Auxiliary equipment for oil digging

An auxiliary equipment and petroleum technology, which is applied in the direction of drilling equipment, drill pipes, drill pipes, etc., can solve the problems of inability to well disperse soil extrusion force, high cost of drill pipe protection sleeves, and easy damage of protection sleeves. To achieve the effect of being conducive to environmental protection, improving universality and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

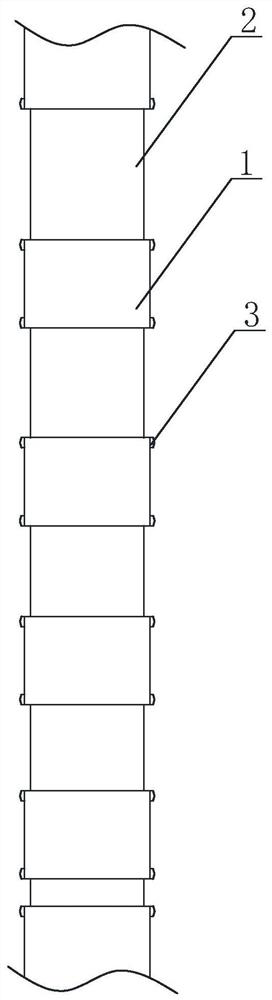

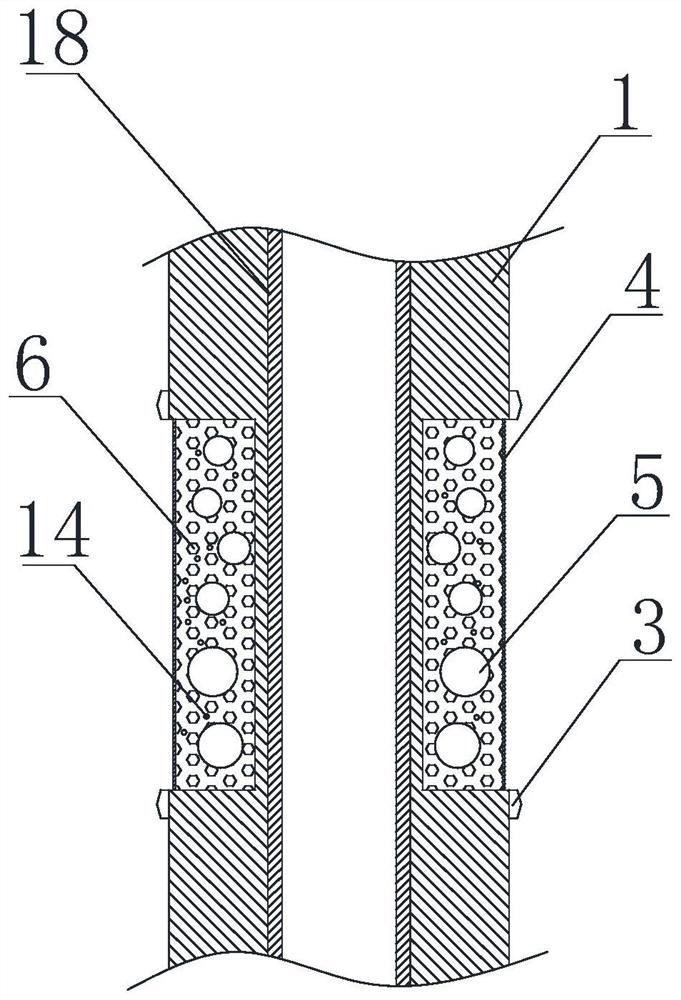

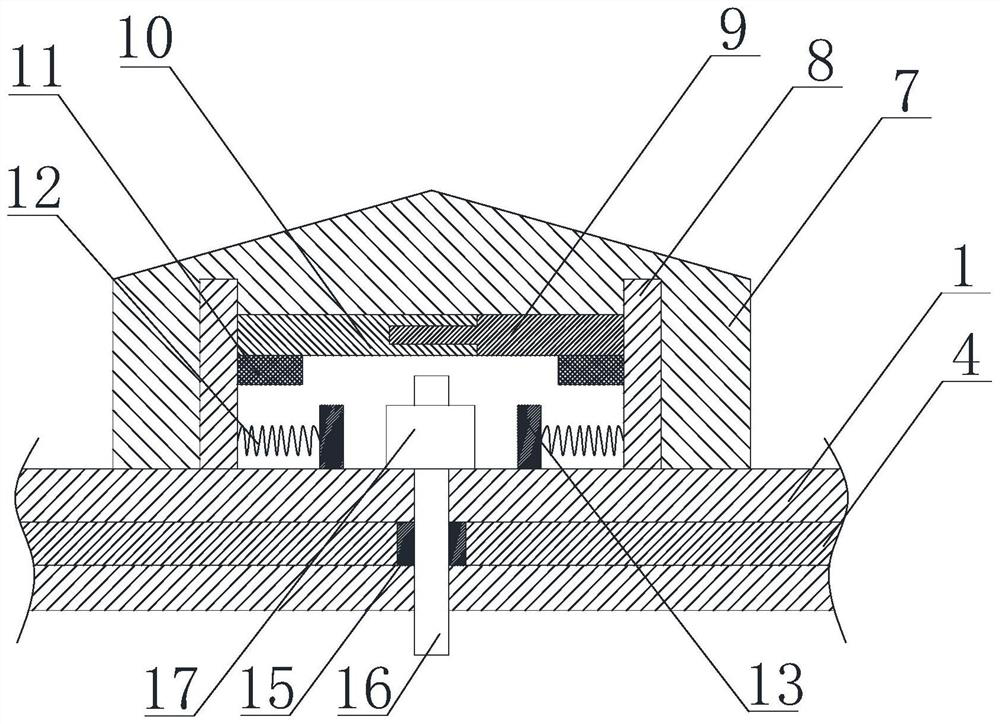

[0029] Such as Figure 1 to Figure 3 As shown, an auxiliary equipment for oil excavation includes a cylinder body 1, and a plurality of annular grooves are arranged on the cylinder body 1, the generatrices of the annular grooves are coaxial with those of the cylinder body 1, and the annular grooves The groove separates the cylinder 1 into a plurality of rigid parts, and a flexible part 2 is arranged in the annular groove, and the height of the flexible part 2 gradually decreases along the direction from the upper end of the cylinder 1 to the lower end of the cylinder 1; the flexible part 2 includes Leather layer 4, the top of described leather layer 4 is placed in the notch that is positioned at the upper surface of annular groove, the bottom of leather layer 4 is placed in the notch that is positioned at the lower surface of annular groove, and leather layer 4 top and bottom are all provided with A plurality of fixing rings 15 also include a plurality of bolts 16 and nuts 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com