Cathode system and method for nesting material electrolytic machining in low temperature environment

A low-temperature environment, cathode technology, used in machining electrodes, electric machining equipment, electrochemical machining equipment, etc., to achieve uniform corrosion, improved workpiece taper, and stray corrosion inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

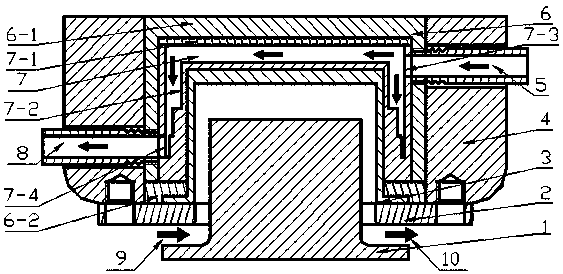

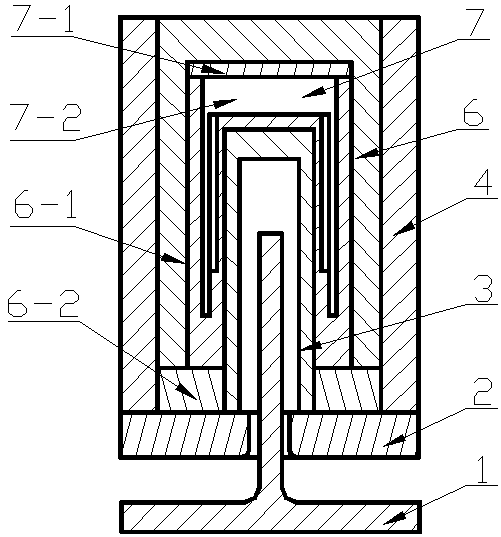

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0021] Such as figure 1 , figure 2 and image 3 As shown, a cathode system for electrolytic processing of materials in a low-temperature environment of the present invention is implemented, and it is characterized in that it includes a cathode sheet 2, an insulating sleeve 3, a cathode body 4, a refrigerant inlet pipe 5, an insulating sleeve 6, and an insulating cylinder 6-1 , heat insulation ring plate 6-2, refrigerant chamber cover 7, refrigerant chamber cover plate 7-1, refrigerant storage tank 7-2, refrigerant inlet 7-3, refrigerant outlet 7-4 and refrigerant outlet Tube 8; Electrolyte inlet 9; Electrolyte outlet 10;

[0022] The cathode body 4 is processed with a through cavity in the middle of the interior, there are holes on the left and right sides respectively communicating with the middle cavity, and there are threaded holes at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com