Yttria-stabilized terbia powder, magneto-optic transparent ceramic and preparation method of magneto-optic transparent ceramic

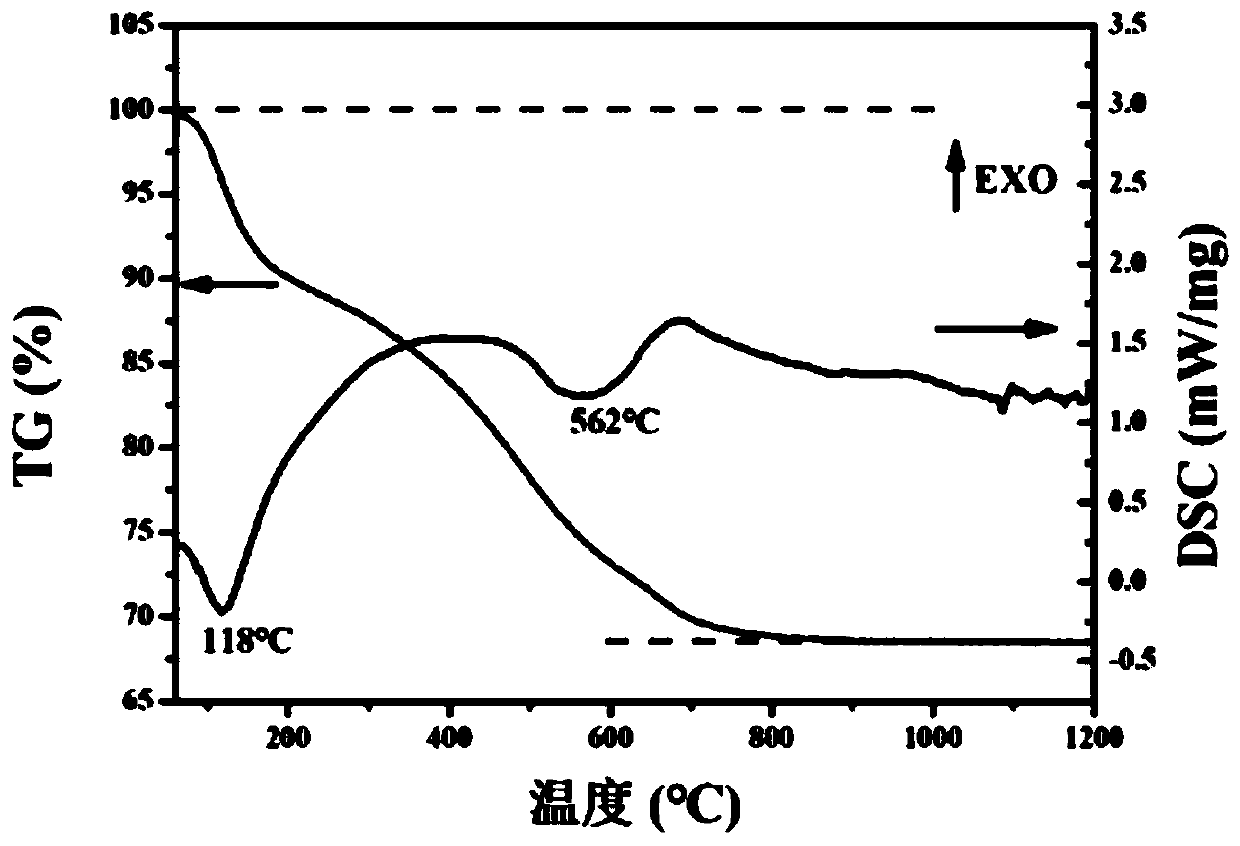

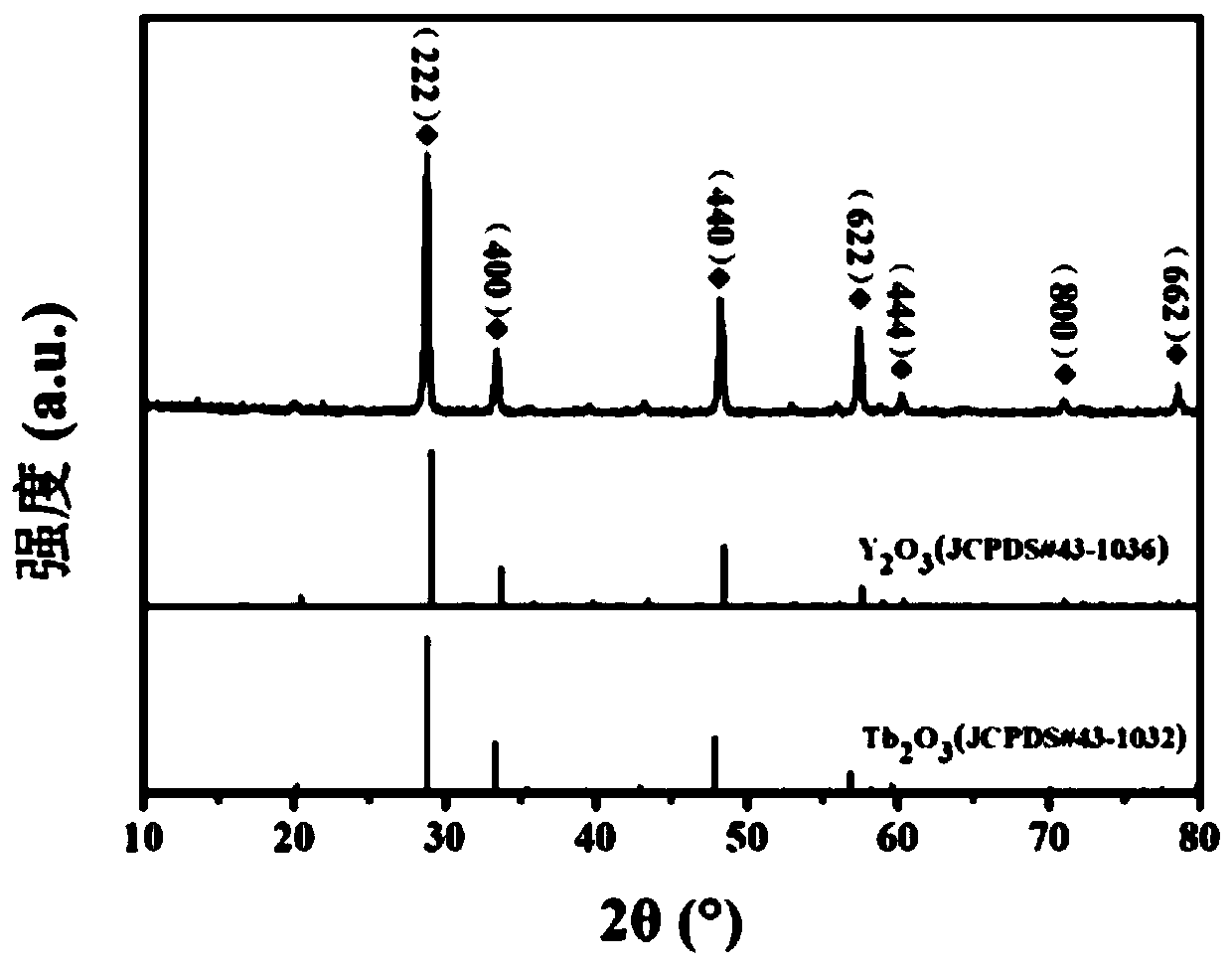

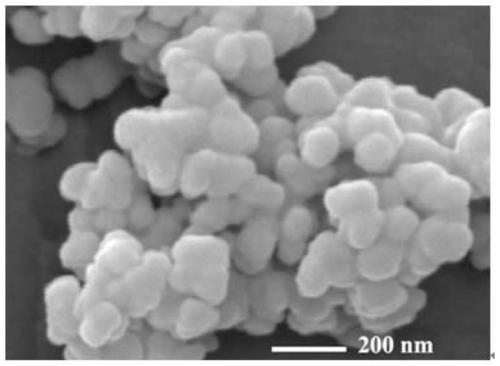

A technology of transparent ceramics and terbium oxide, which is applied to the preparation of 2O3 nano-powder by wet chemical co-precipitation method and the preparation of transparent ceramics by pure hydrogen pressureless sintering process, can solve the problem of no magneto-optical effect, difficult to make large size, affecting optical Transmittance and other issues, to achieve the effect of improved magneto-optical performance, stable valence and phase structure, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of yttrium stabilized terbium oxide magneto-optical transparent ceramics, the specific steps are:

[0046] Will Tb 2 o 3 , Y 2 o 3 Dissolve in the nitric acid solution that mass concentration is 68% respectively and react to obtain 0.15mol / L Tb(NO 3 ) 3 solution and 0.15mol / L of Y(NO 3 ) 3 solution;

[0047] Press (Tb 0.5 Y 0.5 ) 2 o 3 Chemical composition, measure Tb(NO 3 ) 3 Solution 150ml, concentration is 0.15mol / L Y(NO 3 ) 3 Solution 150ml, pour into a 500ml beaker and mix evenly to obtain a metal ion salt mixed solution;

