Nickel-cobalt-manganese ternary positive electrode spherical material and preparation method thereof

A nickel-cobalt-manganese and cathode technology is applied in the field of nickel-cobalt-manganese ternary cathode spherical material and its preparation, which can solve the problems of high difficulty in operation and large pollution, and achieve the effects of simple operation process, improved electrical performance, and removal of residual alkali.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

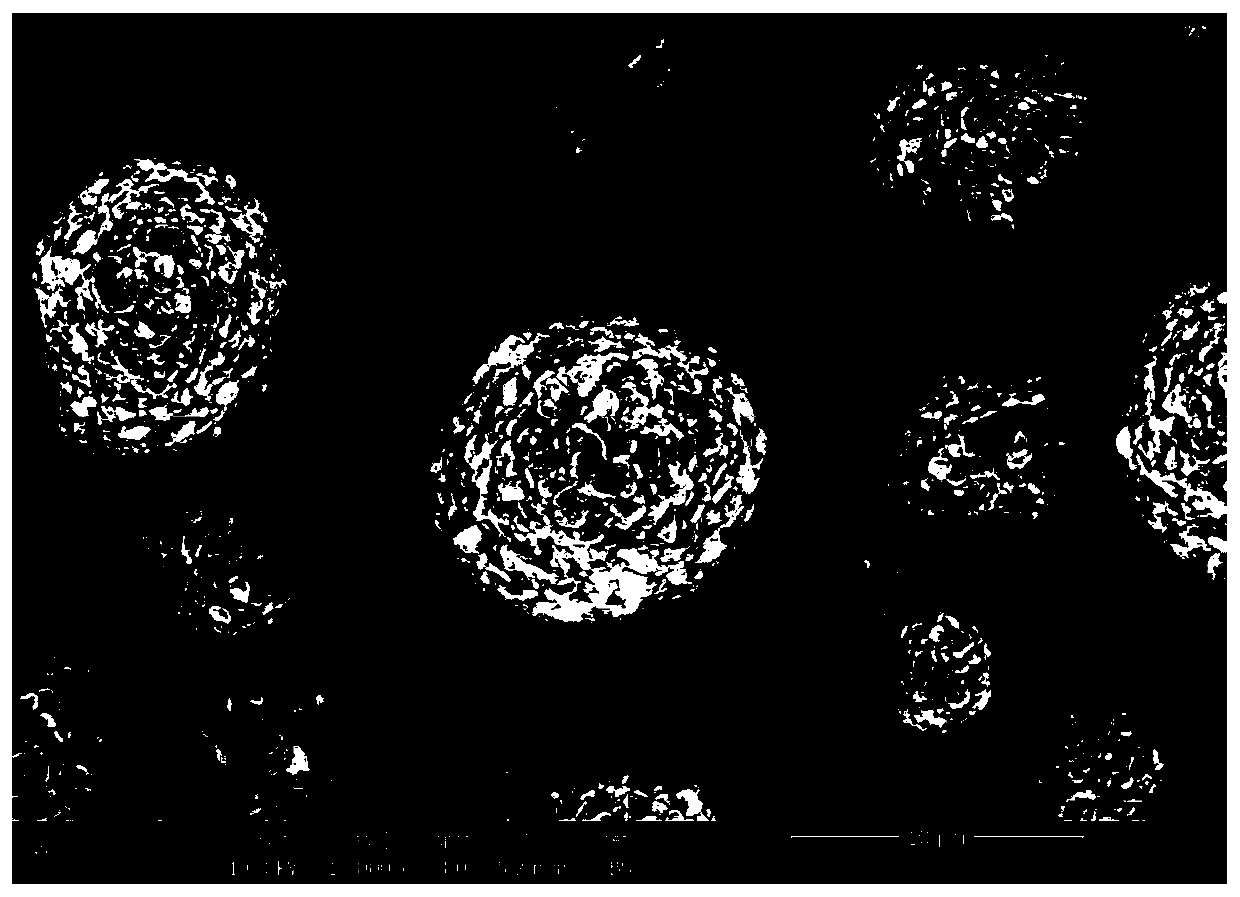

Embodiment 1

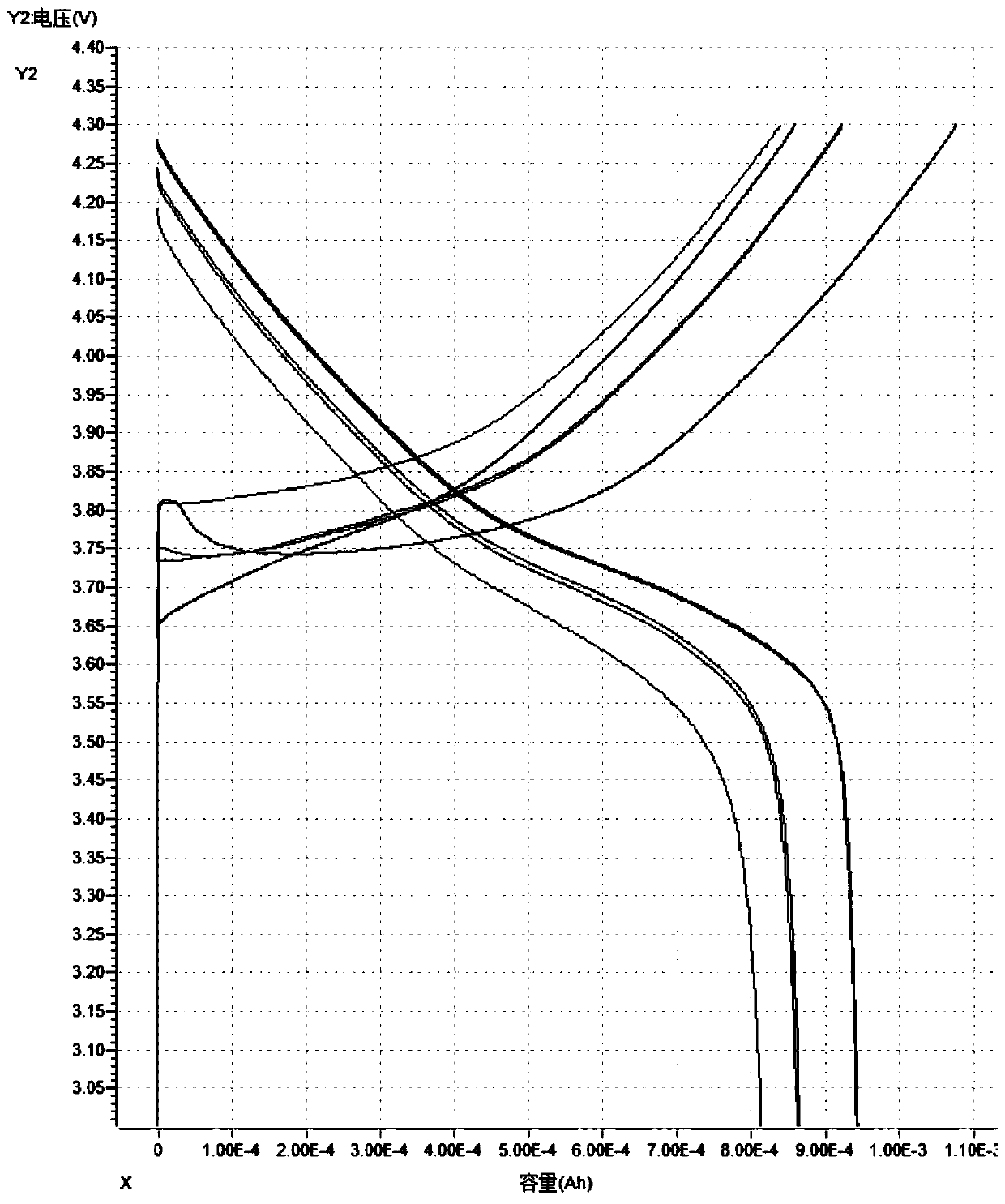

[0034] According to the molar ratio n(Ni+Co+Mn):n(Li)=0.3, take a total of 100kg of nickel-cobalt-manganese ternary precursor (622 type) and lithium source, and take 10kg V at the same time 2 o 5 , 40kg of nano-mesoporous silica, put the above materials into a high-mixer and mix for 2 hours to obtain a mixture; calcinate the mixture at 900°C for 12 hours in an air-filled roller furnace, and then crush and classify it, then put it into Mix and coat with 1kg of VDF in a high mixer for 1 hour; then calcinate in an air-filled roller furnace at 400°C for 5 hours. The secondary sintered material is crushed, classified, screened and demagnetized in sequence to obtain the finished product. Take the finished product for SEM characterization results see figure 1 ,Depend on figure 1 It can be seen that the positive electrode material particles are uniformly spherical and compact in structure.

