Composite anti-fog lens and preparation method thereof

A lens and anti-fog technology, applied in coatings, instruments, optics, etc., can solve the problems of poor durability and friction resistance, interference with the vision of the wearer of glasses, fogging, etc., to achieve good durability, not easy to be thermally decomposed, and effective quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

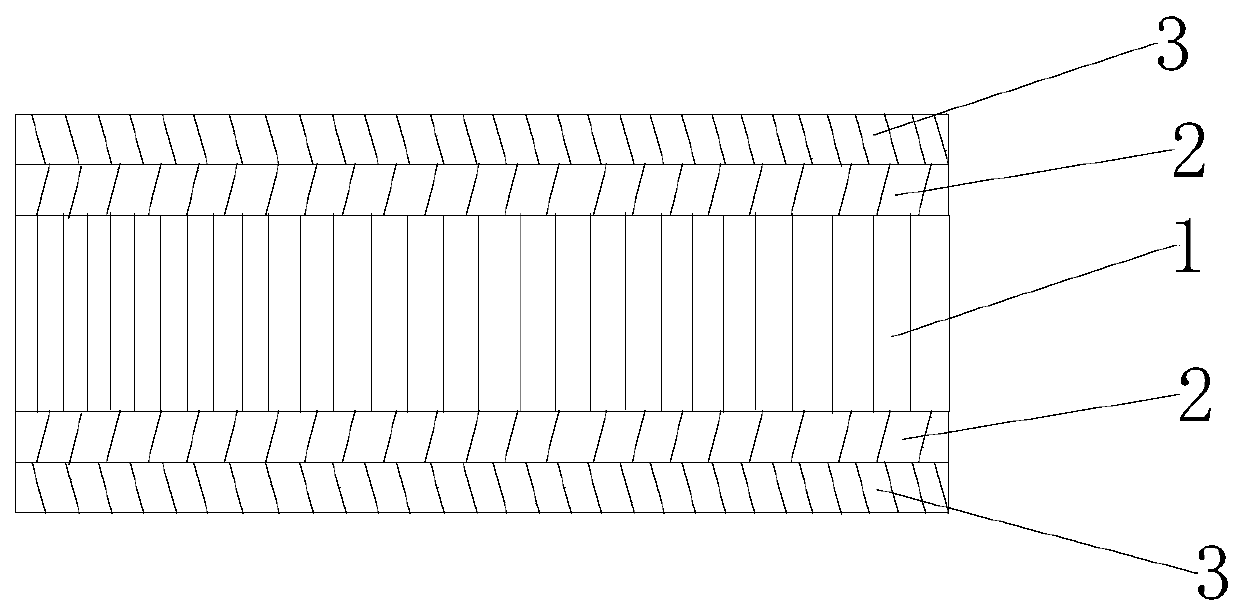

[0032] refer to figure 1 , a composite anti-fog lens, comprising a base material 1, the base material 1 is a glass lens or a resin lens, the outer surface of the base material 1 is sequentially compounded with a base layer 2 and an upper anti-fog layer 3, the base layer 2 is prepared from aminosilane and organosilylamine by dipping-pulling technology; the upper anti-fog layer 3 is mainly prepared from vinyl alcohol polymer, acrylic polymer and organosilane by dipping-pulling technology. The organosilane is preferably aminosilane; the present invention solidifies a layer of self-assembled organosilane and organosilyl amine composite macromolecule on the upper and lower surfaces of the substrate, which can improve the timeliness and wear resistance of the anti-fog film. The uniformity of the film prepared by dipping method is better.

[0033] The structural formula of described aminosilane is: (R 1 O) 3 -Si-R 2 -NH 2 , where R 1 for C 1-2 the alkyl group, R 2 for C 1-4 ...

Embodiment 2

[0036] A preparation method of a composite anti-fog lens, comprising the steps of:

[0037](1) Preparation of base layer curing primer: 3-aminopropyltriethoxysilane and bis(3-trimethoxysilylpropyl)amine are mixed according to a volume ratio of 10:1 to obtain a mixed solution, and then The mixed solution is dropped into ethanol and stirred to obtain a clear and transparent base solution, wherein the volume fraction of the mixed solution in ethanol is 0.5%;

[0038] (2) Preparation of the upper anti-fog liquid: Pour polyvinyl alcohol into deionized water and stir, then add polyacrylic acid, and continue stirring to obtain a mixed solution of polyvinyl alcohol and polyacrylic acid; mix 3-aminopropyltriethoxysilane Drop into the mixed solution of polyvinyl alcohol and polyacrylic acid, stir to obtain a transparent upper layer anti-fog liquid; wherein the content of polyvinyl alcohol in the obtained upper layer anti-fog liquid is 1 mg / ml, and the content of polyacrylic acid is 1 mg...

Embodiment 3

[0045] A preparation method of a composite anti-fog lens, comprising the steps of:

[0046] (1) Preparation of base layer curing primer: 3-aminopropyltriethoxysilane and bis(3-trimethoxysilylpropyl)amine are mixed according to the volume ratio of 2:1 to obtain a mixed solution, and then The mixed solution is dropped into ethanol and stirred to obtain a clear and transparent base solution, wherein the volume fraction of the mixed solution in ethanol is 2%;

[0047] (2) Preparation of the upper anti-fog liquid: Pour polyvinyl alcohol into deionized water and stir, then add polyacrylic acid, and continue stirring to obtain a mixed solution of polyvinyl alcohol and polyacrylic acid; mix 3-aminopropyltriethoxysilane Drop into the mixed solution of polyvinyl alcohol and polyacrylic acid, stir to obtain a transparent upper layer anti-fog liquid; wherein the content of polyvinyl alcohol in the obtained upper layer anti-fog liquid is 10 mg / ml, and the content of polyacrylic acid is 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com