Anti-shock and wear-resistant self-lubricating material based on polyketone, composite board and preparation method of composite board

A technology of self-lubricating materials and composite plates, which is applied in the field of wear-resistant plates, can solve problems such as high friction coefficient, limited use, and difficult to be competent, and achieve the effects of excellent performance, reduced friction coefficient, and increased use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

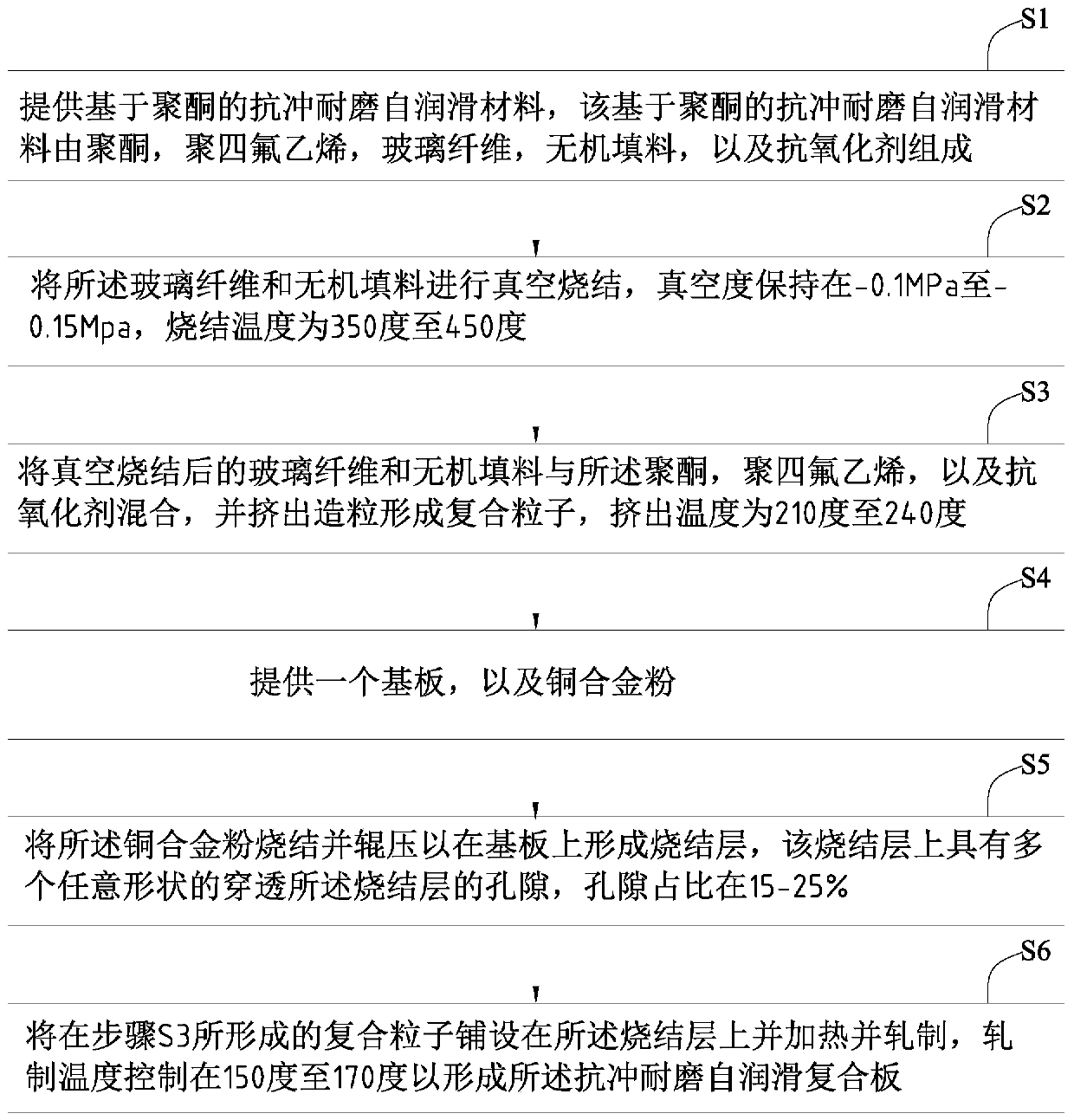

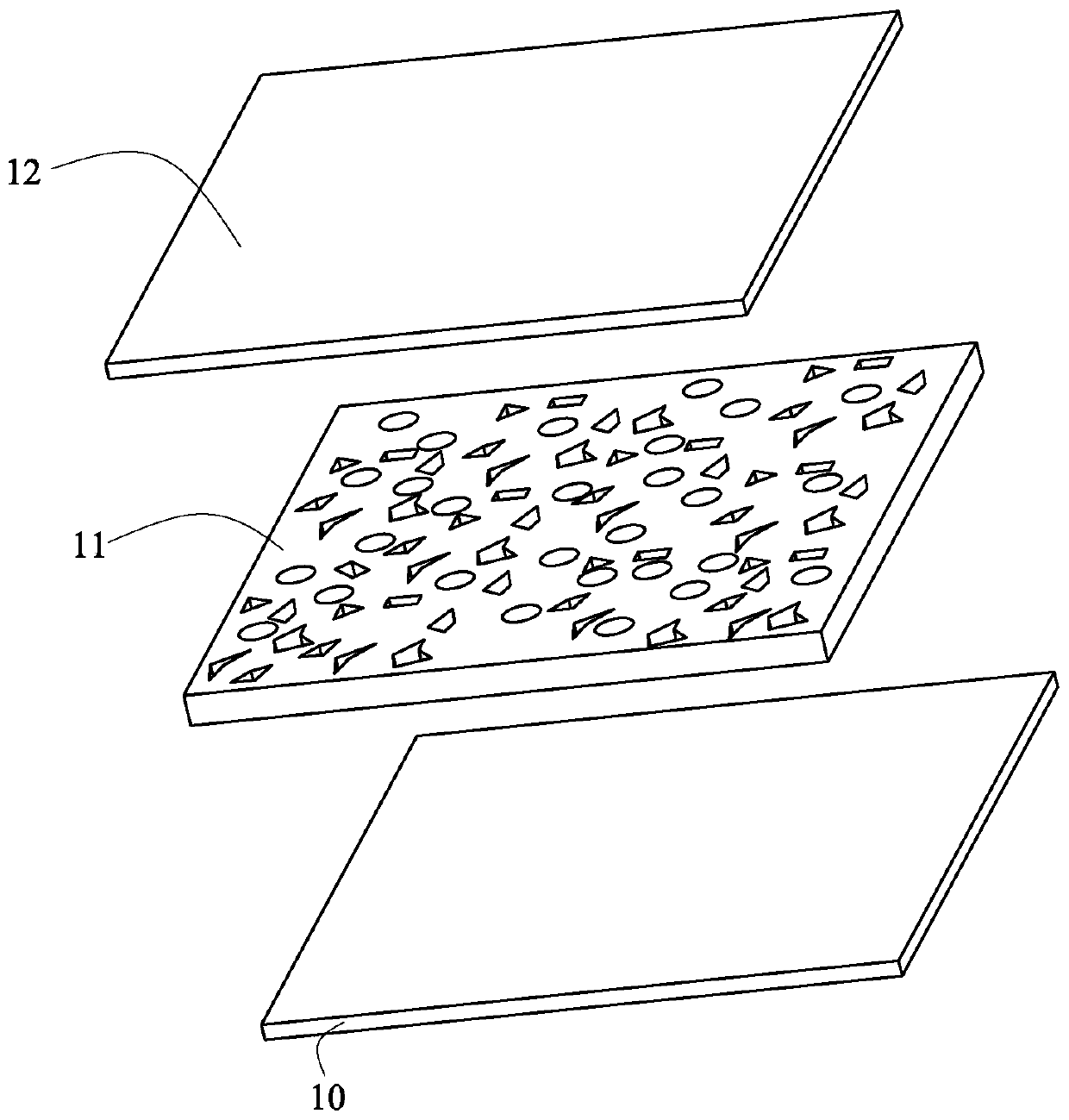

[0029] Such as figure 1 As shown, it is a flow chart of a preparation method for a composite board using a polyketone-based anti-impact wear-resistant self-lubricating material. The preparation method of described composite board comprises the steps:

[0030] S1: Provide a polyketone-based anti-impact and wear-resistant self-lubricating material, which is composed of polyketone, anhydride-grafted modified polyethylene, glass fiber, inorganic filler, lubricant and antioxidant composition;

[0031] S2: Vacuum sintering the glass fibers and inorganic fillers, the vacuum degree is maintained at -0.1MPa to -0.15Mpa, and the sintering temperature is 350 to 450 degrees;

[0032] S3: Mix the glass fiber and inorganic filler after vacuum sintering with the polyketone, anhydride graft modified polyethylene, lubricant and antioxidant, and extrude and granulate to form composite particles. The extrusion temperature is 210 to 240 Spend.

[0033] S4: provide a substrate, and copper allo...

specific Embodiment

[0038] Table 1 embodiment data table

[0039]

Embodiment 1

[0041] Step 1: Weigh 58.5 parts of polyketone, 12 parts of polyethylene with maleic anhydride graft ratio of 3%, 18 parts of sintered glass fiber, 10 parts of barium sulfate, and 1.5 parts of polytetrafluoroethylene.

[0042] Step 2: Add all the above-mentioned raw materials into a high-speed mixer with a rotation speed of 350 rpm and mix for 20 minutes to obtain a mixture.

[0043] Step 3: Extrude and granulate the above mixture through a twin-screw extruder at an extrusion temperature of 230°C.

[0044] Step 4: Lay the obtained particles on the surface of the plate for melting and sintering, and perform composite processing by hot rolling to obtain a three-layer composite plate with good wear resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com