Mechanical automatic preserved prune processing system

A processing system and prune technology, applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of high labor intensity, low degree of mechanization, and manual operation, so as to improve the quality and processing efficiency, and improve the piercing. Efficiency, the effect of improving osmotic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

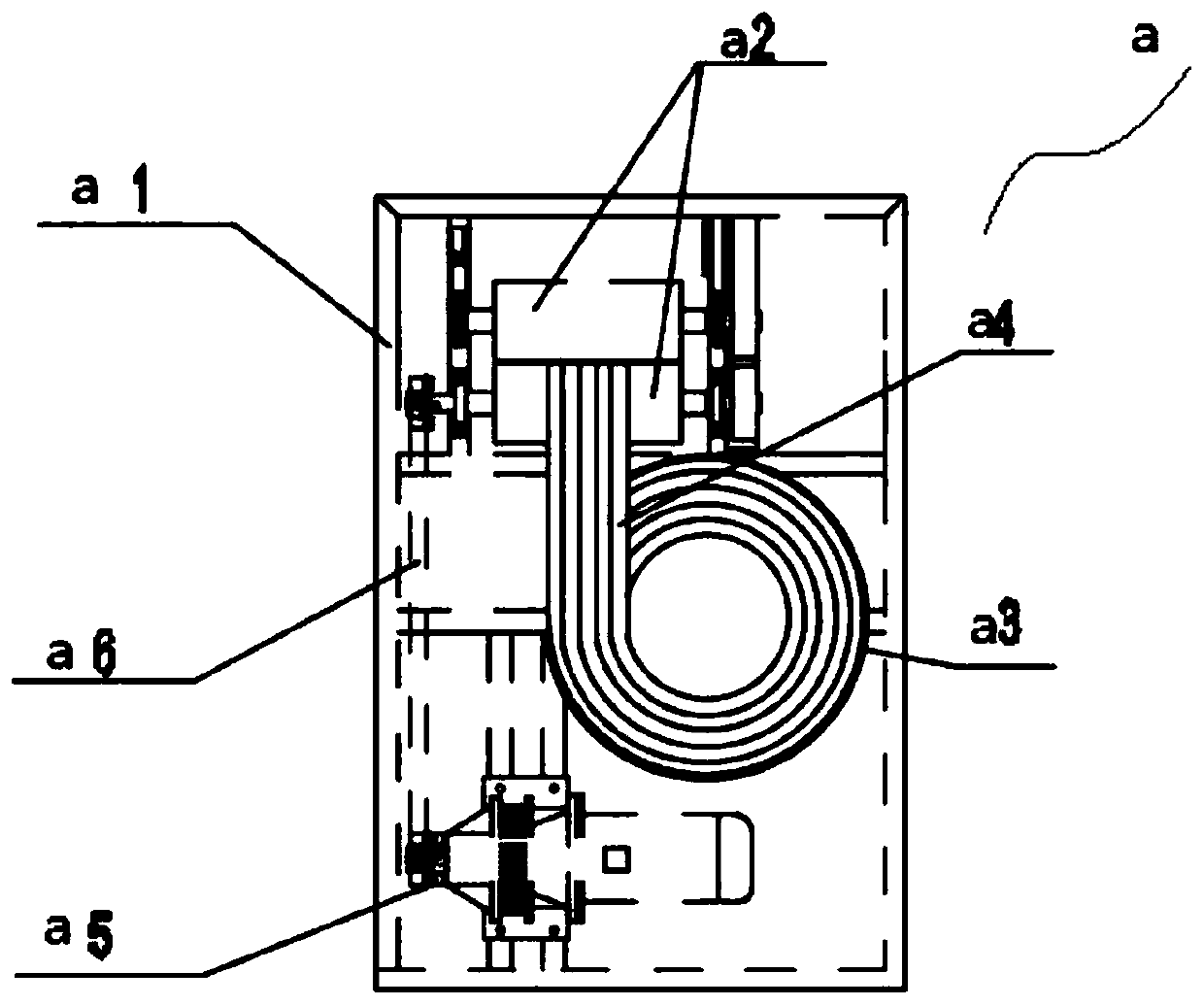

[0075] An embodiment of the present invention also includes a drive motor a5 for driving the licker-in roller a2 to rotate, and a synchronous conveyor belt a6 for power transmission; one end of the synchronous conveyor belt a6 is sleeved on the shaft wheel of the roller shaft, and the other end is sleeved On the runner of the drive motor a5. The driving motor a5 drives the licker-in roller a2 to rotate through the synchronous conveyor belt a6.

