Dynamic pressure supporting device and method for thin-wall part processing

A thin-walled part processing and supporting device technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem of expensive equipment, and achieve the effects of improving surface quality, strong vibration absorption, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

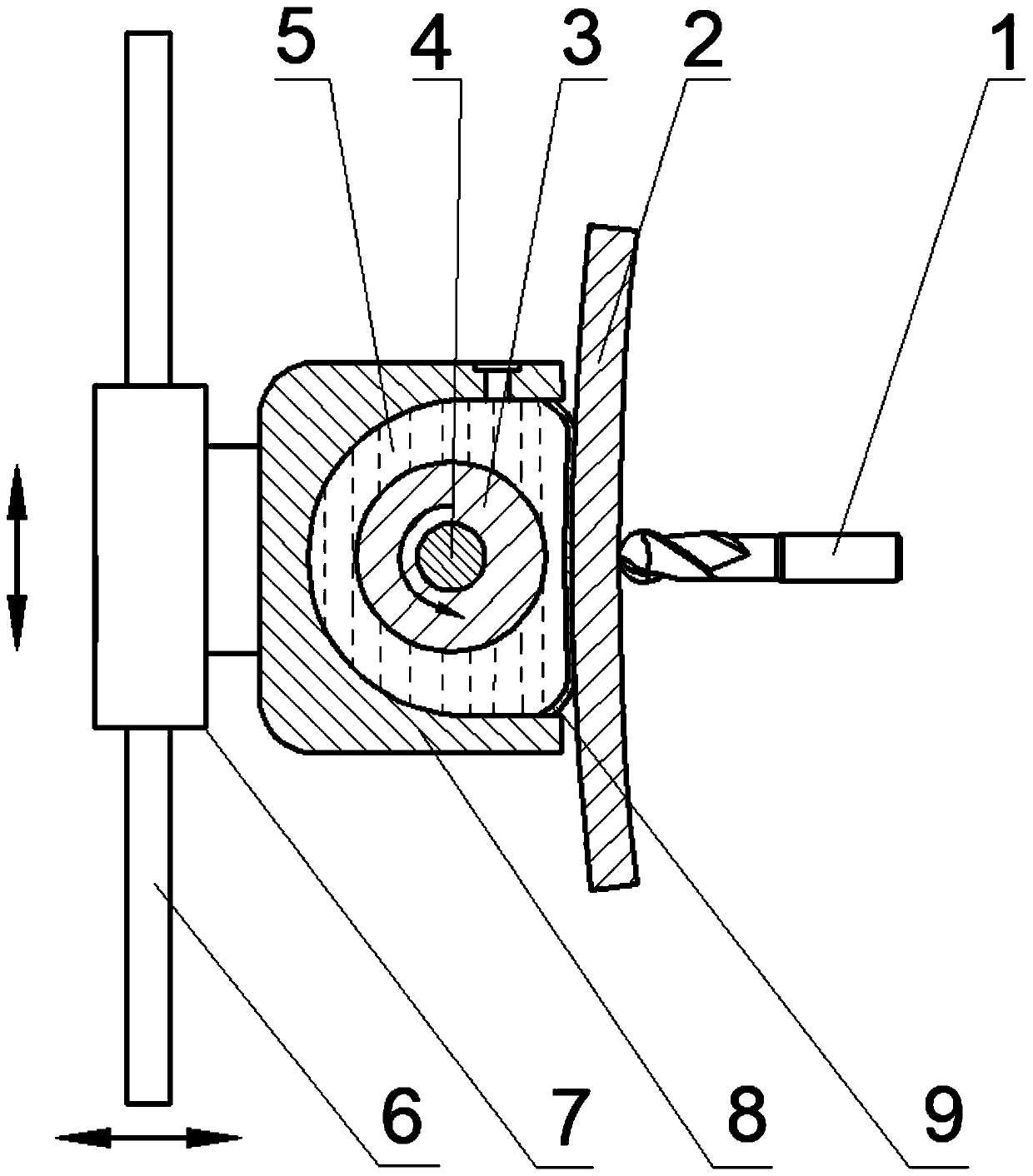

[0023] The processing system includes a tool 1, a workpiece 2 and a servo feed system. The tool 1 is used for milling a workpiece 2; the workpiece 2 is a material to be processed.

[0024] The dynamic pressure system includes a roller 3 , a shaft 4 , lubricating oil 5 , a guide rail 6 , a slide table 7 , an oil supply groove 8 and a flexible membrane 9 . There is a wedge-shaped gap between the roller 3 and the workpiece 2 . The shaft 4 drives the roller 3 to rotate through the motor, the roller 3 is immersed in the lubricating oil 5, the roller 3 rotates at a certain speed, and forms a relative motion with the surface of the workpiece 2 . Under the control of the servo feed system, the oil supply tank 8 can drive the oil supply tank 8 to move in the three directions of X, Y and Z. The lubricating oil 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com