Novel heat-insulating and self-cleaning environmentally friendly coating

An environmentally friendly coating and self-cleaning technology, applied in the field of architectural decoration, can solve the problems of poor heat insulation performance and unsatisfactory self-cleaning performance, and achieve good acid and alkali resistance, good anti-contamination performance, and improved surface hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

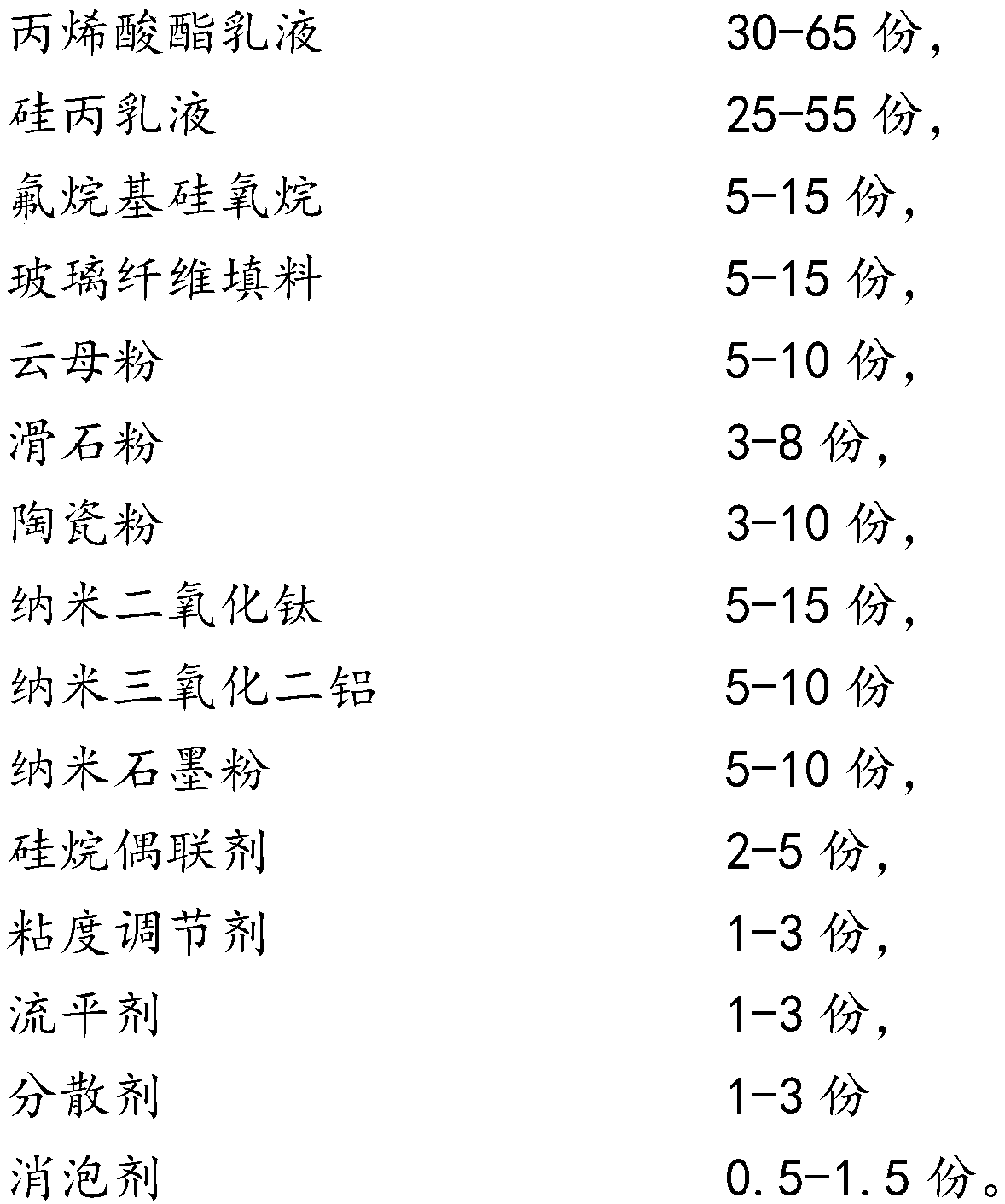

[0015] This embodiment discloses a new type of heat-insulating self-cleaning environmental protection coating, including the following raw materials measured in parts by mass:

[0016]

[0017]