[0048] Configure NH 4 HCO 3 and NH 4 OH mixed precipitant solution, in which, NH 4 HCO 3 The concentration is 2mol / L, NH 4 OH concentration is 2mol / L.

[0049] The precipitant solution was dropped into the metal ion salt mixed solution at a rate of 4ml / min and stirred thoroughly. Stop dripping until the pH value of the obtained solution is 7.2, continue to stir for 3 minutes and then stop stirring. Aft...

Embodiment 2

[0057] A preparation method of yttrium stabilized terbium oxide magneto-optical transparent ceramics, the specific steps are:

[0058] Will Tb 2 o 3 , Y 2 o 3 Dissolve in the nitric acid solution that mass concentration is 68% respectively and react to obtain 0.15mol / L Tb(NO 3 ) 3 solution and 0.15mol / L of Y(NO 3 ) 3 solution;

[0059] Press (Tb0.3 Y 0.7 ) 2 o 3 Chemical composition, measure Tb(NO 3 ) 3 Solution 90ml, concentration is 0.15mol / L Y(NO 3 ) 3 210ml of the solution was poured into a 500ml beaker and mixed evenly to obtain a metal ion salt mixed solution;

[0060] Configure NH 4 HCO 3 and NH 4 OH mixed precipitant solution, in which, NH 4 HCO 3 The concentration is 2mol / L, NH 4 OH concentration is 2mol / L.