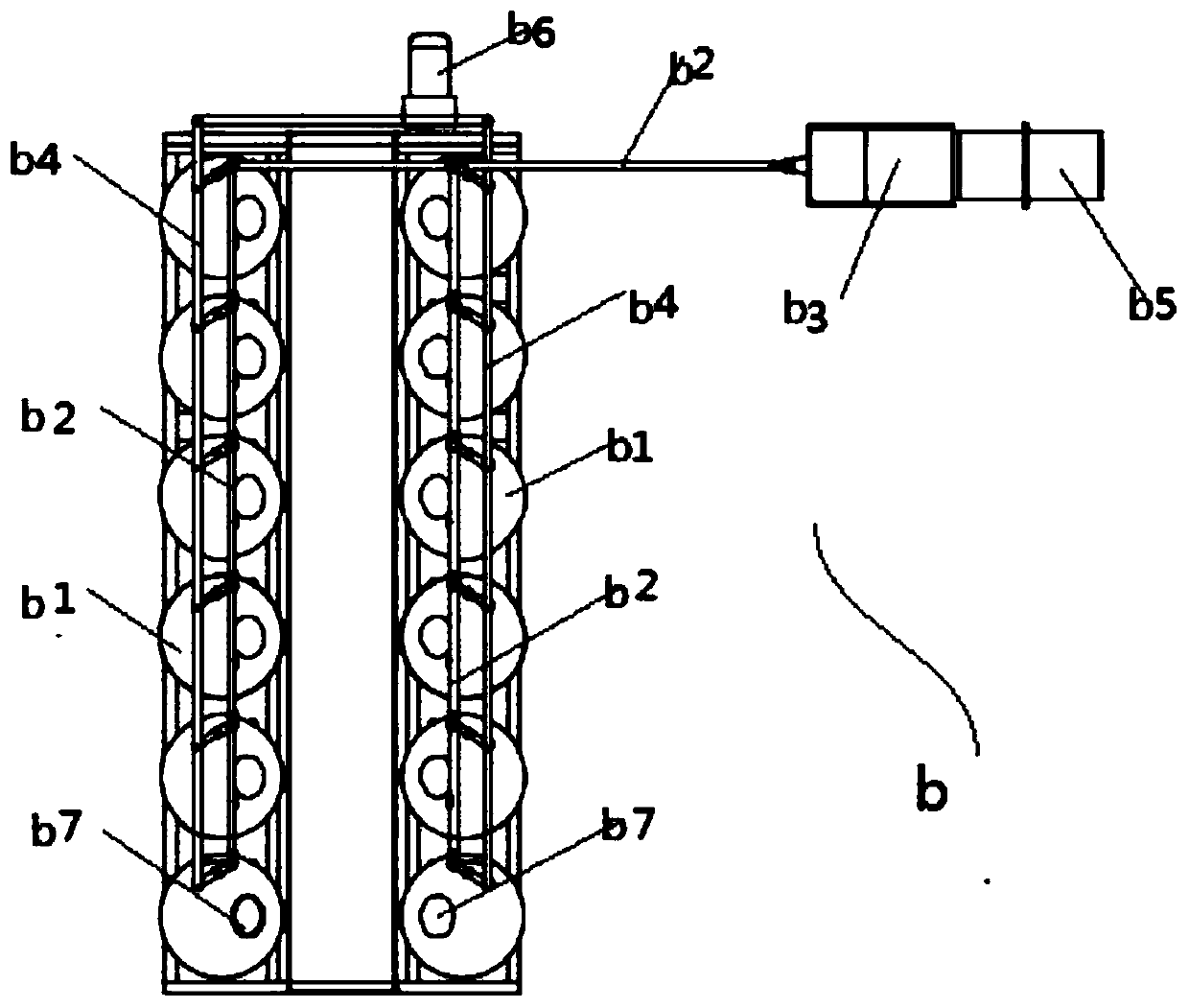

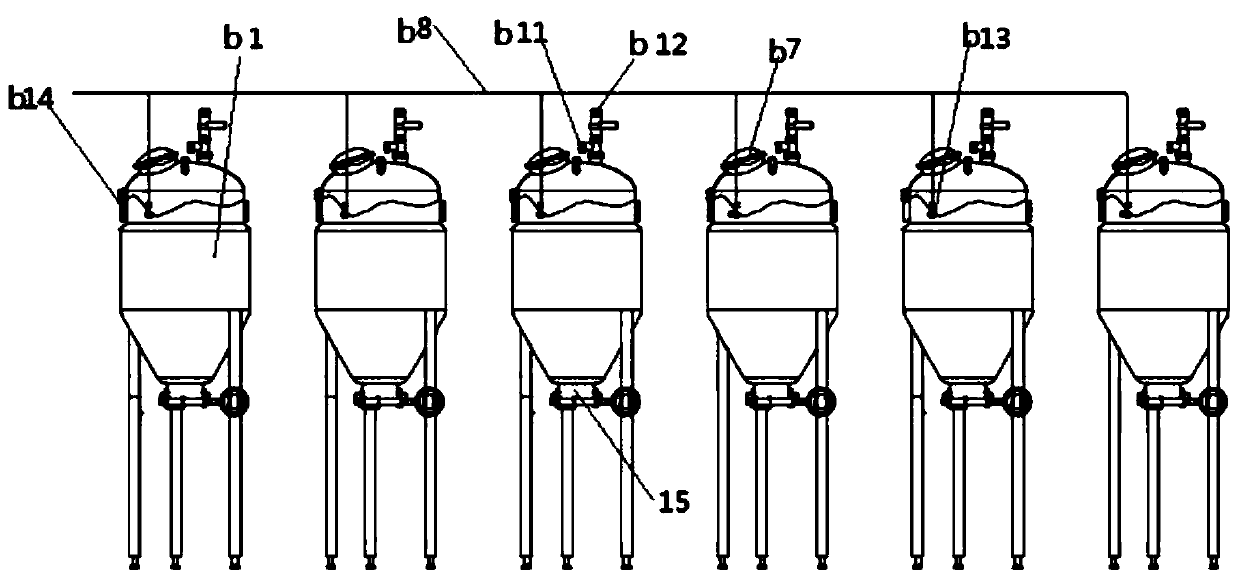

[0076] In one embodiment of the present invention, the sugar osmosis and sugar extraction system includes a vacuum sugar osmosis device b,

[0077] The vacuum sugar osmosis device includes a vacuum sugar osmosis tank, and a vacuum generator is arranged on the top of the vacuum sugar osmosis tank; the vacuum generator uses a large flow vortex air pump to generate a large flow of vacuum at the fluid constriction of the Venturi tube of the vacuum generator. Gas, the pierced fruit base is pneumatically fed into the sugar soaking tank thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com