Method for stimulating probe to vibrate in atomic force microscope

An atomic force microscope and probe technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve problems such as imaging failure, increased equipment requirements, and decreased probe oscillation amplitude to achieve low performance Requirements, the effect of reducing equipment requirements and increasing the possibility of realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

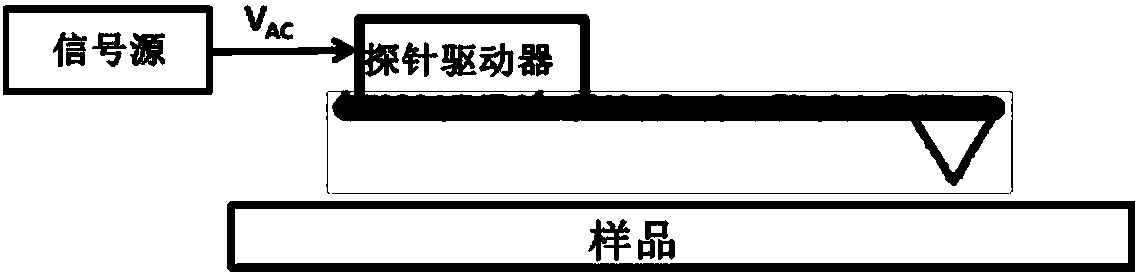

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, an AFM model of Aglient 5500 is used. In the AFM, a nanometer-scale probe is fixed on a micrometer-scale elastic cantilever. The probe is a silicon probe with a force constant of 0.1 N / m.

[0028] In this embodiment, the sample to be tested is graphene, and the graphene is covered on a silicon substrate with a 250 nm deep hole structure to form a partially suspended graphene sample.

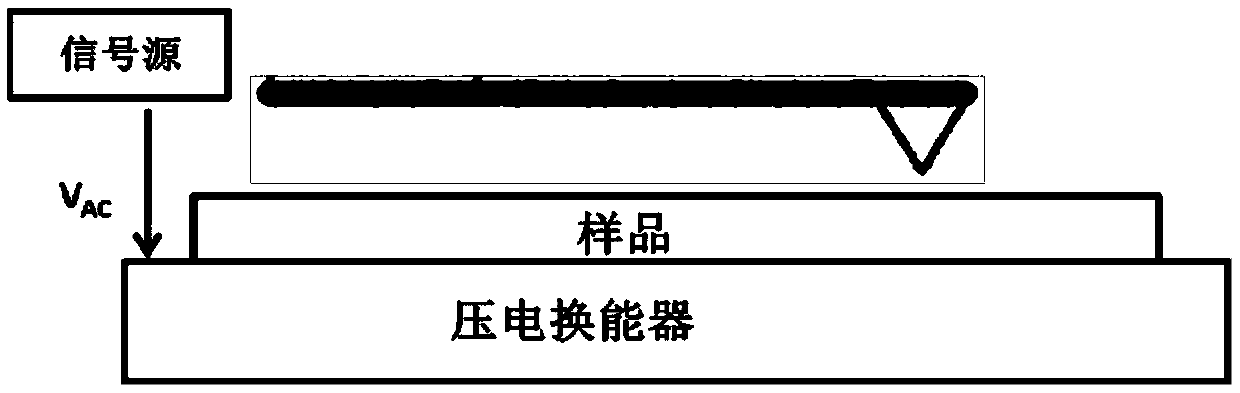

[0029] Such as figure 2 As shown, the piezoelectric transducer is fixed on the sample stage of the atomic force microscope, and the sample to be tested is fixed on the surface of the piezoelectric transducer by glycerin;

[0030] With the probe positioned above the sample, bring the probe close to the sample surface. The contact mode of the atomic force microscope can be used to make the tip touch the sample first, and then the tip can be raised, and the raising distance can be set to 5um-100um. In this embodiment, it is set to 10um.

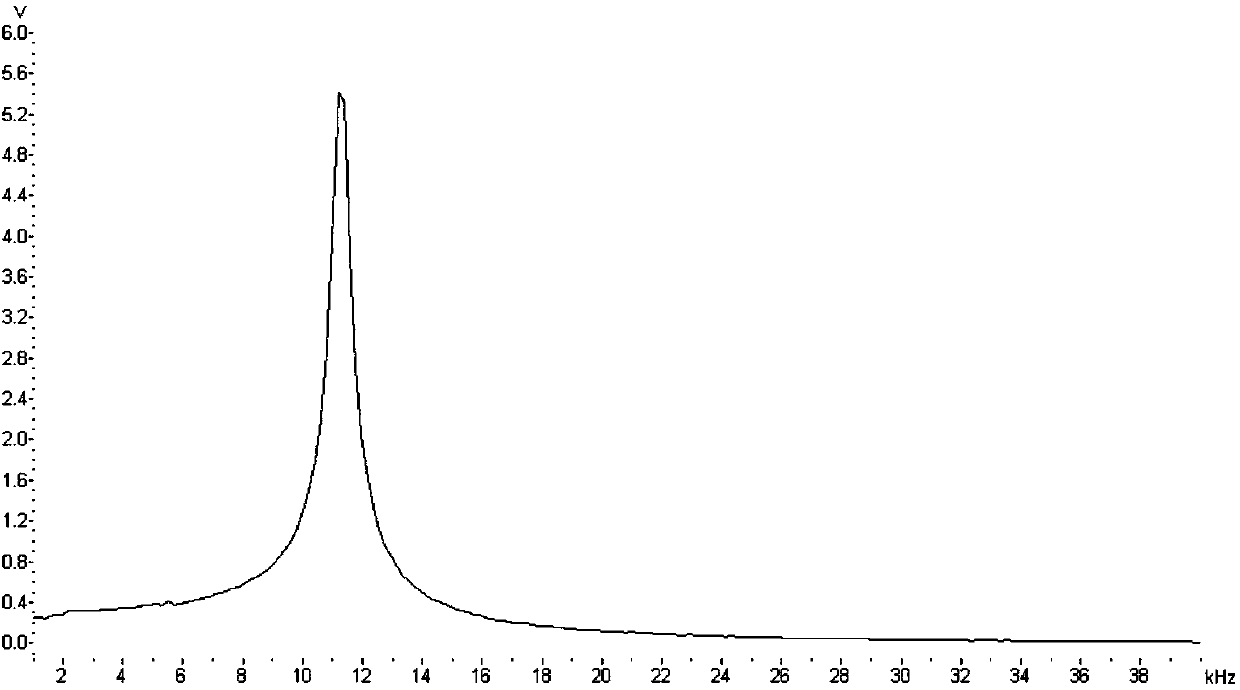

[0031] The atomic force micros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com