Antibacterial paint containing porous organisms and preparation method thereof

An antibacterial coating and organism technology, applied in the field of antibacterial coatings containing porous organisms and their preparation, can solve the problems of poor wear resistance of antibacterial coatings, uneven drug distribution, hindering drug efficacy, etc., and achieve strong wear resistance and reduce localization. Bacterial bloom problem, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

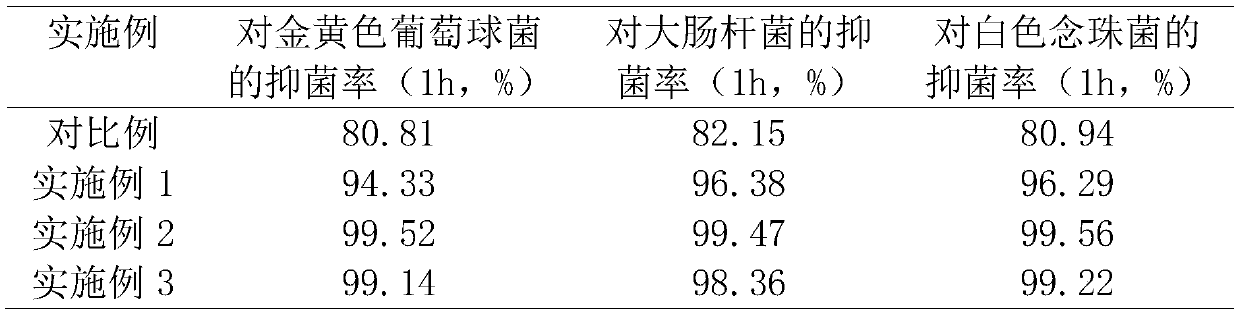

Examples

Embodiment 1

[0061] Embodiment 1: adopt method one to prepare the antibacterial coating that contains porous organism

[0062] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat and spheroidize the powder, add 20wt% absolute ethanol to the prepared powder, disperse at a high speed, and then classify with a tubular centrifuge 2- 3 times, finally get a powder with good dispersibility and dry it in a vacuum oven at 35-45°C for use;

[0063] 2) Take a certain amount of Ti(OH) 4 , using radio frequency induction plasma to prepare nano-titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse at high speed, then classify 2-3 times with a tubular centrifuge, and finally get a powder with good dispersibility at 35- Dry in a vacuum oven at 45°C for use;

[0064] 3) Preparation of porous organic powder: cleaning, drying, crushing and other processes of wheat husks to make micron-sized organic p...

Embodiment 2

[0073] Embodiment 2: adopt method two to prepare the antibacterial coating that contains porous organism

[0074] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat and spheroidize the powder, add 20wt% absolute ethanol to the prepared powder, disperse at a high speed, and then classify with a tubular centrifuge 2- 3 times, finally get a powder with good dispersibility and dry it in a vacuum oven at 35-45°C for use;

[0075] 2) Take a certain amount of TiO(OH) 2 , using radio frequency induction plasma to prepare nano-titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse at high speed, then classify 2-3 times with a tubular centrifuge, and finally get a powder with good dispersibility at 35- Dry in a vacuum oven at 45°C for use;

[0076] 3) Preparation of porous organism powder: washing, drying, crushing and other processes of bean stalks to make micron-sized organism...

Embodiment 3

[0085] Embodiment 3: adopt method three to prepare the antibacterial coating that contains porous organism

[0086] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat and spheroidize the powder, add 20wt% absolute ethanol to the prepared powder, disperse at a high speed, and then classify with a tubular centrifuge 2- 3 times, finally get a powder with good dispersibility and dry it in a vacuum oven at 35-45°C for use;

[0087] 2) Take a certain amount of TiO 2 , using radio frequency induction plasma to prepare nano-titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse at high speed, then classify 2-3 times with a tubular centrifuge, and finally get a powder with good dispersibility at 35- Dry in a vacuum oven at 45°C for use;

[0088] 3) Preparation of porous organic powder: washing, drying, crushing and other processes of cotton stalks to make micron-sized organic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com