[0061] The precipitant solution was dropped into the metal ion salt mixed solution at a rate of 4ml / min and stirred thoroughly. Stop dripping until the pH value of the obtained solution is 7.5, continue to stir for 3 minutes, and then stop s...

Embodiment 3

[0064] A preparation method of yttrium stabilized terbium oxide magneto-optical transparent ceramics, the specific steps are:

[0065] Will Tb 2 o 3 , Y 2 o 3 Dissolve in the nitric acid solution that mass concentration is 68% respectively and react to obtain 0.15mol / L Tb(NO 3 ) 3 solution and 0.15mol / L of Y(NO 3 ) 3 solution;

[0066] Press (Tb 0.5 Y 0.5 ) 2 o 3 Chemical composition, measure Tb(NO 3 ) 3 Solution 150ml, concentration is 0.15mol / L Y(NO 3 ) 3 Solution 150ml, pour into a 500ml beaker and mix evenly to obtain a metal ion salt mixed solution;

[0067] Configure NH 4 HCO 3 and NH 4 OH mixed precipitant solution, in which, NH 4 HCO 3 The concentration is 2mol / L, NH 4 OH concentration is 2mol / L.

[0068] The precipitant solution was dropped into the metal ion salt mixed solution at a rate of 4ml / min and stirred thoroughly. Stop dripping until the pH value of the obtained solution is 7.6, continue stirring for 3 minutes, then stop stirring. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com