Embodiment 2

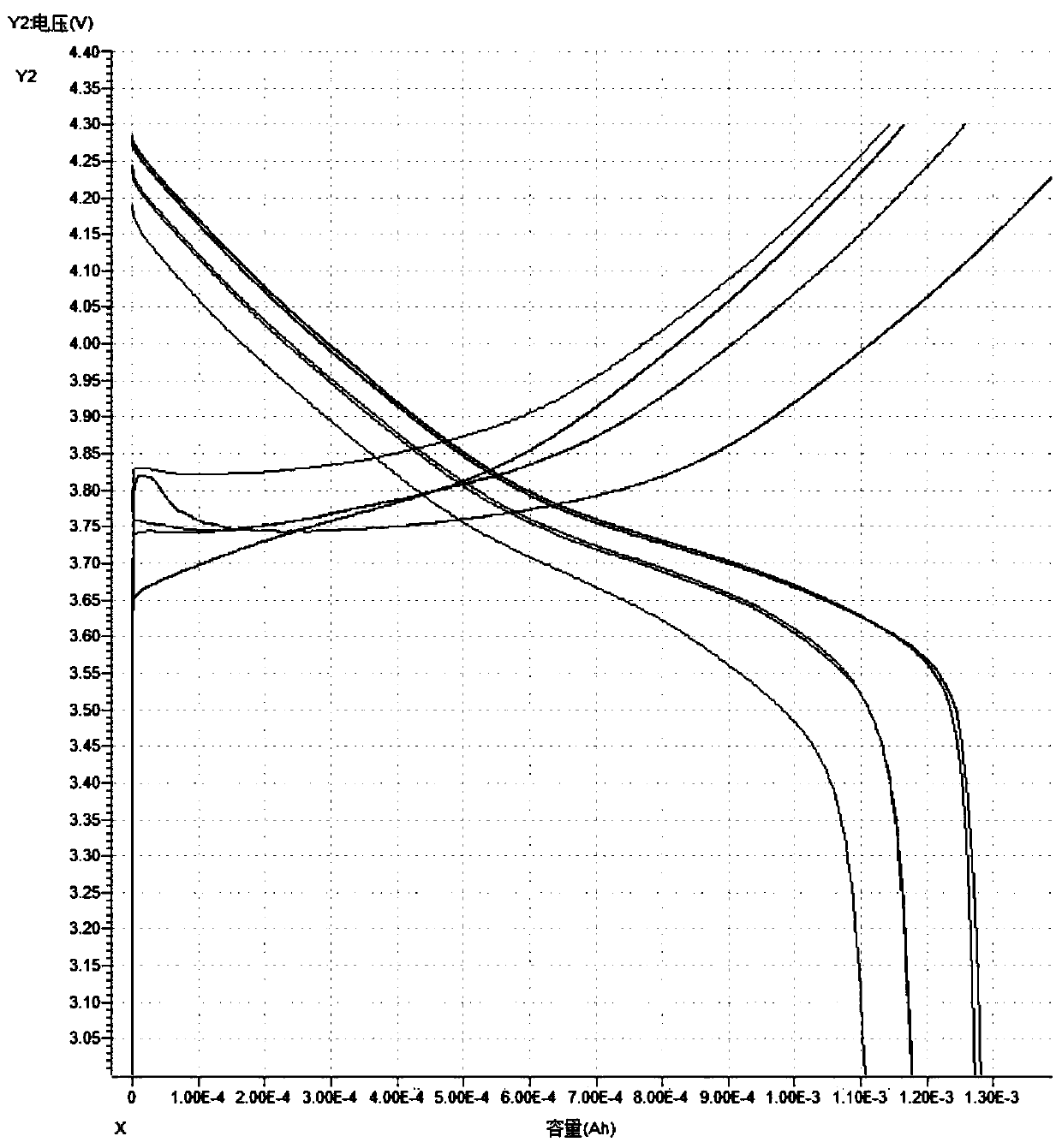

[0036] According to the molar ratio n(Ni+Co+Mn):n(Li)=0.4, take a total of 100kg of nickel-cobalt-manganese ternary precursor (type 622) and lithium source, and take 12kg V at the same time 2 o 5 , 40kg of nano-mesoporous silica, put the above materials into a high-mixer and mix for 2 hours to obtain a mixture; calcinate the mixture at 900°C for 13 hours in an air-filled roller furnace, and then crush and classify it, then put it into Mix and coat with 0.8kg of VDF in a high mixer for 1 hour; then calcinate in an air-filled roller furnace at 400°C for 7 hours. The secondary sintered material is crushed, classified, screened and demagnetized in sequence to obtain the finished product. Take the finished product for SEM characterization results see figure 2 , it can be seen from Figure 2 that the positive electrode material particles are uniformly spherical and compact in structure.

Embodiment 3

[0038] According to the molar ratio n(Ni+Co+Mn):n(Li)=0.3, take a total of 100kg of nickel-cobalt-manganese ternary precursor (type 622) and lithium source, and take 15kg V at the same time 2 o 5 , 30kg of nano-mesoporous silica, put the above materials into a high-mixer and mix for 2 hours to obtain a mixture; calcinate the mixture at 850°C for 15 hours in an air-filled roller furnace, and then crush and classify it, then put it into Mix and coat with 0.6kg of VDF in a high mixer for 1 hour; then calcinate at 400°C for 5 hours in an air-filled roller furnace. The secondary sintered material is crushed, classified, screened and demagnetized in sequence to obtain the finished product. Take the finished product for SEM characterization results see image 3 , it can be seen from Figure 3 that the positive electrode material particles are uniformly spherical and compact in structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com