Transfer container for nuclear reactor main cooling agent pump mechanical seals

A technology of mechanical seals and main coolant, applied in the direction of machine containers, containers, rigid containers, etc., can solve the problems of narrow space in the maintenance work area of mechanical seals, large exposure doses to operators, and impact on equipment assembly quality, etc., to reduce Generation of radioactive waste, reduction of risk of entry of foreign matter, effect of reduction of radioactive waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

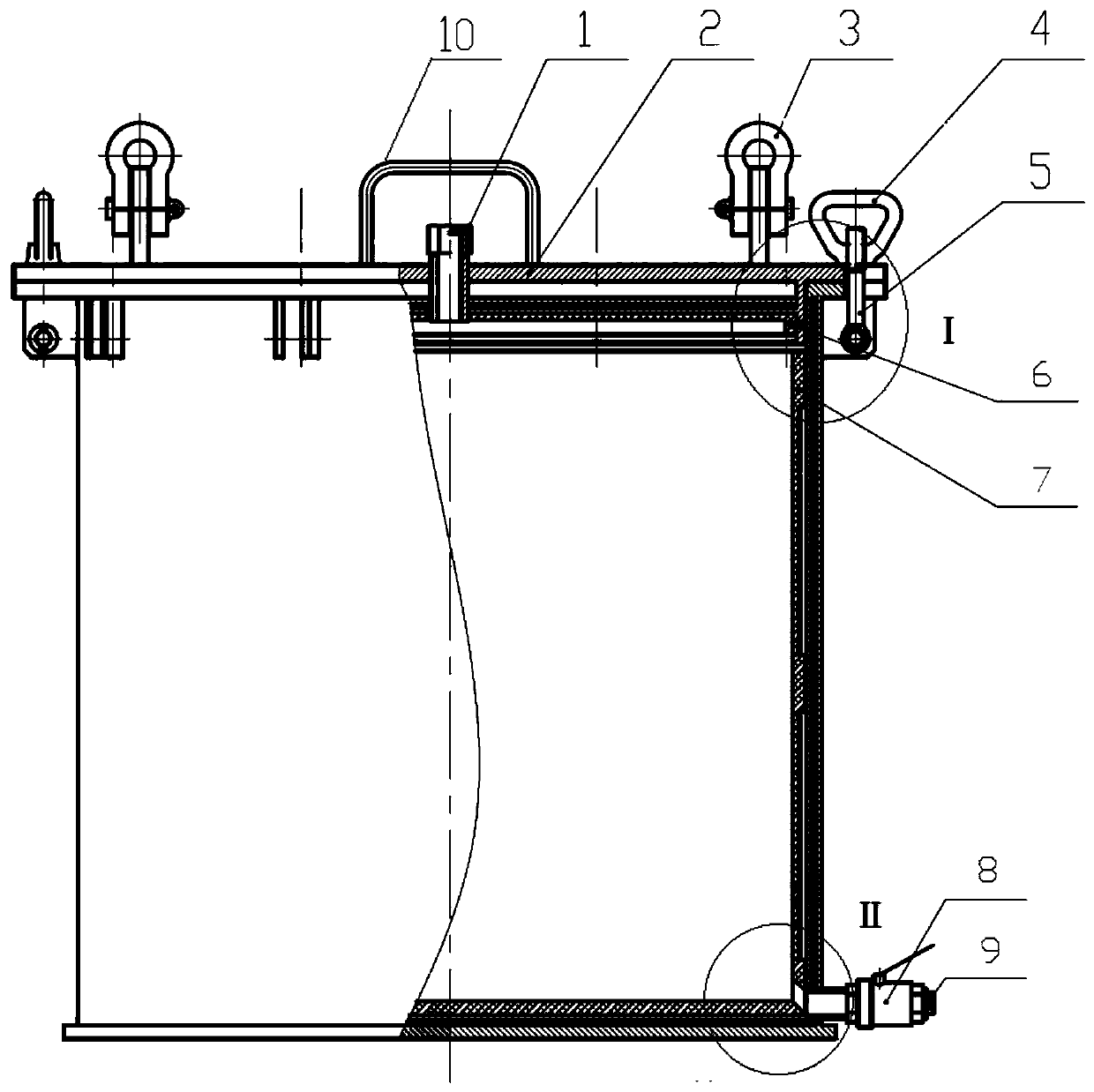

[0042] The transfer container for the mechanical seal of a nuclear reactor main coolant pump according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

