Stove heat-insulating shield and stove utilizing stove heat-insulating shield

A technology for heat shields and stoves, which is applied in the field of stoves, and can solve problems such as slippery pans, overflow of cooking soup, swaying combustion flames of gas stoves, and flameout of gas stoves, so as to improve gas utilization, prevent radiation, The effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

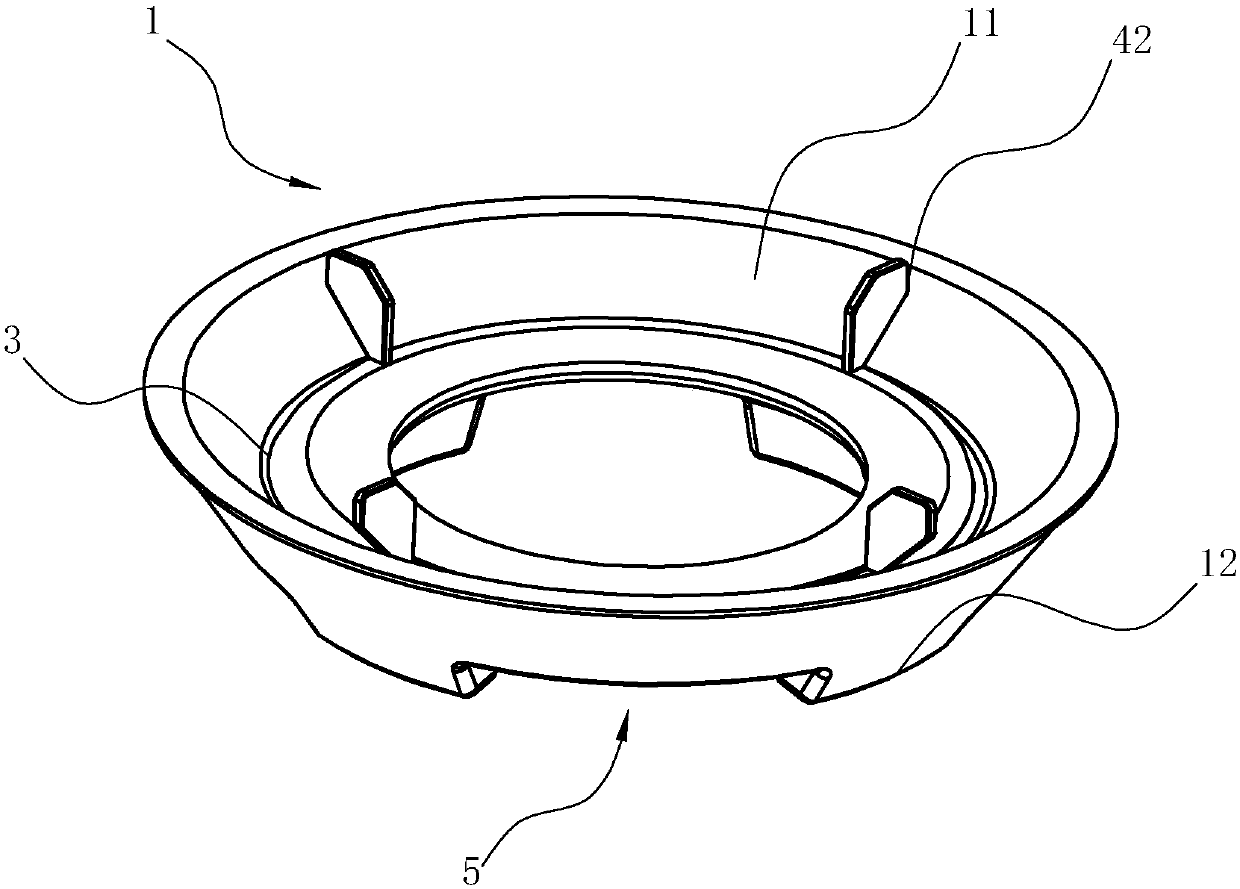

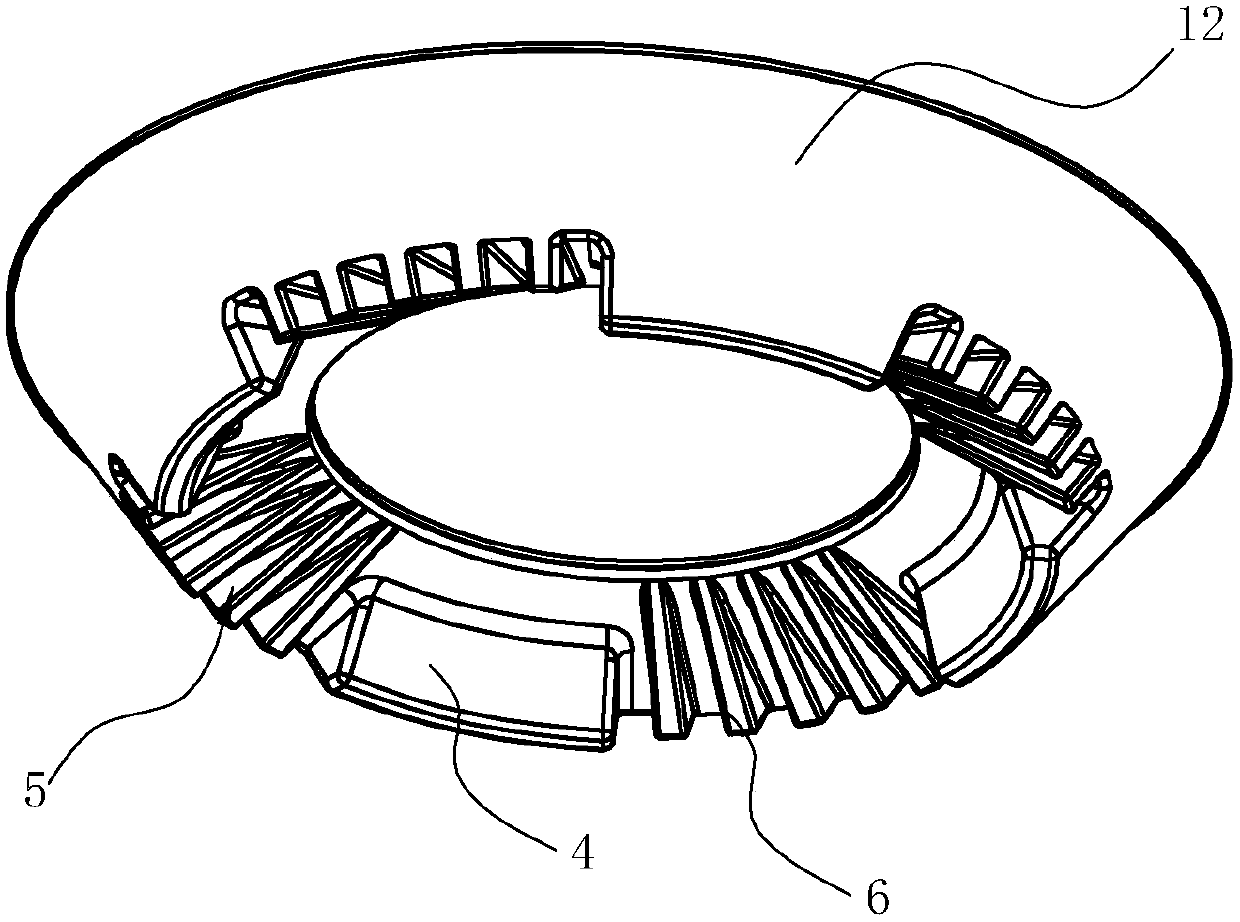

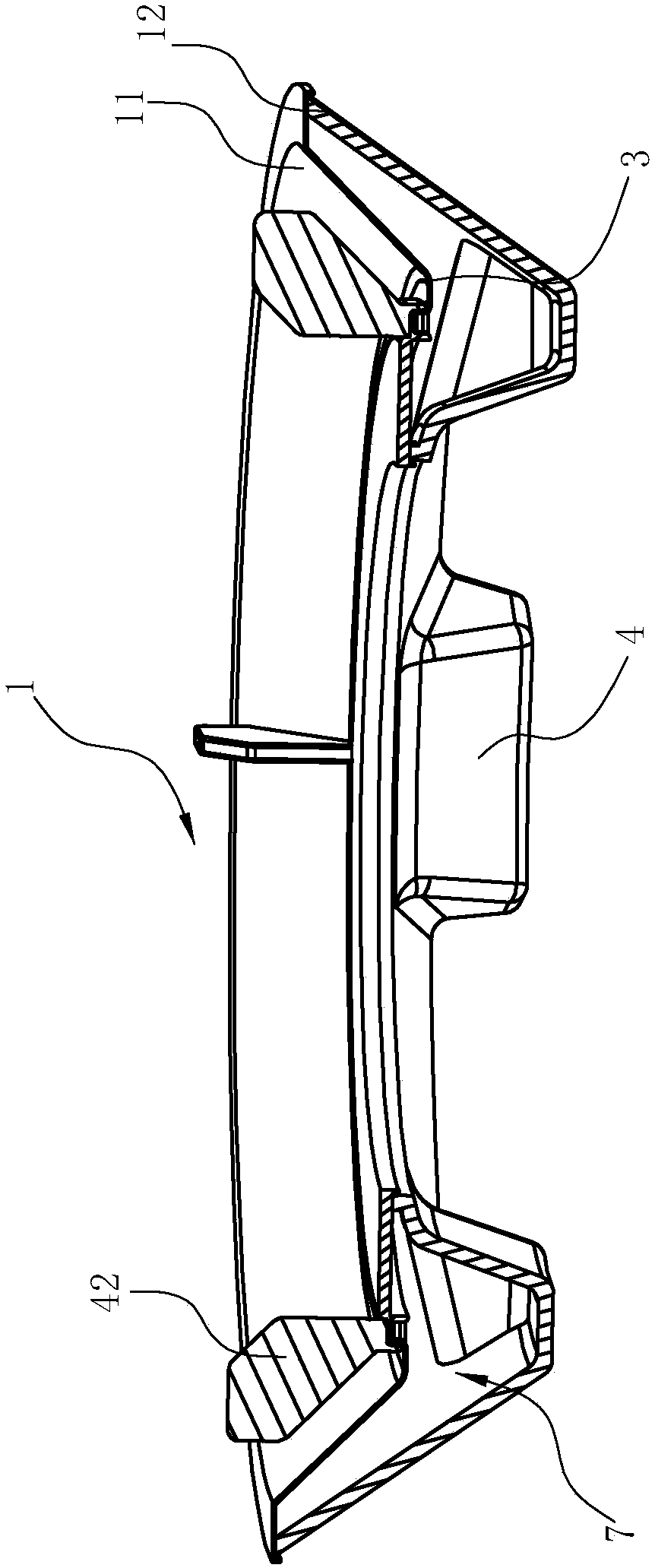

Embodiment 1

[0024] Such as Figure 1~3 As shown, the stove heat shield in this embodiment includes an annular cover body 1, the cover body 1 is a double-layer structure composed of an upper layer cover 11 and a lower layer cover 12, and there is a gap between the upper layer cover 11 and the lower layer cover 12. Cavity 7, the inside of cavity 7 is filled with air, and the poor heat transfer performance of air is used to play the role of thermal insulation, so as to achieve the purpose of high temperature inside the upper cover 11 and low temperature outside the lower cover 12, thereby achieving a high concentration of heat on the inside and a high degree of heat on the outside. The effect of less heat dissipation, wherein, the lower cover 12 forms the legs 4 by being recessed, causing the legs 4 to also be in a hollow structure. On the one hand, increasing the volume of the cavity of the legs 4 increases the capacity of the air in the cavity, which can effectively reduce the pressure of t...

Embodiment 2

[0030] Such as Figure 5 As shown, the structure is basically the same as that of Embodiment 1, the difference being that the cover body 1 is square.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com