High-flexibility and high-resolution photosensitive epoxy acrylic resin composition

A technology of photosensitive epoxy acrylic and resin composition, which is applied in the direction of optics, photomechanical equipment, photoplate making process of patterned surface, etc., can solve the problems of high cost, high risk, poor heat resistance, etc., and achieve high The effect of resolution and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

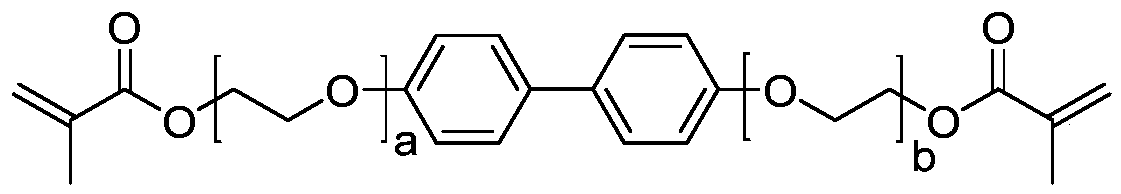

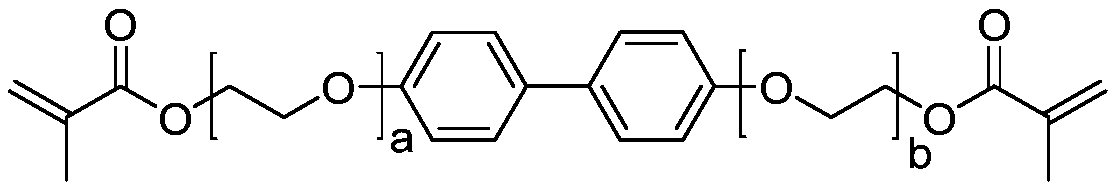

[0022] The preparation of the high-resolution photosensitive epoxy acrylic resin composition: successively add 2.0g acrylic acid monomer (wherein 0.5g ethoxylated bisphenol A diacrylate , 1.5g 30 ethoxy bisphenol A dimethacrylate), 0.6g photopolymerization initiator (0.3g 2959, 0.3g 907), 0.003g photosensitizer (ITX), 6.0g epoxy resin (3.0 Bisphenol A epoxy resin (g, 3.0g toughened epoxy resin), 0.20g yellow pigment P3440, 0.5g other additives, stirred at high speed to dissolve and disperse, and finally filtered to obtain the composition, and stored in dark light for future use.

Embodiment 2

[0024] The preparation of the photosensitive epoxy acrylic resin composition of high resolution: successively add 2.0g acrylic acid monomer (wherein 0.5g polyethylene glycol (400) diacrylic acid ester, 1.5g30 ethoxy bisphenol A dimethacrylate), 0.6g photopolymerization initiator (0.3g 2959, 0.3g 907), 0.003g photosensitizer (ITX), 6.0g epoxy resin (3.0 Bisphenol A epoxy resin (g, 3.0g toughened epoxy resin), 0.20g yellow pigment P3440, 0.5g other additives, stirred at high speed to dissolve and disperse, and finally filtered to obtain the composition, and stored in dark light for future use.

Embodiment 3

[0026] The preparation of the high-resolution photosensitive epoxy acrylic resin composition: successively add 2.0g acrylic acid monomer (wherein 0.5g polypropylene glycol (600) diacrylate, 1.5 g30 ethoxylated bisphenol A dimethacrylate), 0.6g photopolymerization initiator (0.3g 2959, 0.3g 907), 0.003g photosensitizer (ITX), 6.0g epoxy resin (3.0 bisphenol A Epoxy resin (g, 3.0g toughened epoxy resin), 0.005g boron trifluoride ethylamine latent curing accelerator, 0.20g yellow pigment P3440, 0.5g other additives, high-speed stirring to dissolve, disperse, and finally filter to obtain The composition is stored in dark light for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com