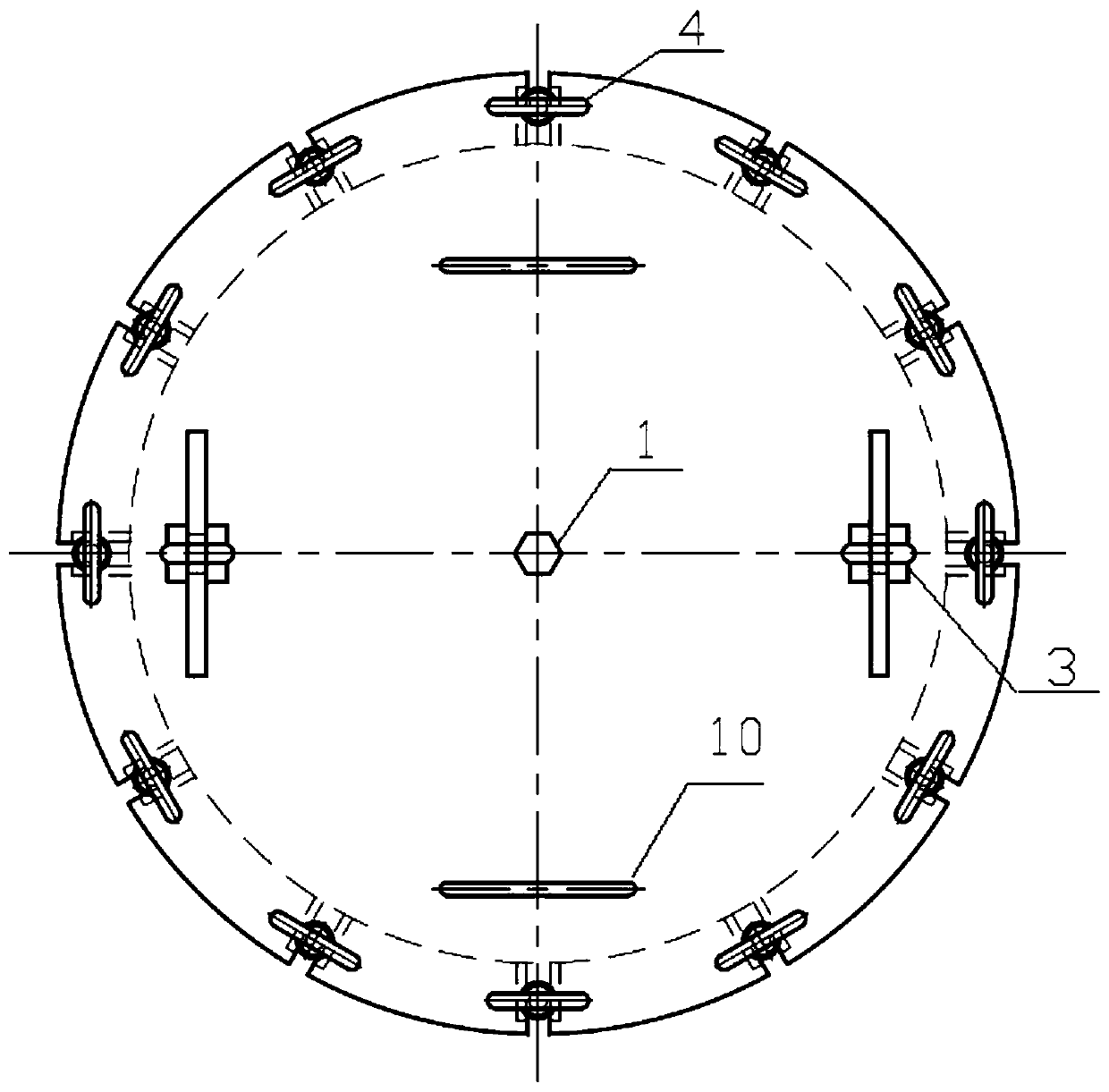

[0043] Such as Figure 1-3 As shown, a mechanically sealed transfer container for the main coolant pump of a nuclear reactor includes a barrel body, a barrel liner 7, a drain ball valve 8, a barrel cover 2, a ring nut 4, a union bolt 5, a shackle 3 and a handle 10;

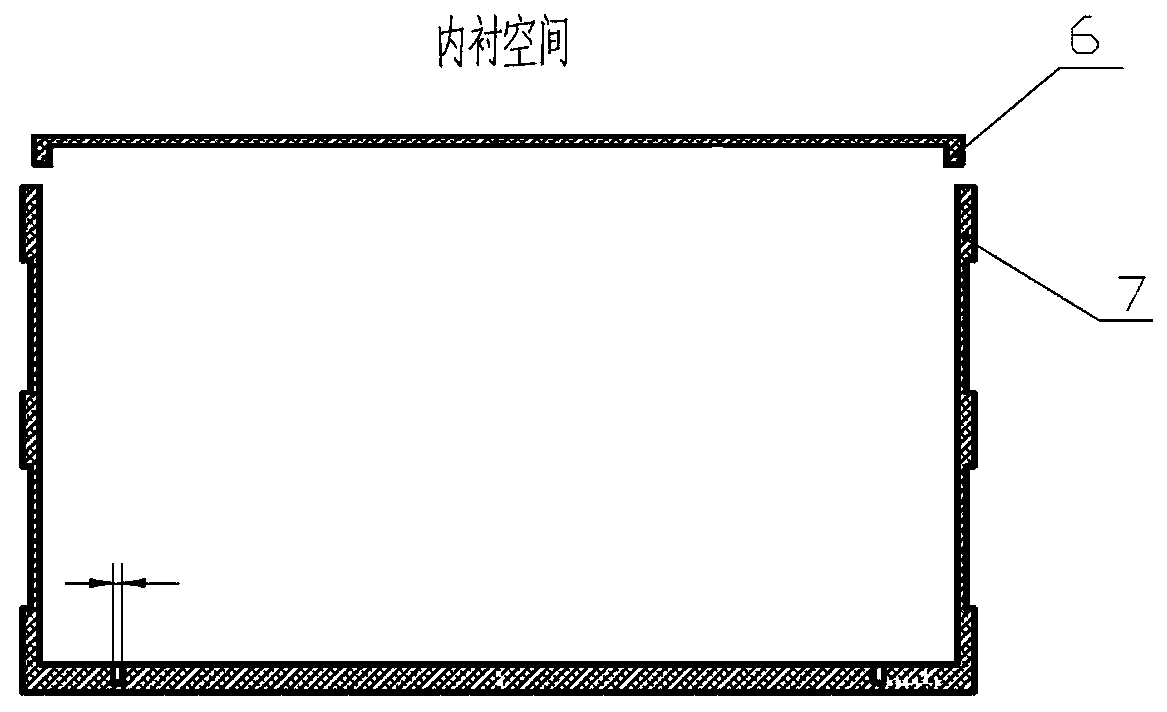

[0044] The barrel body is divided into three layers from the outside to the inside, wherein the first and third layers are made of welded stainless steel plates, and the second layer is a lead plate interlayer; a barrel liner 7 is inlaid inside the barrel body;

[0045] There are 12 evenly distributed joint bolt installation plates on the outer side of the upper part of the barrel, and joint bolts 5 are installed on the joint joint installation plates of the barrel body, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com