Organic pigment hyperdispersant, preparation method thereof, pigment composition and water-based ink

A technology of organic pigments and super dispersants, applied in the field of pigment compositions and water-based inks, can solve the problems of reducing ink viscosity and high viscosity, and achieve the effects of speeding up drying speed, increasing ratio and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The above preparation method has the advantages of high yield, simple operation, environmental protection and the like.

[0048] Another aspect of the present invention also provides a kind of pigment composition, comprises component A and component B, wherein,

[0049] Component A is composed of at least one organic pigment, and the organic pigment is mainly naphthol-based organic pigments, such as Pigment Red 2, Pigment Red 5, Pigment Red 7, Pigment Red 8, Pigment Red 9, Pigment Red 10, Pigment Red 11, Pigment Red 12, Pigment Red 13, Pigment Red 14, Pigment Red 15, Pigment Red 16, Pigment Red 17, Pigment Red 18, Pigment Red 19, Pigment Red 21, Pigment Red 22, Pigment Red 23, Pigment Red 30, Pigment Red 31, Pigment Red 32, Pigment Red 38, Pigment Red 95, Pigment Red 112, Pigment Red 114, Pigment Red 119, Pigment Red 146, Pigment Red 147, Pigment Red 148, Pigment Red 157, Pigment Red 162, Pigment Red 170, pigment red 187, pigment red 188, pigment red 210, pigment red 2...

Embodiment 1

[0055] Embodiment 1: the synthesis of hyperdispersant naphthol AS-L207

[0056] Stir 2.63 parts of naphthol AS and 20.7 parts of Huntsman L207 evenly at 40°C, add 0.3 parts of paraformaldehyde and 0.25 parts of glacial acetic acid, stir and react at 120°C for 4 hours, use thin-layer chromatography to spot the plate, after the reaction is completed It was purified through a 200-300 mesh silica gel column, and the eluent was petroleum ether and ethyl acetate. After rotary evaporation, 10.3 parts of the product were obtained.

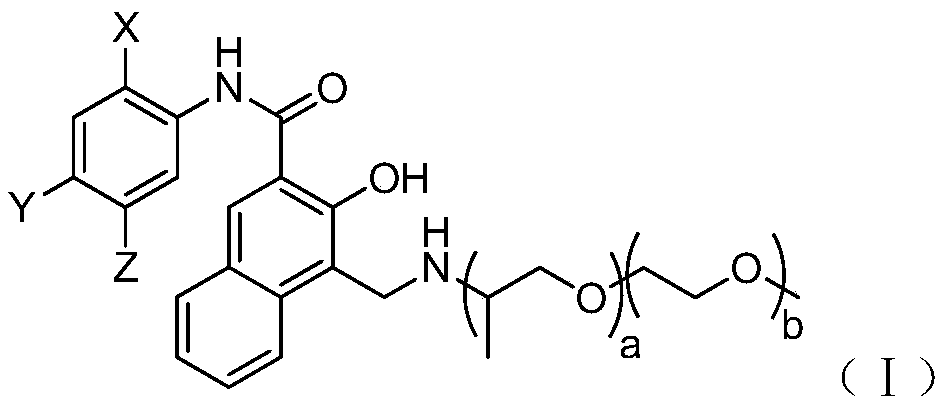

[0057] The molecular formula of the product is shown in Formula IV:

[0058]

