Quartz boat and method for using quartz boat to complete polycrystalline synthesis and single crystal growth of gallium selenide at one time

A quartz boat and quartz technology, applied in the field of crystal synthesis devices, can solve the problems of high cost and high single crystal impurities, and achieve the effects of simple operation, improved quality and excellent optical quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

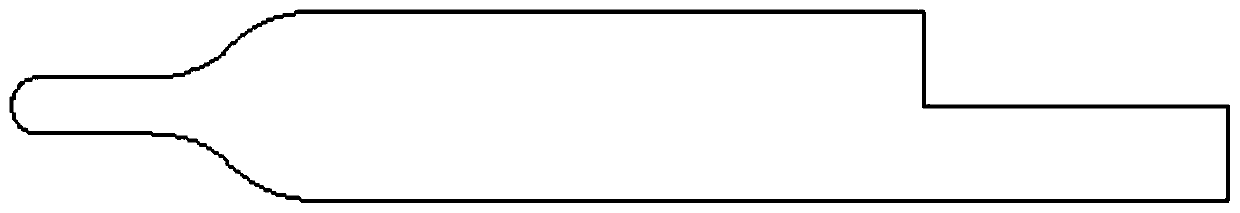

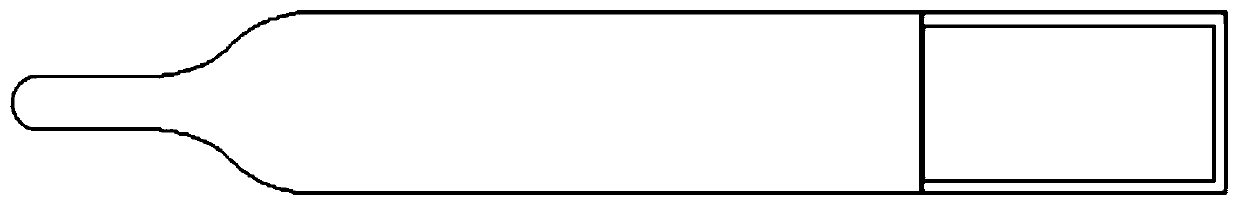

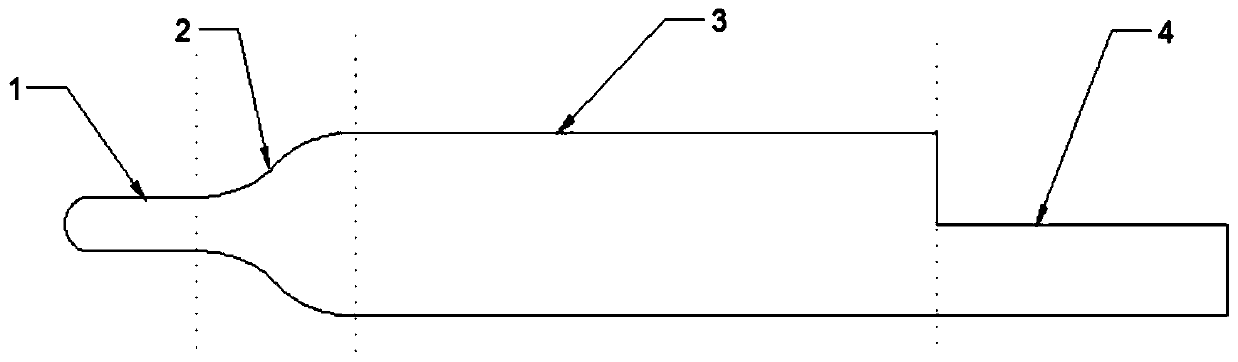

[0027] Embodiment 1: The quartz boat of this embodiment is composed of a seed crystal well area 1, a shoulder area 2, a closed area 3, and an open area 4; wherein the seed crystal well area 1 is cylindrical with one end sealed; the shoulder area 2 is frustum-shaped; closed area 3 is cylindrical; open area 4 is semi-cylindrical; seed crystal well area 1, shoulder area 2, closed area 3 and open area 4 are connected in sequence, and their axes are on the same straight line superior.

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the seed crystal well region 1 is connected to the shoulder region 2 by an arc, and the shoulder region 2 and the closed region 3 are connected by an arc; others are the same as Embodiment 1. same.

[0029] The setting of this embodiment is beneficial to the continuous and stable growth of single crystal in the single crystal growth stage.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the ratio of the diameters of the seed crystal well region 1 to the closed region 3 is 1: (5-8); others are the same as Embodiment 1 or Embodiment 2.

[0031] The arrangement in this embodiment is beneficial to the growth of the crystal along the required crystal phase, and avoids the reduction of the utilization rate of the crystal caused by the excessive length of the seed crystal well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com