Metal and carbon fiber reinforced resin matrix composite laminated plate holeless riveting device and method

A technology for reinforcing resin matrix and composite material layer, applied in the field of material processing, can solve the problems of small plasticity and large springback, and achieve the effects of improving plasticity, stable riveting quality and avoiding delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

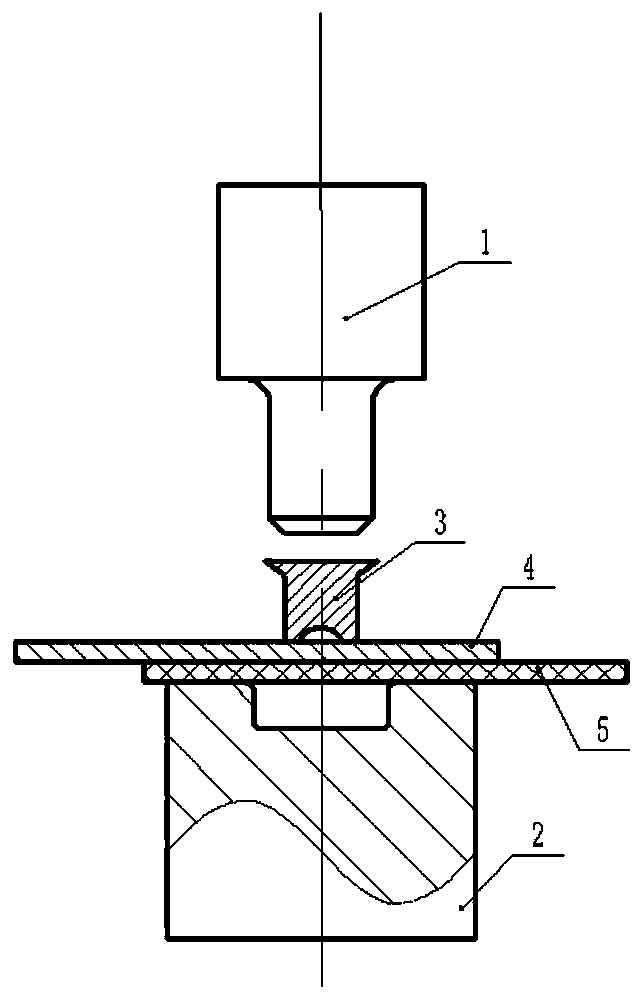

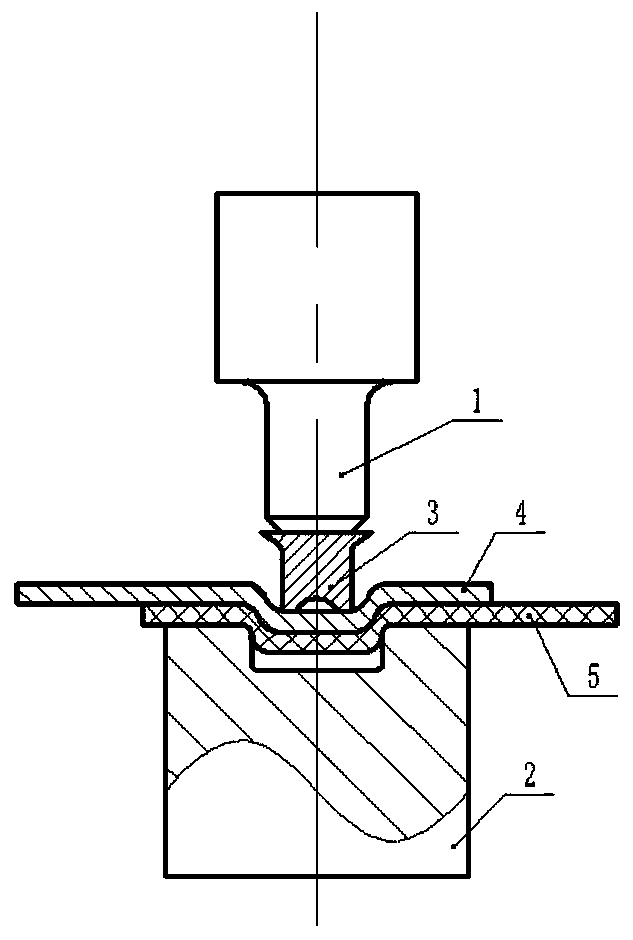

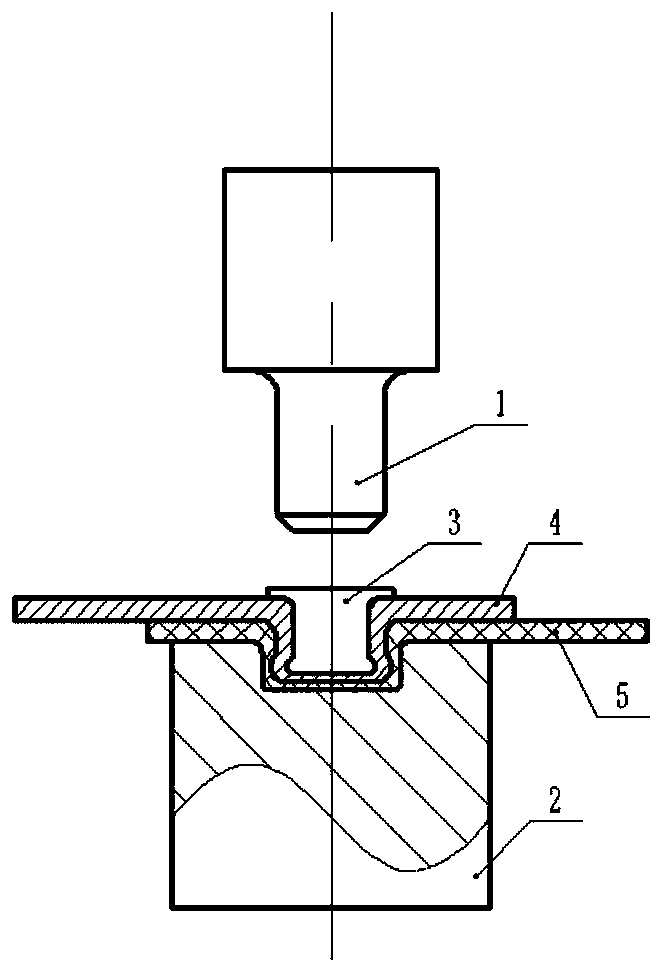

[0024] Such as figure 1 As shown, a non-porous riveting device for metal and carbon fiber reinforced resin matrix composite laminates, including a riveting punch 1, a riveting die 2 and a shallow pit rivet 3, the riveting punch 1 is a cylindrical punch, and the riveting die 2 The cavity is a cylindrical cavity, such as Figure 4 and 5 As shown, the shallow pit rivet 3 has a T-shaped structure, the horizontal section of the shallow pit rivet, that is, the nail cap 31, is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com