Stereoscopic curved-blade type drill assembly

A blade type, drill bit technology, applied in the direction of excavation/covering trenches, agriculture, application, etc., can solve the problems of inability to adapt to soil working conditions, weak drilling ability of the drill bit assembly, low drilling efficiency, etc. The effect of soil splashing, improving drilling capacity and applicable working conditions, and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

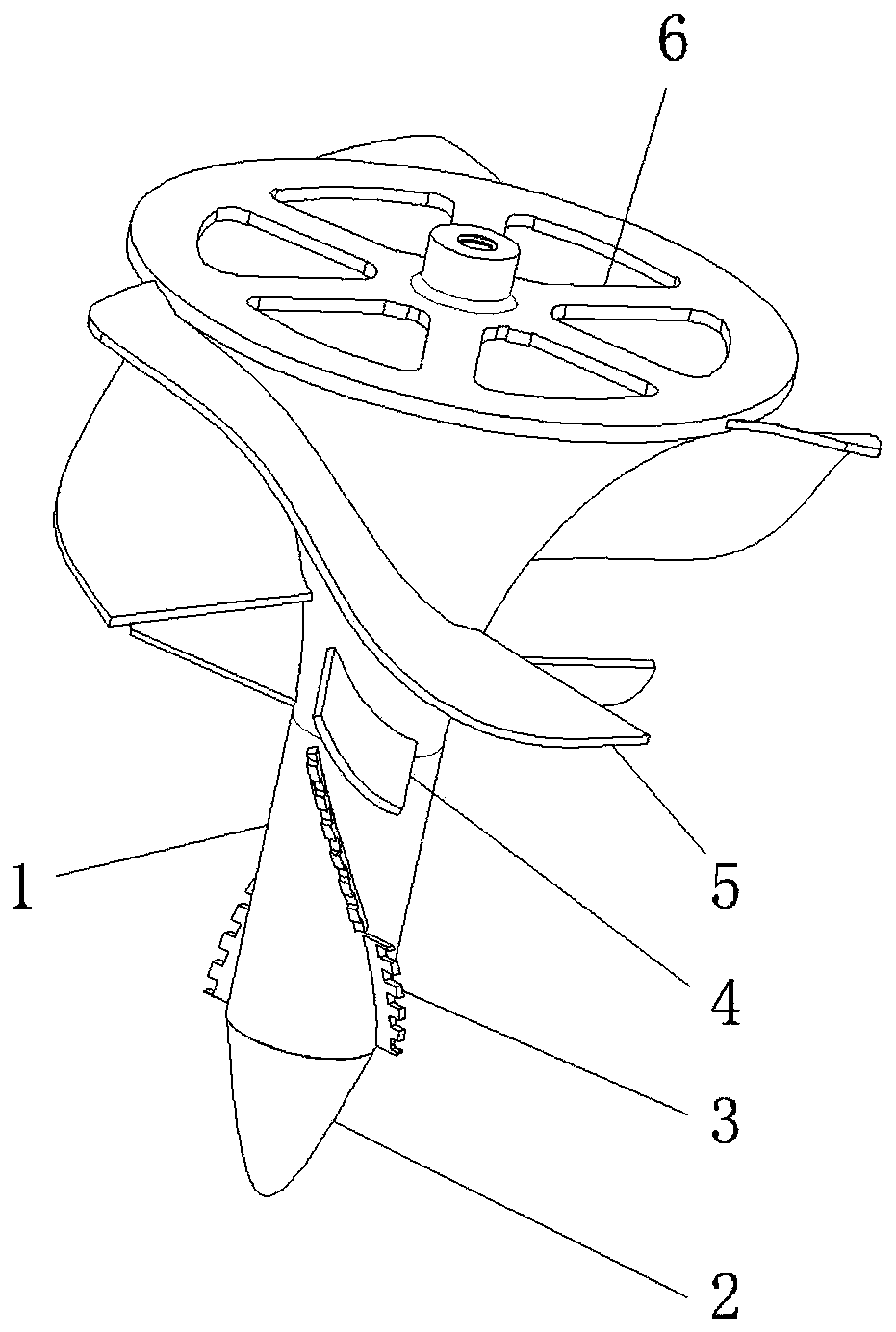

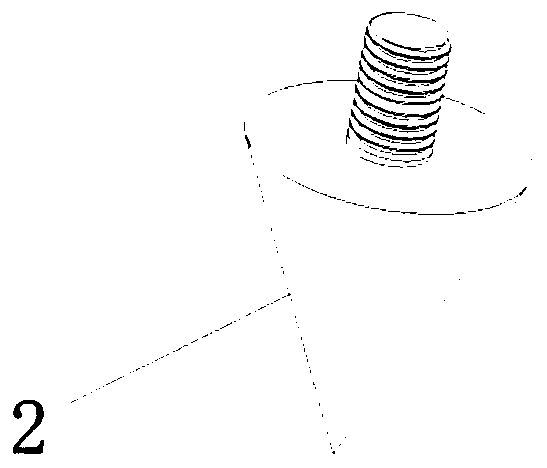

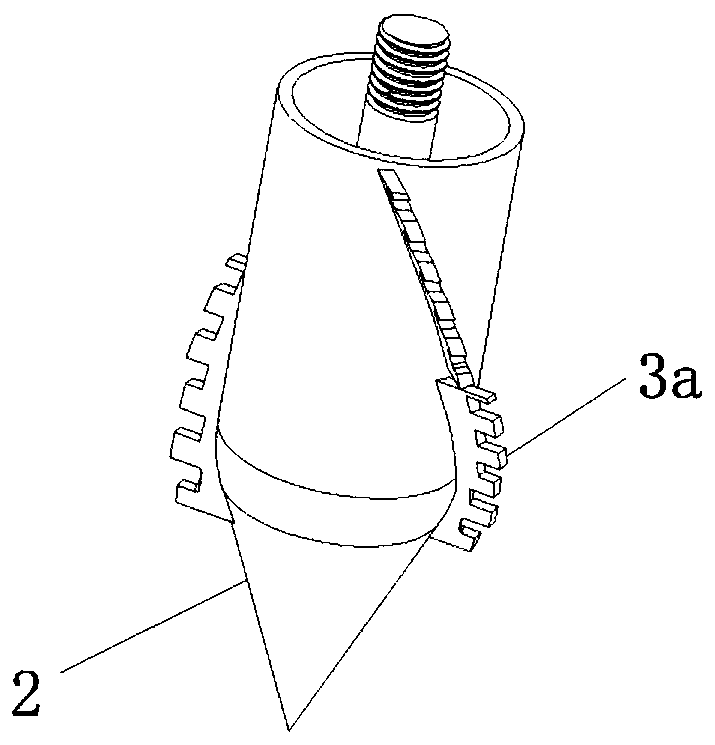

[0026] figure 1 It is a schematic diagram of the three-dimensional structure of the drill bit assembly; figure 2 Indicates the structure of the drill bit figure 1 ; image 3 Indicates the structure of the drill bit figure 2 ; Figure 4 It is a schematic diagram of the forming drilling structure;

[0027] As shown in the figure, the three-dimensional curved blade type drill bit assembly in this embodiment includes a drill bit assembly, and the drill bit assembly includes a drill rod 1 and a drill bit 2 detachably connected to the bottom of the drill rod. Small conical shape, the outer circle of the drill bit assembly is provided with at least two groups of helical blades up and down, the outer diameter of each group of said helical blades increases sequentially from bottom to top, and each group of helical blades includes a centrally symmetrical connection to the outer circle of the drill bit assembly. A plurality of helical blades; the conical structure of the drill bit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com