Method for cleaning liquid effluents of a wet scrubber treating exhaust fumes emitted by a diesel engine

A technology of wet scrubbers and scrubbers, applied in chemical instruments and methods, using liquid separation agents, separation methods, etc., can solve problems such as difficult to use ships, need maintenance, and high cost of rotating machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

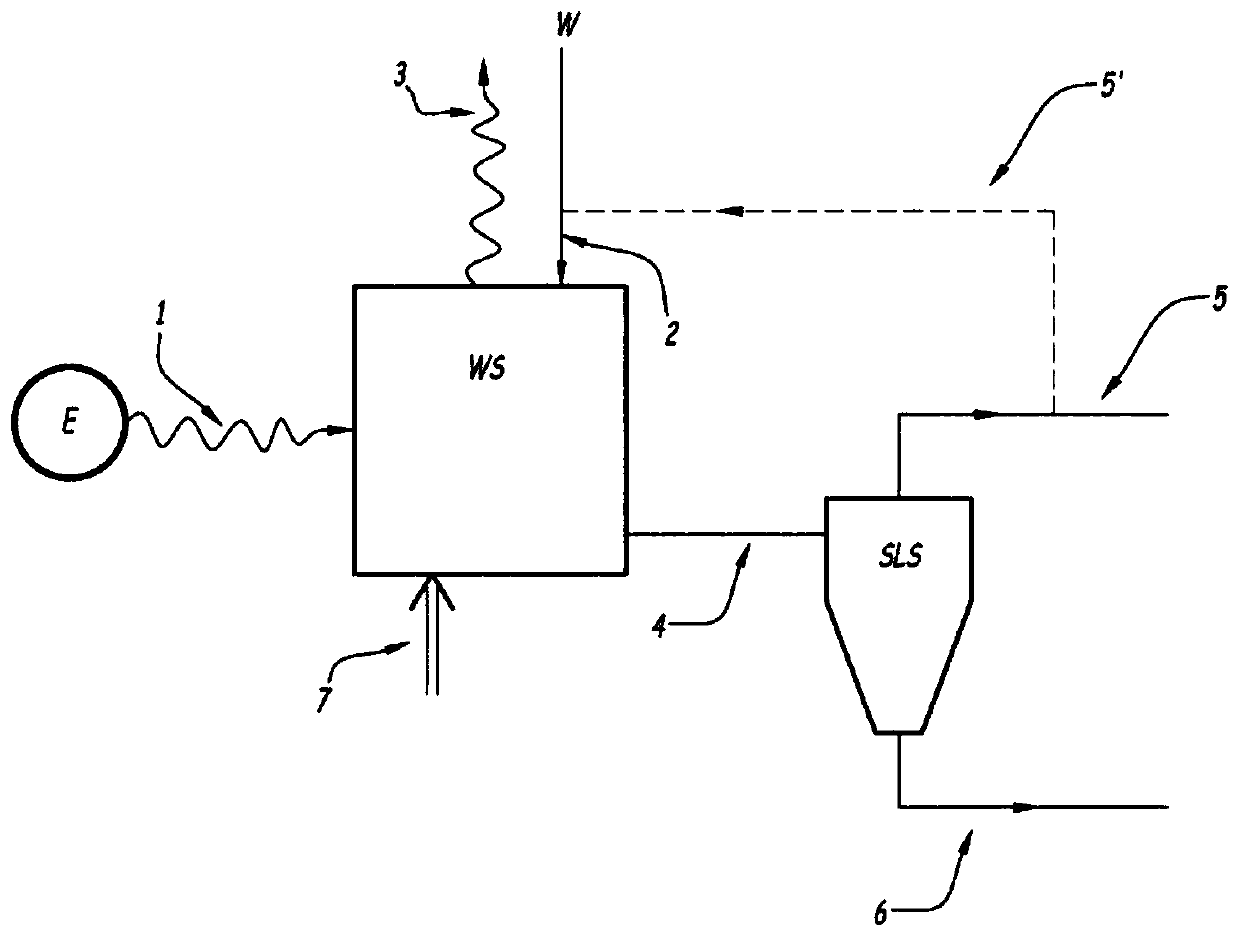

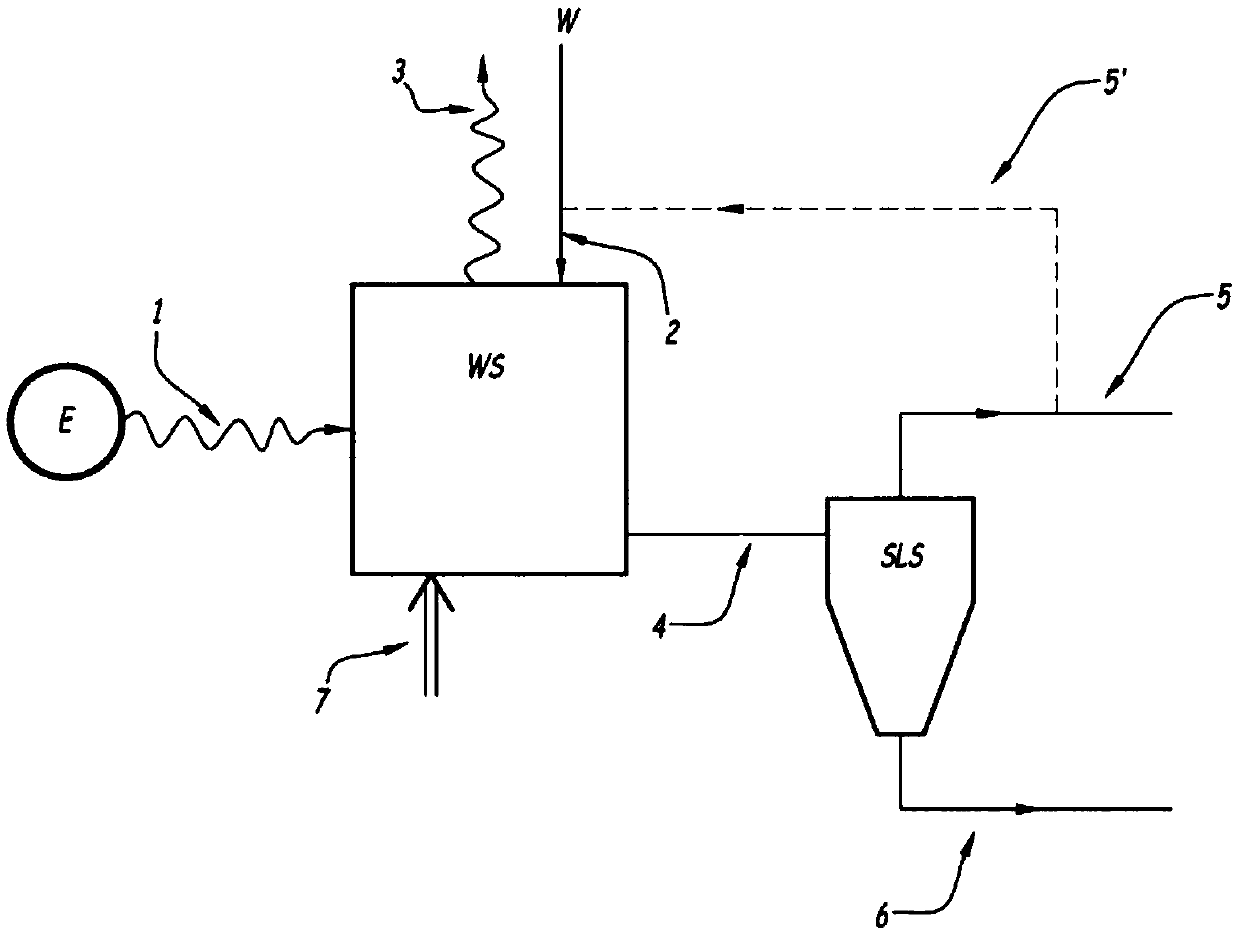

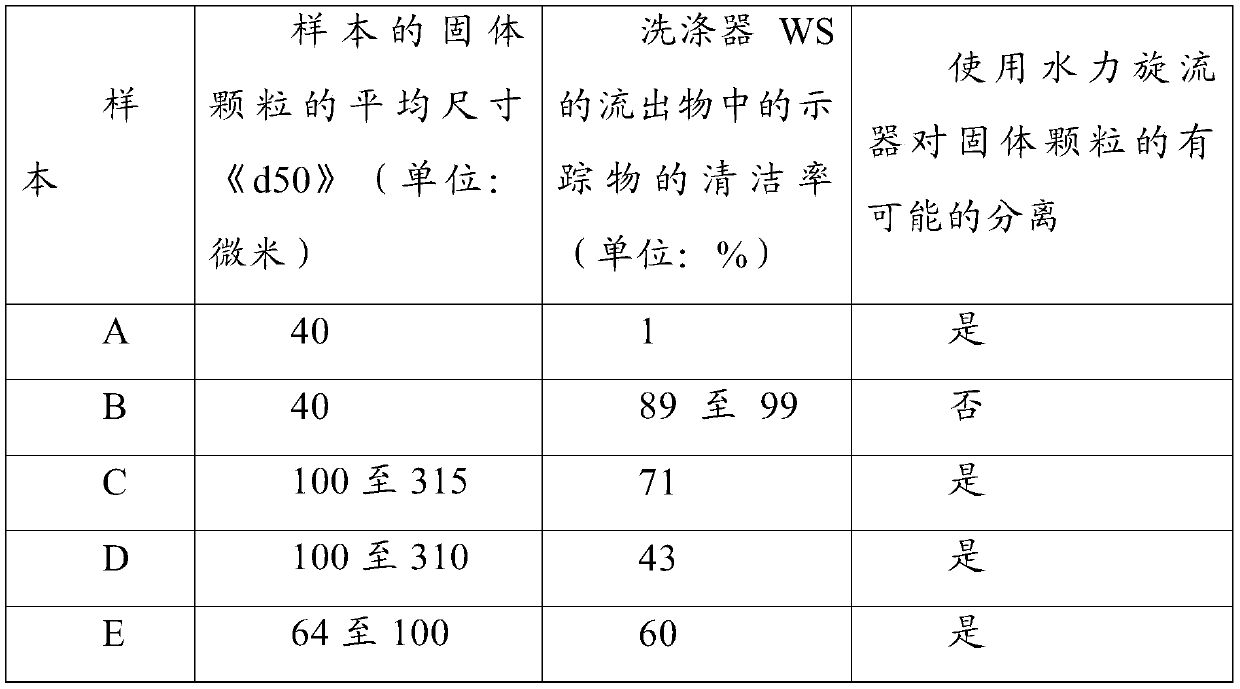

[0013] figure 1 A device for realizing the treatment of exhaust gas 1 emitted by a diesel engine E is illustrated. According to a preferred but non-limiting context of use, the engine E ensures the propulsion of the sea vessel on which it is installed. In all cases, engine E runs on fuel containing sulfur, especially fuel oil, and as a result, in addition to carbon (CO 2 ), water vapor (H 2 O), nitrogen (N 2 ) and oxygen (O 2 ) and other main components, flue gas 1 also contains sulfur oxides, especially sulfur dioxide (SO 2 ). Flue gas 1 also contains nitrogen oxides (NO x ), and organic compounds generated by combustion inside the engine E. These organic compounds include: inter alia soot, tars, oils (especially in aerosol form), aromatic hydrocarbons (such as PAH), aromatic organochlorine compounds (such as PCBs), dioxins and furans (such as PCDD / F), and other inorganic compounds.

[0014] The plant comprises two functional units, a wet scrubber WS, which treats th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com