2.5%; Co, 2.0%.

[0078] The solution containing the active components is a solution containing ammonium metatungstate, ammonium molybdate, nickel nitrate, and cobalt nitrate; the peptizer is nitric acid, the extrusion aid is azurite powder, and the pore expander is carbon black.

[0079] (1) Preparation of silicon-containing aluminum hydroxide. Prepare solid sodium aluminate to a concentration of 200gAl 2 o 3 / L concentrated sodium aluminate solution, then diluted to a concentration of 25gAl 2 o 3 / L sodium aluminate working solution, first add 10L containing 25gAl to the gel forming tank 2 o 3 / L sodium aluminate working solution, while passing air and passing CO with a concentration of 45v% 2 Gas, the reaction temperature is 25°C, the reaction time is 1 hour, and when the pH value reaches 12.0, add alkaline silicon-containing materials according...

Embodiment 3

[0084] The reaction temperature in the hydrotreating section is 350°C, and the liquid hourly volume space velocity is 1.0h -1 ;The reaction temperature of hydrocracking is 378℃, and the liquid hourly volume space velocity is 0.5h -1 . Before the hydrotreatment section, a hydrogenation protecting agent is used for pretreatment. The hydrogenation protecting agent is a conventional hydrogenation protecting agent, with alumina as the carrier, containing 6% molybdenum oxide, 1% cobalt oxide, and a pore volume of 0.82mL / g. The specific surface area is 128M 2 / g. The treatment conditions of the hydrogenation protective agent are reaction temperature 310°C, pressure 15.1MPa, hydrogen oil volume ratio 1200:1 and liquid hourly volume space velocity 1.2h -1 . Others are identical with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com