A kind of steel slag modification method

A steel slag and modification technology, which is applied in the field of industrial solid waste resource utilization and environmental protection engineering, can solve the problems of low stability and activity, and achieve the effects of reducing production costs, less environmental pollution, and reducing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

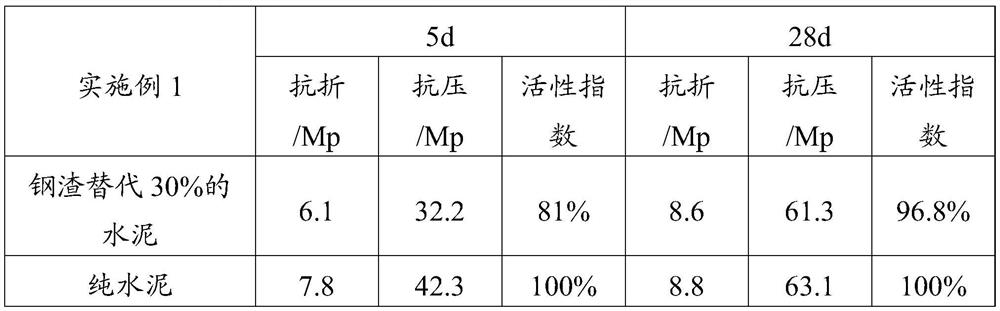

Embodiment 1

[0026] Get the high-temperature converter steel slag that steelmaking plant produces and place in the slag tank, add 0.5% boron modifier (B in the boron modifier) wherein 2 o 3 account for more than 0.8%), when it cools to about 600°C, spray water into the slag tank to seal it, the waste heat of steel slag turns the water in the slag tank into steam, and the steam discharge pipe installed on the slag tank adjusts the water in the slag tank The steam pressure is about 0.2MPa. The thermal stress generated by the steel slag’s own heat cracks the large steel slag, and at the same time, a large amount of saturated steam penetrates into the steel slag, and interacts with the free calcium oxide f-CaO and free magnesium oxide f-MgO in the steel slag to generate volume expansion stress, so that the steel slag is further powdered The entire slag stewing time is 12 hours, and the particle size of steel slag after pulverization is less than 10mm.

[0027] Mix the pulverized steel slag...

Embodiment 2

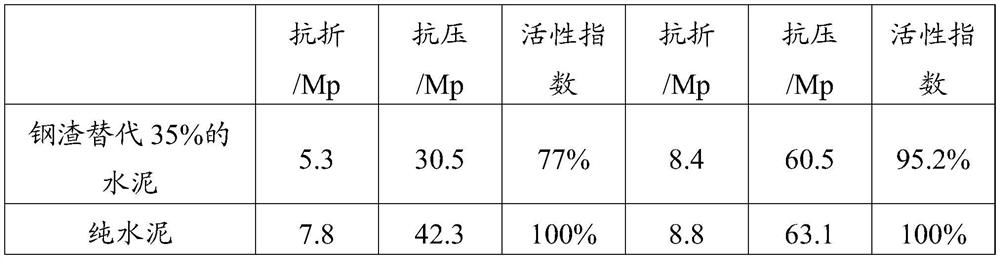

[0036] Take the high-temperature converter steel slag produced in the steelmaking plant and place it in the slag tank, add 3% boron modifier to it, and when it cools to about 800°C, spray water into the slag tank to seal it, and the waste heat of the steel slag will burn the inside of the slag tank. The water in the slag tank is turned into water vapor, and the steam pressure in the slag tank is adjusted to about 0.3MPa by the steam discharge pipe installed on the slag tank. The thermal stress generated by the steel slag’s own heat cracks the large steel slag, and at the same time, a large amount of saturated steam penetrates into the steel slag, and interacts with the free calcium oxide f-CaO and free magnesium oxide f-MgO in the steel slag to generate volume expansion stress, so that the steel slag is further powdered melting, the whole stewed slag time is 8 hours. The particle size of steel slag after pulverization is less than 10mm.

[0037] The pulverized steel slag is m...

Embodiment 3

[0045]Take the high-temperature converter steel slag produced in the steelmaking plant and place it in the slag tank, add 1% boron modifier to it, and when it cools to about 700°C, spray water into the slag tank to seal it, and the residual heat of the steel slag will burn the inside of the slag tank. The water in the slag tank is turned into water vapor, and the steam pressure in the slag tank is adjusted to about 0.3MPa by the steam discharge pipe installed on the slag tank. The thermal stress generated by the steel slag’s own heat cracks the large steel slag, and at the same time, a large amount of saturated steam penetrates into the steel slag, and interacts with the free calcium oxide f-CaO and free magnesium oxide f-MgO in the steel slag to generate volume expansion stress, so that the steel slag is further powdered melting, the whole stewed slag time is 10 hours. The particle size of steel slag after pulverization is less than 10mm.

[0046] The pulverized steel slag i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com