A method for separating nitrate radicals in a high-concentration nickel sulfate solution

A sulfuric acid solution, nitrate technology, applied in nickel sulfate, nitric acid, chemical instruments and methods, etc., can solve problems such as nitrate separation, and achieve the effect of increasing content, high removal depth, and ensuring purity and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

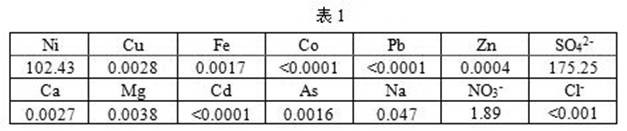

[0024] The composition (g / l) of high-concentration nickel sulfate solution is shown in Table 1:

[0025]

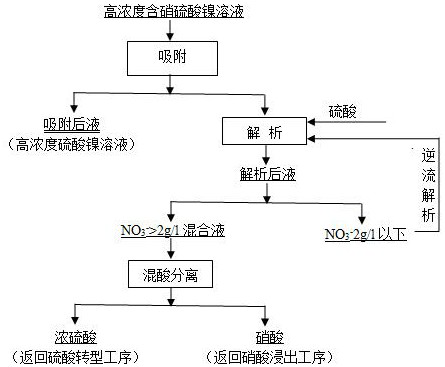

[0026] The high-concentration nickel sulfate solution separation nitrate technological process comprises the following steps:

[0027] (a) Resin adsorbs nitrate in high-concentration nickel sulfate solution: the nickel sulfate solution is adsorbed through the resin column after the last analysis, with a flow rate of 1.5BV / h; after adsorption, Ni101.5g / l in high-concentration nickel sulfate solution is obtained , NO 3 - 0.0035g / l. When the nitrate content in the adsorbed liquid is 0.098g / l, the adsorption is stopped. Wash the ion column with 1.0 BV resin volume of pure water.

[0028] (b) Sulfuric acid solution analysis: first use 10BV of sulfuric acid solution after the nitrate content of the previous production output is less than 2g / l with a concentration of 15% (mass concentration) for analysis, and then use 15% new sulfuric acid 5BV for analysis to analyze the ...

Embodiment 2

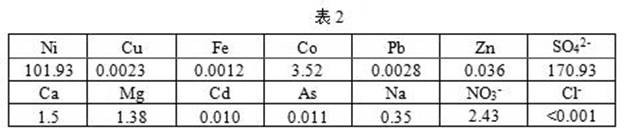

[0031] The composition (g / l) of high-concentration nickel sulfate solution is shown in Table 2:

[0032]

[0033] The high-concentration nickel sulfate solution separation nitrate technological process comprises the following steps:

[0034] a) Resin adsorption of nitrate in the high-concentration nickel sulfate solution: the nickel sulfate solution is adsorbed by the resin column after the last analysis, and the flow rate is 2.0BV / h; Ni99.35g / l, Ni99.35g / l, NO 3 - 0.004g / l. When the nitrate content in the adsorbed liquid is 0.10g / l, the adsorption is stopped. Wash the ion column with 1.0 BV resin volume of pure water.

[0035] b) Sulfuric acid solution analysis: first use 7BV of the sulfuric acid solution with a nitrate content of less than 2g / l and a concentration of 20% from the previous production for analysis, and then use 5BV of 20% new sulfuric acid for analysis, and the total acid content of the analysis is 12BV; The nitrate content in the after liquor was redu...

Embodiment 3

[0038] The composition (g / l) of the high-concentration nickel sulfate solution is shown in Table 3.

[0039]

[0040] The high-concentration nickel sulfate solution separation nitrate technological process comprises the following steps:

[0041]a) Resin adsorption of nitrate in the high-concentration nickel sulfate solution: the nickel sulfate solution is adsorbed by the resin column after the last analysis, and the flow rate is 2.2BV / h; Ni90.43g / l, Ni90.43g / l, NO 3 - 0.0022g / l. When the nitrate content in the adsorbed liquid is 0.089g / l, the adsorption is stopped. Wash the ion column with 1.0 BV resin volume of pure water.

[0042] b) Sulfuric acid solution analysis: first use 5BV of sulfuric acid solution with nitrate content less than 2g / l and concentration of 20% from the previous production for analysis, and then analyze with 6BV of 20% new sulfuric acid, and analyze the total acid content of 11BV; The nitrate content in the after liquor was reduced from 14.63g / l ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com