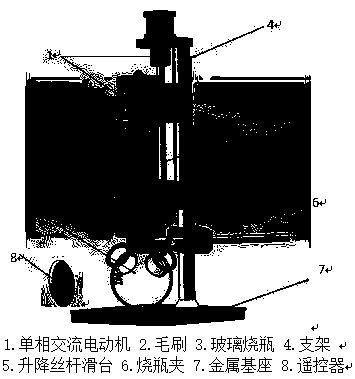

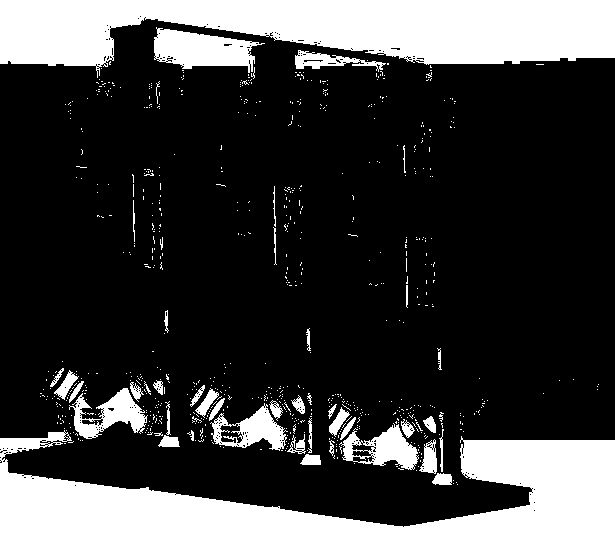

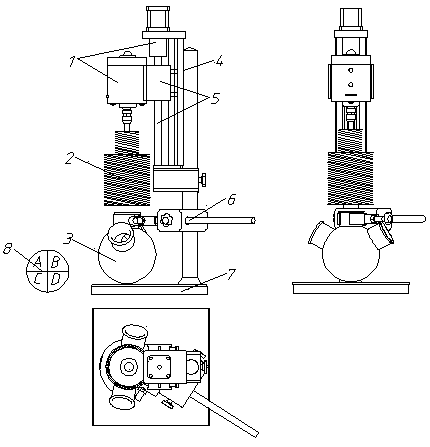

Automatic cleaning instrument for remote control type glass flask

An automatic cleaning and remote-control technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cleaning the inner wall of glass flasks, frequent use of glass flasks, and pollution of the environment by harmful waste liquids, etc. Problems, to achieve the effect of easy to use in a wide range, easy to maintain and disassemble, convenient and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Place the cleaning instrument assembled according to the requirements in the special instrument cleaning pool in the laboratory, and place the governor at a suitable position on the test bench next to the pool (note that the place where the lifting screw slide controller is placed should be waterproof ), adjust the button of the slide controller to make the screw descend at a lower speed; connect the control motor of the screw slide and the brush rotation control motor to the controller, turn on the power, and adjust the speed of the control motor of the screw slide to Maximum, the brush rotation control motor speed is in the middle range; adjust the lifting screw slide table and the motor equipped on it to a suitable height, and fix it in an appropriate position; insert the prepared brush that meets the requirements into the socket below the motor , and tighten the fastening screw to fix it; according to the position of the brush, fix the glass flask in the flask clamp....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com