A kind of preparation method of magneto-optic optical fiber with high verdet constant

A technology of optical fiber preform and constant, which is applied in cladding optical fiber, optical waveguide light guide, optical, etc., can solve the problem of low nanometer deposition efficiency, and achieve the effect of excellent magneto-optical characteristics, easy production, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

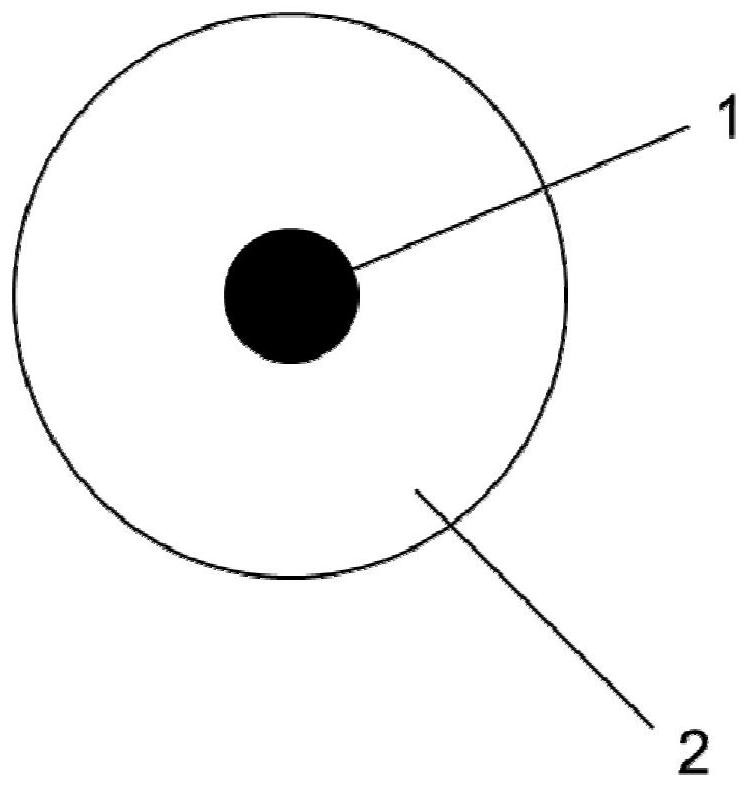

[0021] The specific embodiment of the present invention proposes a method for preparing a high Verdet constant magneto-optical optical fiber, which is used to prepare a terbium-doped silica fiber with a high Verdet constant. The optical fiber prepared by the preparation method has high doping concentration and uniformity. Good, excellent magneto-optical characteristics, good thermal stability, simple structure, easy production, etc., suitable for high-current sensors, optical isolators, nonlinear optics, magneto-optical switches, magneto-optical modulators, etc. The preparation method includes:

[0022] Deposition of GeO on the Inner Surface of Substrate Tube by Modified Chemical Vapor Deposition (MCVD) 2 and SiO 2 ; Utilize the high-temperature evaporation deposition method to uniformly deposit terbium oxide particles on the inner surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com