A method for denitrification without ammonia in a circulating fluidized bed coal-fired boiler furnace

A circulating fluidized bed, coal-fired boiler technology, applied in fluidized bed combustion equipment, combustion methods, chemical instruments and methods, etc., can solve the problem of high carbon content in bottom slag and fly ash, easy corrosion and coking of boilers and flues , low combustion efficiency and other problems, to achieve the effect of high carbon content, preventing mutual agglomeration and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

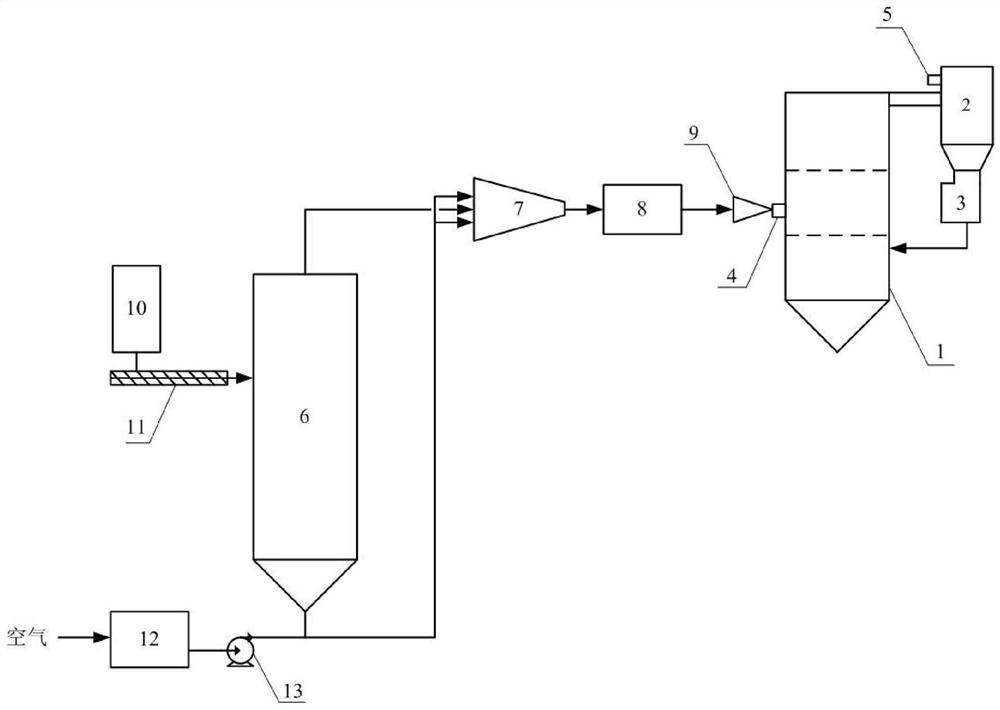

[0049] This embodiment provides a method for denitrification without ammonia in a circulating fluidized bed coal-fired boiler furnace, such as figure 1 As shown, the circulating fluidized bed coal-fired boiler includes a circulating fluidized bed coal-fired boiler 1, a cyclone separator 2, and a feeder 3 connected in sequence, and the anthracite with an average particle size of 500 μm to 550 μm is dispersed and sprayed by powder The system enters the furnace body from the secondary air outlet 4 of the furnace body of the circulating fluidized bed coal-fired boiler 1, and the tertiary air inlet 5 is set at the entrance of the cyclone separator 2, and the material in the return device 2 returns to the circulating fluidized bed coal-fired boiler. the furnace body of the boiler 1;

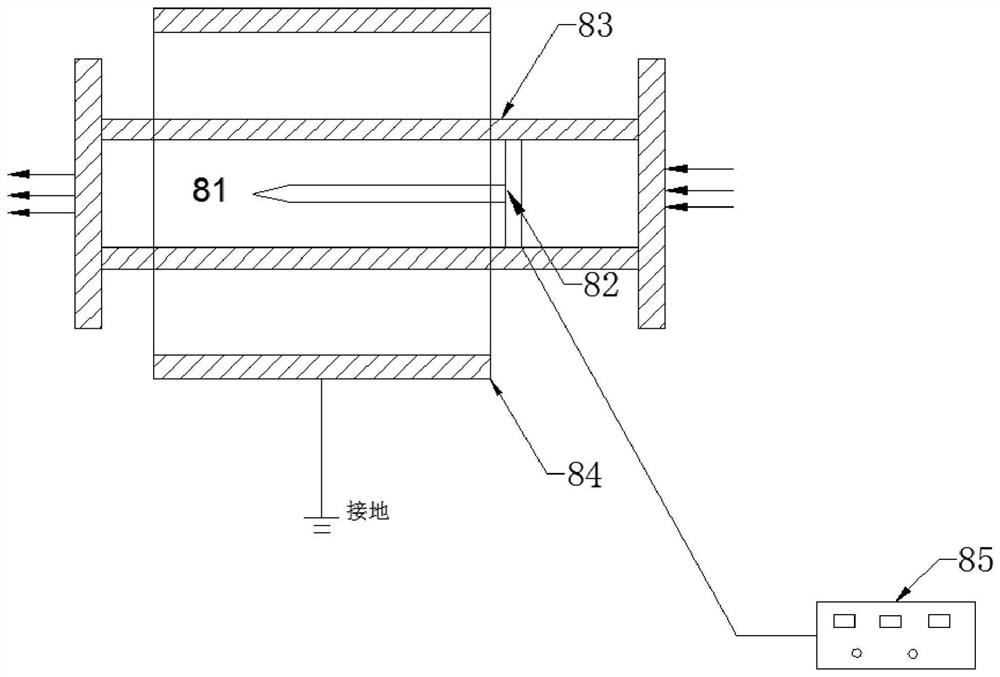

[0050] The powder dispersion and injection system includes a powder fluidization device 6, a high-pressure air flow dispersion device 7, an electrostatic dispersion device 8, and a powder output 9; whe...

Embodiment 2

[0058] This embodiment provides an ammonia-free denitrification method in a circulating fluidized bed coal-fired boiler, wherein the circulating fluidized bed coal-fired boiler includes a circulating fluidized bed coal-fired boiler, a cyclone separator and a feeder connected in sequence, Anthracite with an average particle size of 570 μm ~ 600 μm is passed into the furnace body from the secondary air port of the furnace body of the circulating fluidized bed coal-fired boiler through conventional injection means (such as using a Laval nozzle), and three times are set at the entrance of the cyclone separator. The air inlet, the material in the return device returns to the furnace body of the circulating fluidized bed coal-fired boiler.

[0059] By adopting the method described in this embodiment, the denitrification efficiency of the circulating fluidized bed boiler can reach 26%, and the burnout rate of coal can reach more than 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com