Embodiment 2

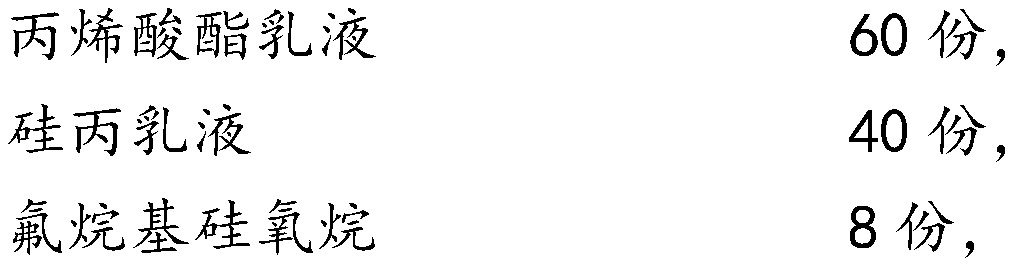

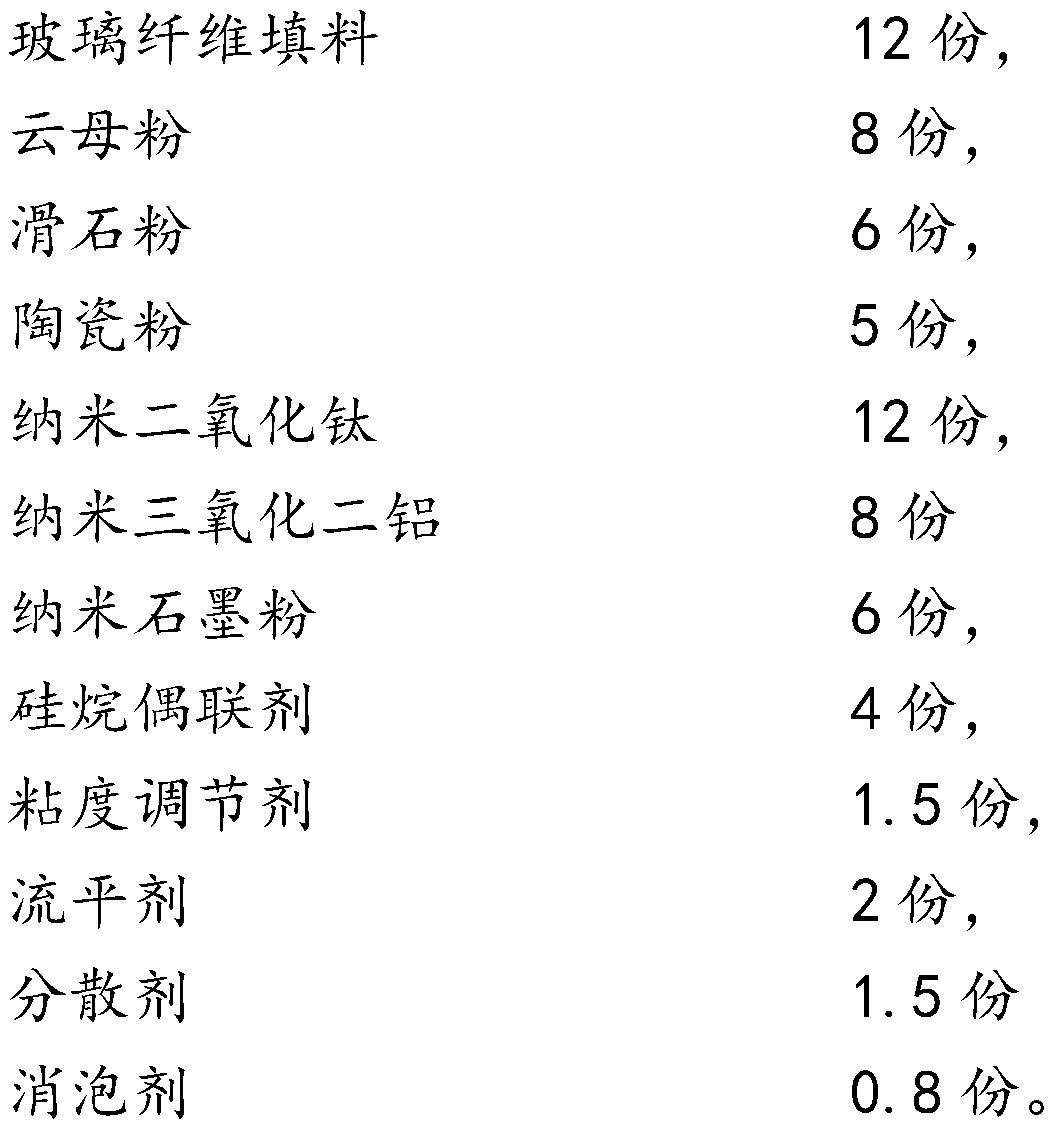

[0019] This embodiment discloses a new type of heat-insulating self-cleaning environmental protection coating, including the following raw materials measured in parts by mass:

[0020]

Embodiment 3

[0022] This embodiment discloses a new type of heat-insulating self-cleaning environmental protection coating, including the following raw materials measured in parts by mass:

[0023]

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com