Gamma-aminobutyric acid (GABA) enrichment method based on mixotrophic haematococcus pluvialis

A technology of Haematococcus pluvialis and GABA, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as high cost, food safety problems, low content and yield, and achieve Simple operation, shorten the growth cycle, and improve the effect of biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Step 1, preparation of induced algae liquid: at a temperature of 24-26°C and a light of 2800-3500lx, the basic BBM medium with 1.5-2.5g / L sodium acetate as a carbon source is also used to culture Haematococcus pluvialis, and wait for the rain Haematococcus grows to the late logarithmic phase to collect the algal cells, dilute and resuspend the algal cells with fresh BBM medium as the induced algal liquid, and the concentration of the algal liquid is 0.1-0.5g / L;

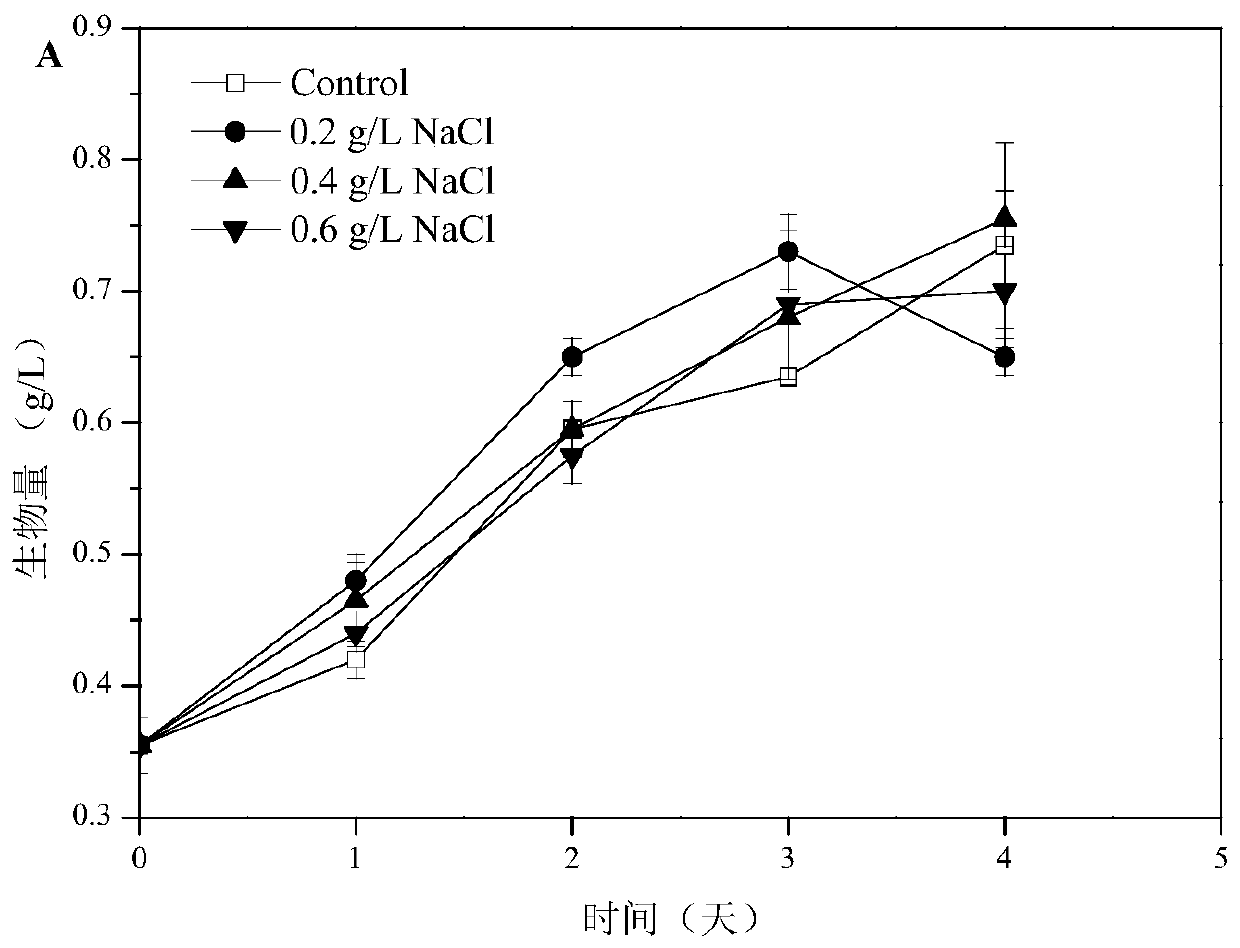

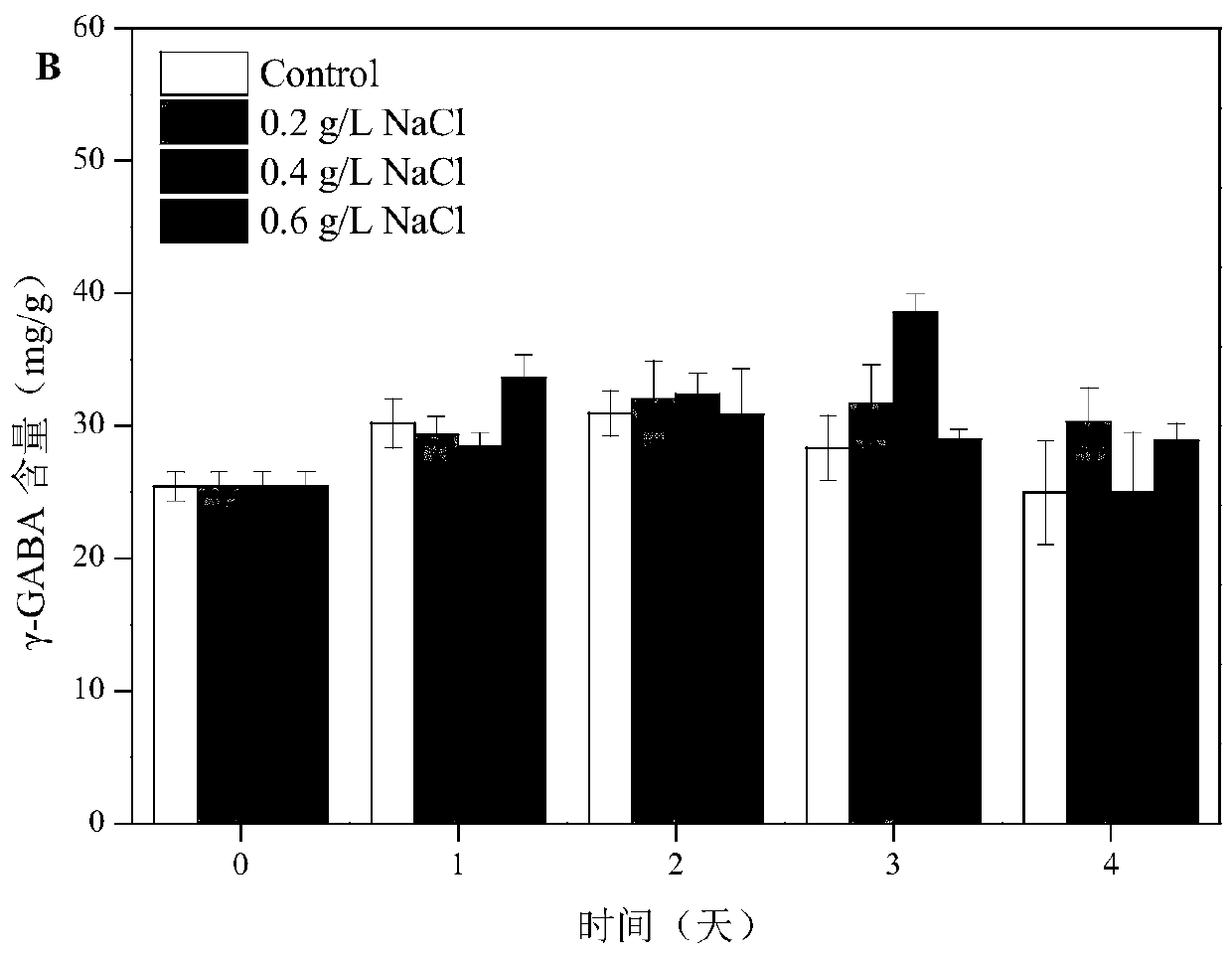

[0028] Step 2. Induce algal cells to accumulate γ-GABA: prepare 1g / L NaCl mother liquor with pure water, add appropriate amount of NaCl mother liquor to the induced algae liquor so that the NaCl concentration is 0.2-0.6g / L, and place it at 26°C-28 ℃, light intensity 12000-14000lx, cold light continuous light induction;

[0029]Step 3. Collect the algae cells the next day and detect the γ-GABA content: collect the algae liquid the next day, first enrich the algae liquid by centrifugation at 3500r / min for 10 minu...

Embodiment 1

[0031] This embodiment is based on the method for producing gamma-aminobutyric acid from Haematococcus pluvialis, the main steps of which are:

[0032] (1) When the temperature is 24°C and the light is 2800lx, the basic BBM medium with 1.5g / L sodium acetate as the carbon source is also cultured for Haematococcus pluvialis, and collected after the growth of Haematococcus pluvialis to the late logarithmic growth phase For algae cells, dilute and resuspend the algae cells with fresh BBM medium as the induced algae liquid, and the concentration of the algae liquid is 0.1g / L.

[0033] (2) Prepare 1g / L NaCl mother liquor with pure water, add an appropriate amount of NaCl mother liquor to the induced algae liquor to make the NaCl concentration 0.2g / L, and place it at 26°C under a light intensity of 12000 lx for induction culture;

[0034] (3) The algae cells were collected by centrifugation the next day, and the γ-GABA in the algae cells was extracted by using an organic solvent, and...

Embodiment 2

[0037] This embodiment is based on the method for producing gamma-aminobutyric acid from Haematococcus pluvialis, the main steps of which are:

[0038] (1) When the temperature is 25°C and the light is 3000lx, the basic BBM medium with 2g / L sodium acetate as the carbon source is used to culture Haematococcus pluvialis, and the algae are collected after the growth of Haematococcus pluvialis to the late logarithmic growth phase. Cells, dilute and resuspend algae cells with fresh BBM medium as the induced algae liquid, the concentration of the algae liquid is 0.3g / L.

[0039] (2) Prepare 1g / L NaCl mother liquor with pure water, add an appropriate amount of NaCl mother liquor to the induced algae liquor to make the NaCl concentration 0.4g / L, and place it at 27°C with a light intensity of 13000lx for induction culture;

[0040] (3) collect algae cells by centrifugation the next day, utilize organic solvent to extract gamma-GABA in the algae cells, and utilize liquid chromatography ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com