Comprehensive utilization method for gold tailings containing gold, iron and feldspar

A technology for gold tailings and feldspar, applied in recycling technology, solid separation, mechanical material recycling, etc., can solve the problems of low comprehensive utilization and low utilization value, and achieve improved comprehensive recycling rate, high economic and social benefits , to achieve the effect of zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail without limitation in conjunction with the accompanying drawings and examples below.

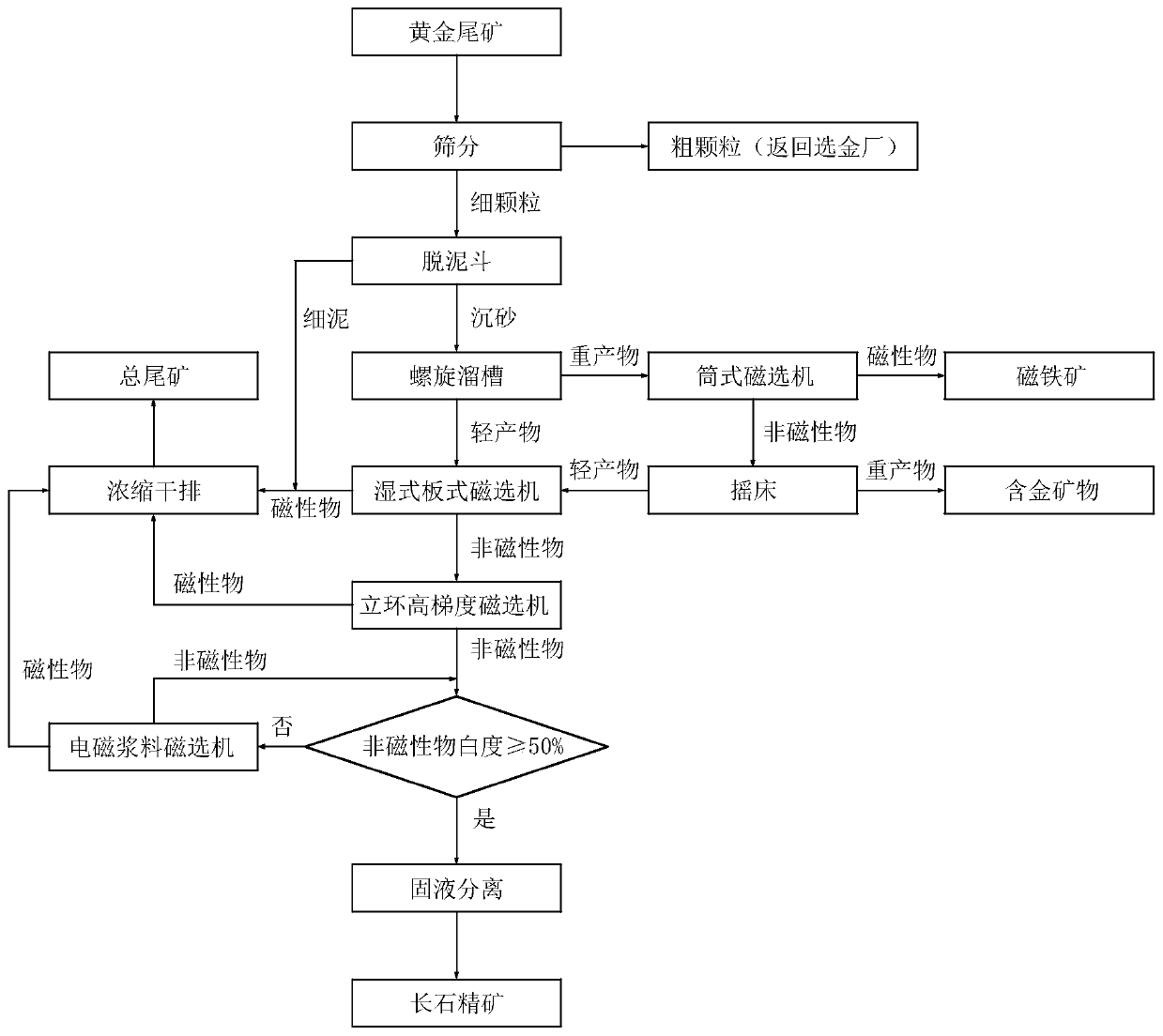

[0024] Such as figure 1 Shown, the gold tailing comprehensive utilization method containing gold, iron, feldspar of the present invention comprises the following steps:

[0025] S10 tailings classification desliming: the gold tailings are screened by screening equipment, and the screening equipment preferably adopts a high-frequency vibrating screen with a mesh number of 30 mesh; the material under the screen enters the desliming equipment to remove fine-grained mud, The desliming equipment preferably adopts a desliming bucket, which is used to remove fine-grained mud below 0.045mm; the coarse-grained sand on the screen after vibratory screening is returned to the concentrator for re-grinding and gold extraction.

[0026] S20 Separation of magnetite and gold-bearing minerals: the under-screen material after classification and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com