Wide dyed flannelette processing method

A processing method and wide-width dyeing technology, which is applied in the field of home textiles, can solve the problems of long air supply path, different fiber arrangement, and aggravated color difference between edges, etc., to achieve high quality and uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Specification: 105” / JC100s / 2*C40s / 200*(50+50), the weave is 4 / 1 satin, in which the warp yarn is 100s / 2 combed and compact spun cotton, and the weft is 40s carded and compact spun cotton.

[0028] The weaving process includes the following steps: warping → warp yarn sizing → browning → reed → warp stopper → weft twist fixing → weft insertion weaving.

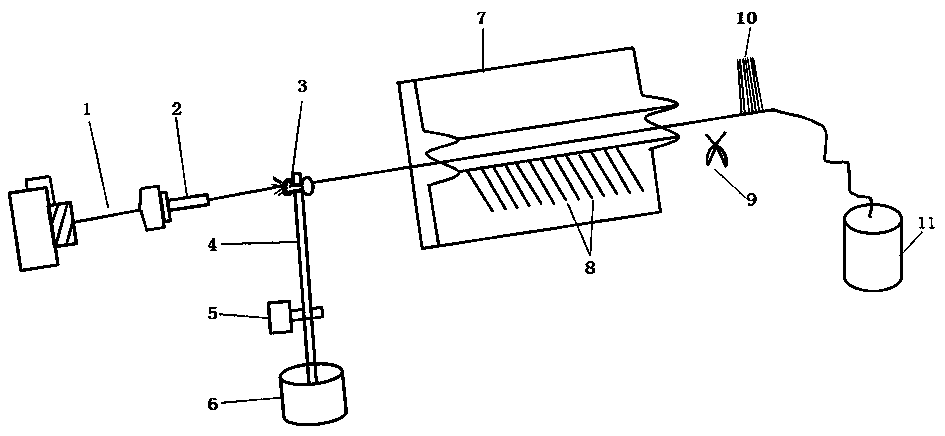

[0029] The weft twist fixing device includes 2 nozzles, a slurry tank, a connecting pipe and an electronic injection control system. The installation position of the nozzle is above or on the side between the main nozzle and the reed, and the nozzle is connected to the slurry tank through the connecting tube. Electronic injection control system. The nozzle hole is circular in shape. When weaving, the weft yarn first passes through the nozzle and then enters the shed under the action of the airflow of the main nozzle. Under the action of the electronic spraying control system, the spray head directional sprays the slurry...

Embodiment 2

[0033] Specification: 106.5” / 32s (viscose / polyester 80 / 20)*32s (viscose / polyester 80 / 20) / 133*72, the weave is 3 / 1 twill, and the warp and weft are both viscose / polyester blended Siro compact spinning 32s.

[0034] The weaving process includes the following steps: warping → warp yarn sizing → browning → reed → warp stopper → weft twist fixing → weft insertion weaving.

[0035] The weft twist fixing device includes a nozzle, a size tank, a connecting pipe and an electronic injection control system. The installation position of the nozzle is on the side between the main nozzle and the reed. system. The nozzle hole is circular in shape. When weaving, the weft yarn first passes through the nozzle and then enters the shed under the action of the airflow of the main nozzle. Under the action of the electronic injection control system, the spray head sprays the slurry at the 30mm of the head end of each weft yarn.

[0036] The dyeing and finishing process of the fabric is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com