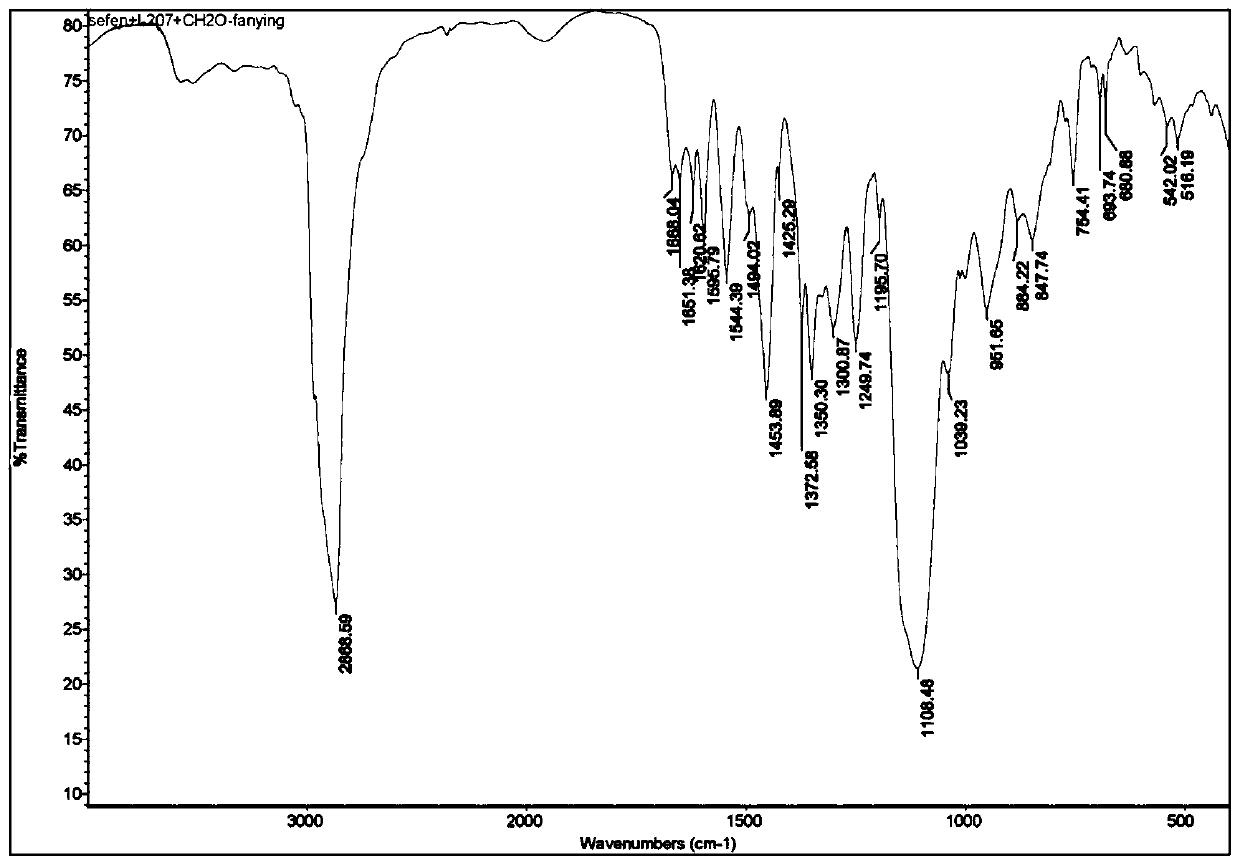

[0059] figure 1 Be the infrared spectrogram of the product of this embodiment, wherein 2869cm -1 It is the characteristic peak of C-H stretching in the alkyl group, 1454cm -1 and 1373cm -1 Is the characteristic peak of alkyl deformation vibration, 1108cm -1 It is a strong absorption peak of the asymmetric stretching vibration of the ether bond. Polyetheramine has a large...

Embodiment 2

[0060] Embodiment 2: the synthesis of hyperdispersant naphthol AS-L100

[0061] Stir 2.63 parts of naphthol AS and 11 parts of Huntsman L100 evenly at 40°C, add 0.6 parts of paraformaldehyde and 0.14 parts of p-toluenesulfonic acid, stir and react at 120°C for 3 hours, spot the plate with thin-layer chromatography, and react After completion, it was purified through a 100-200 mesh silica gel column, the eluent was petroleum ether and ethyl acetate, and 6.2 parts of the product were obtained after rotary evaporation.

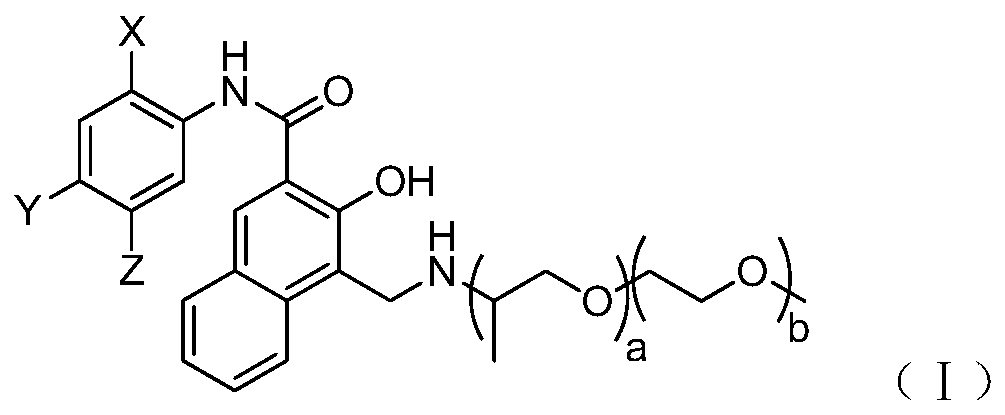

[0062] Product molecular formula is as shown in formula V:

[0063]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap