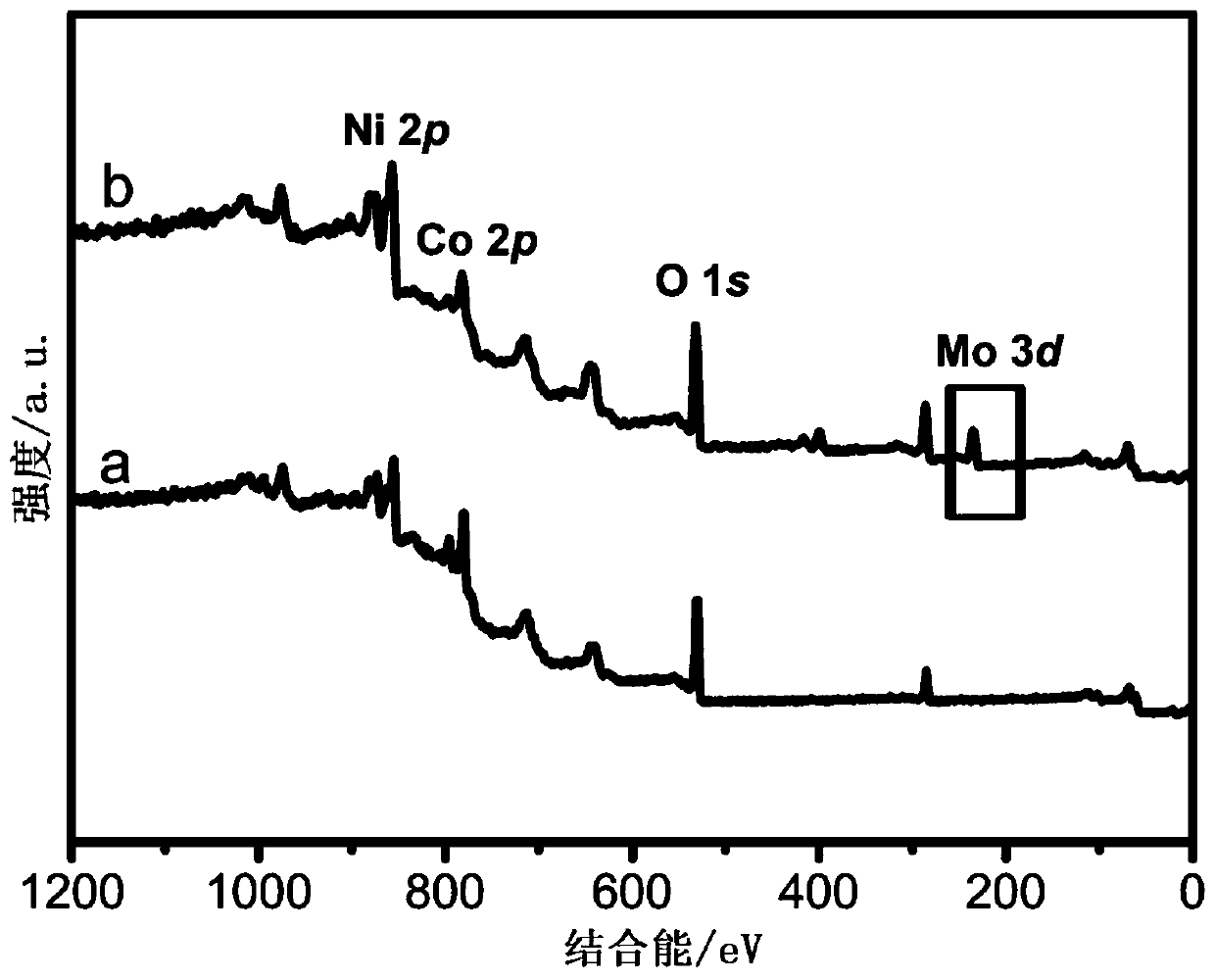

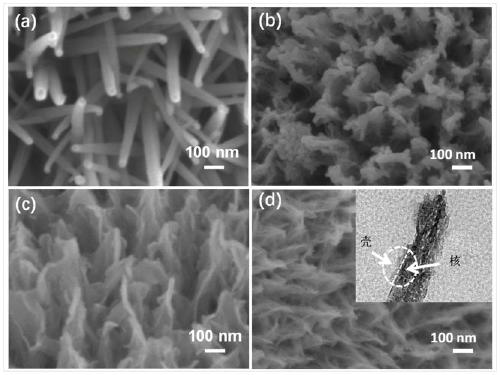

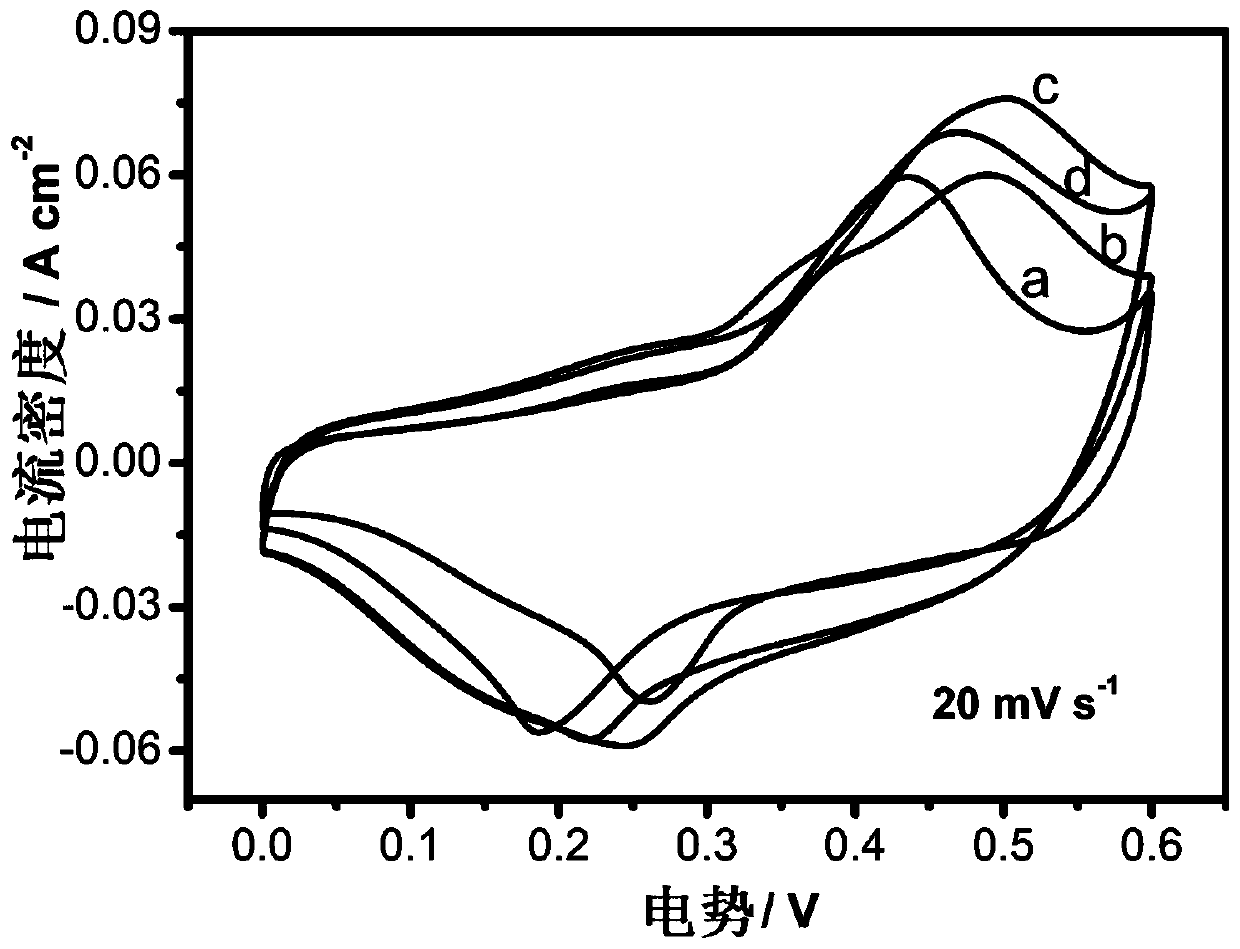

NiCo2O4@NiMoO4 core-shell structure and preparation method thereof

A core-shell structure and shell technology is applied in the field of NiCo2O4@NiMoO4 core-shell structure and its preparation, which can solve the problems of lack of and affecting the electrochemical performance of core-shell structure materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] On the one hand, the embodiment of the present invention provides a kind of NiCo 2 o 4 @NiMoO 4 A method for preparing a core-shell structure, comprising the steps of:

[0048] Step 1): NiCo growth on the current collector 2 o 4After the precursor nanostructure, the NiCo on the current collector 2 o 4 Precursor converted to NiCo 2 o 4 , to get NiCo 2 o 4 / Collector.

[0049] Specifically, the step 1) includes the following steps:

[0050] Step 11): transfer the current collector and the hydrothermal reaction solution into the hydrothermal reaction device, perform hydrothermal reaction, and grow NiCo on the current collector 2 o 4 Precursor nanowire structure, resulting in NiCo 2 o 4 Precursor / Current Collector.

