Nesting electrolytic machining fixture and method for blade trailing edge insoluble diffuser

A diffuser and trailing edge technology, which is applied in the field of electrolytic machining of aeroengine diffuser casing materials and electrolytic machining, can solve the problem that the processed area cannot effectively reduce stray corrosion in the processed area, unfavorable processing stability and processing accuracy, Solve problems such as stray corrosion in the processed area, achieve the effect of convenient and quick installation, simple structure, and reduce material and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with specific embodiments.

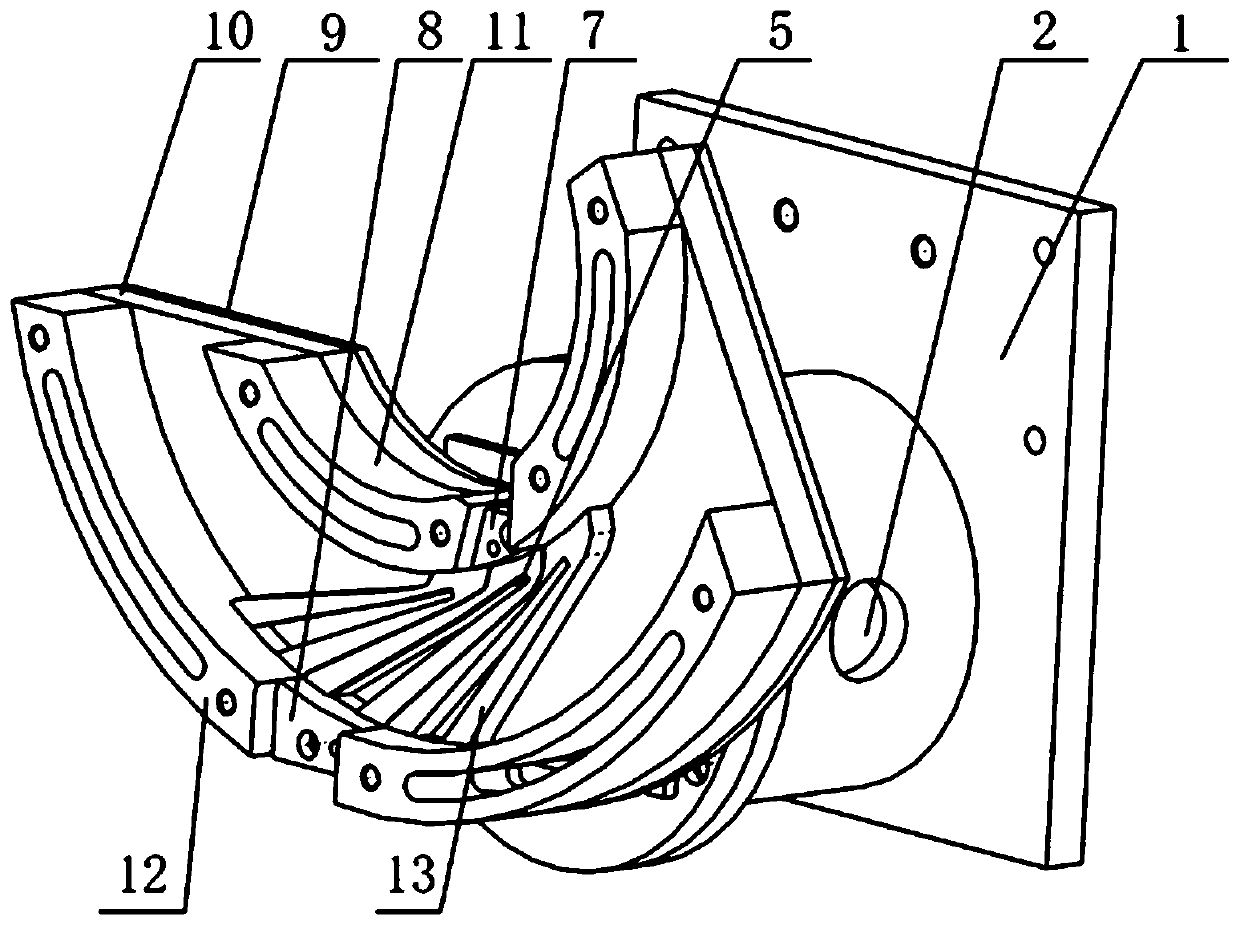

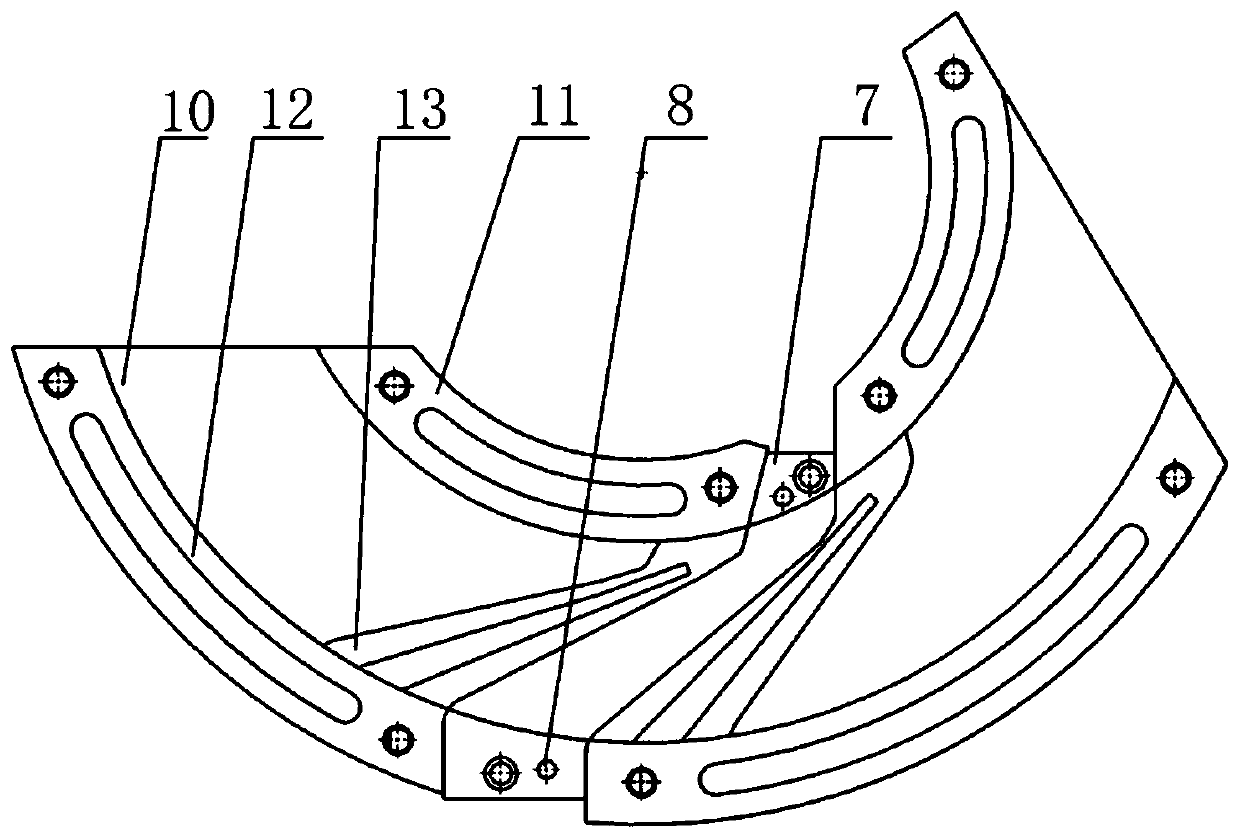

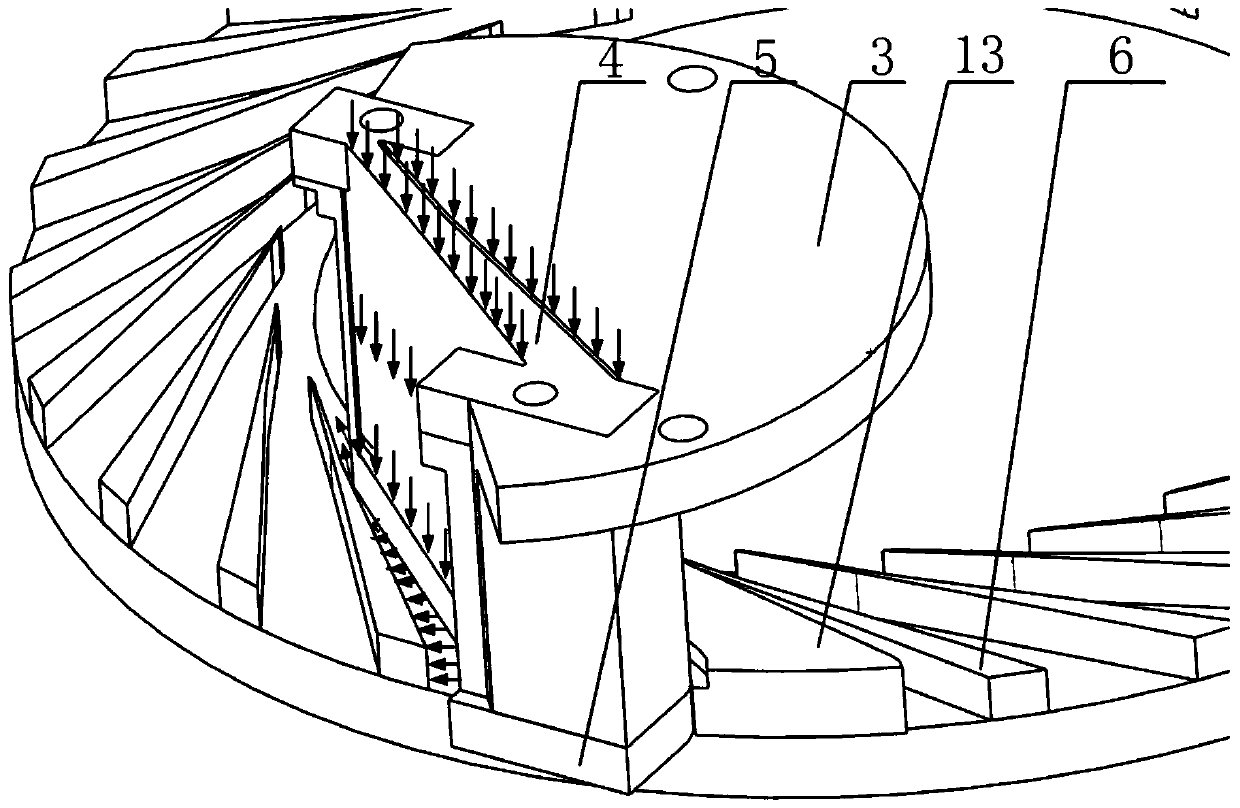

[0025] Implementation of the present invention - "a special structure diffuser sleeve electrolytic processing fixture", the device mainly includes a leading edge insulating block, a trailing edge insulating block, a supporting steel plate, a cover plate, a leading edge supporting block, and a trailing edge supporting block , Processed blade protection sleeve.

[0026] The supporting steel plate is made of stainless steel; the leading edge insulating block, the trailing edge insulating block, the cover plate, the leading edge supporting block, the trailing edge supporting block, and the processed blade protective cover are all made of epoxy resin; the supporting steel plate, the covering plate, The outer contours of the leading edge support block, the trailing edge support block, and the machined blade protective cover can be designed according to the shape of the processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com