Desulfurization, denitration and dust removal integrated process

A desulfurization, denitrification and process technology, applied in gas treatment, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high water content, high investment, high risk of combustion and explosion, and achieve small footprint, low investment cost, Set up flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

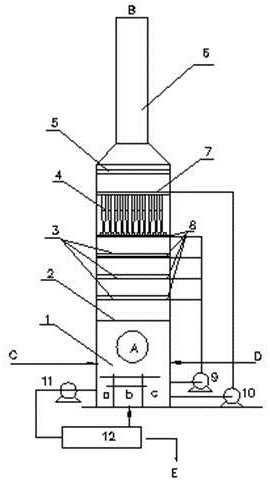

[0042] Example 1 is an example of an integrated process for low-sulfur flue gas desulfurization, denitration and dust removal.

[0043] figure 1 Medium desulfurization, denitrification and dust removal integrated tower 1, swirl plate 2, electrocatalytic layer 3, penetrating liquid film layer 4, demister layer 5, chimney 6, washing spray layer 7, absorption spray layer 8, absorption circulation pump 9 , washing circulation pump 10, filter pump 11, filter 12; flue gas A, purified flue gas B, ammonia water C, washing process water D, solid residue E.

[0044] The desulfurization, denitrification and dust removal integrated tower 1 is equipped with double circulation, with swirl plates 2, 3 electrocatalytic layers 3, penetrating liquid film layers 4 and demisting layers 5 arranged from bottom to top, and 4 absorption spray layers 8 and 1 layer of washing and spraying layer 7; the electrocatalytic reaction layer is composed of supports, electrodes and electroactive fillers, and th...

Embodiment 2

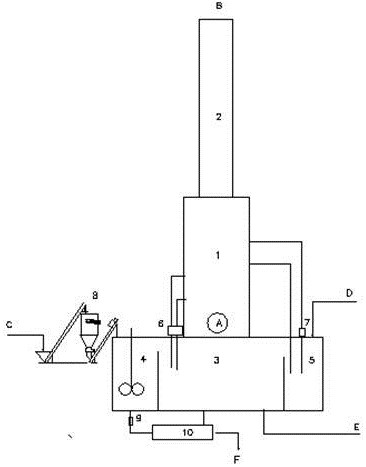

[0049] Example 2 is an example of the integrated desulfurization, denitrification and dust removal process of the tower and pond.

[0050] figure 2 Medium desulfurization, denitrification and dust removal integrated tower 1, chimney 2, slurry tank 3, gypsum whisker preparation tank 4, clear water tank 5, absorption circulation pump 6, washing circulation pump 7, lime automatic dosing device 8, filter pump 9, filter 10; Flue gas A, purified flue gas B, lime C, washing process water D, ammonia water E, gypsum whiskers F.

[0051] The desulfurization, denitrification and dust removal integrated tower 1 is equipped with double circulation, and a conjoined chimney 2 is installed. The conjoined pool is divided into three parts: a slurry pool 3, a gypsum whisker preparation pool 4 and a clear water pool 5;

[0052] Process: The flue gas A enters the bottom of the desulfurization, denitrification and dust removal integrated tower 1, and is in countercurrent contact with the absorption...

Embodiment 3

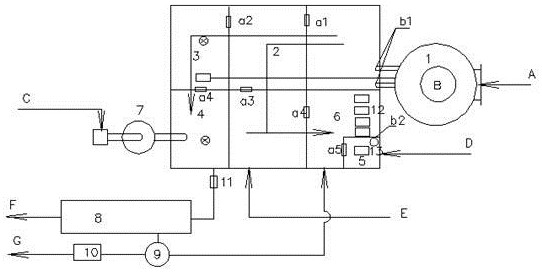

[0056] Embodiment 3 is an example of the integrated process of desulfurization, denitrification and dust removal of tower pool split.

[0057] image 3 Medium desulfurization, denitrification and dust removal integrated tower 1, slurry tank 2, transition slurry tank 3, gypsum whisker preparation tank 4, clear water tank 5, reflux tank 6, absorption circulation pump 6, lime automatic dosing device 7, vacuum belt filter 8 , a gas-liquid separator 9, a vacuum pump 10, a filter 11, an absorption circulation pump 12, and a washing circulation pump 13; communication gaps a1, a2, a3, a4, a5 between the pools, outlet b1 at the bottom of the tower, and outlet b2 for washing water; Flue gas A, purified flue gas B, lime C, washing process water D, ammonia water E, gypsum whiskers F, suction filter exhaust gas G.

[0058] Desulfurization, denitrification and dust removal integrated tower 1 is equipped with double circulation, and a conjoined chimney is installed. The split pool is divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com