[0051] Preferably, step 11) is specifically: preparing Ni(NO 3 ) 2 , Co(NO 3 ) 2 and the mixed solution of urea, stir evenly, transfer the mixed solution to the high-pressure reactor, put it vertically into the cleaned carbon cloth (the curr...

Embodiment 1

[0074] Step 1) hydrothermal reaction solution (the composition of this hydrothermal reaction solution is: 0.5mmol Ni(NO 3 ) 2 +1mmol Co(NO 3 ) 2 +2.5mmol urea+10mL deionized water) was poured into the autoclave, and the carbon cloth was soaked in the hydrothermal reaction solution. After the reaction kettle is sealed, it is placed in an oven for hydrothermal reaction. The temperature of the hydrothermal reaction is 160 ° C, and the time of the hydrothermal reaction is 4 hours. The nanowire-like NiCo grown on the surface of the carbon cloth is obtained. 2 o 4 Precursors (i.e., NiCo 2 o 4 precursor / carbon cloth). NiCo with deionized water and ethanol 2 o 4 After the precursor / carbon cloth was washed three times, it was dried in an oven at 60 °C for 24 hours. The dried NiCo 2 o 4 The precursor / carbon cloth was placed in a tube furnace and heat-treated under the protection of argon at a temperature of 300 °C for 2 hours to make nanowire-like NiCo 2 o 4 Precursor trans...

Embodiment 2

[0079] Step 1) hydrothermal reaction solution (the composition of this hydrothermal reaction solution is: 1mmol Ni(NO 3 ) 2 +2 mmol Co(NO 3 ) 2 +10mmol urea+20mL deionized water) was poured into the autoclave, and the carbon cloth was soaked in the hydrothermal reaction solution. After the reaction kettle is sealed, it is placed in an oven for hydrothermal reaction. The temperature of the hydrothermal reaction is 140 ° C, and the time of the hydrothermal reaction is 8 hours. The nanowire-shaped NiCo grown on the surface of the carbon cloth is obtained. 2 o 4 Precursors (i.e., NiCo 2 o 4 precursor / carbon cloth). NiCo with deionized water and ethanol 2 o 4 After the precursor / carbon cloth was washed three times, it was dried in an oven at a drying temperature of 80 °C for 12 hours. The dried NiCo 2 o 4 The precursor / carbon cloth was placed in a tube furnace and heat-treated under the protection of argon at a temperature of 400 °C for 1 hour to make nanowire-like NiCo ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com