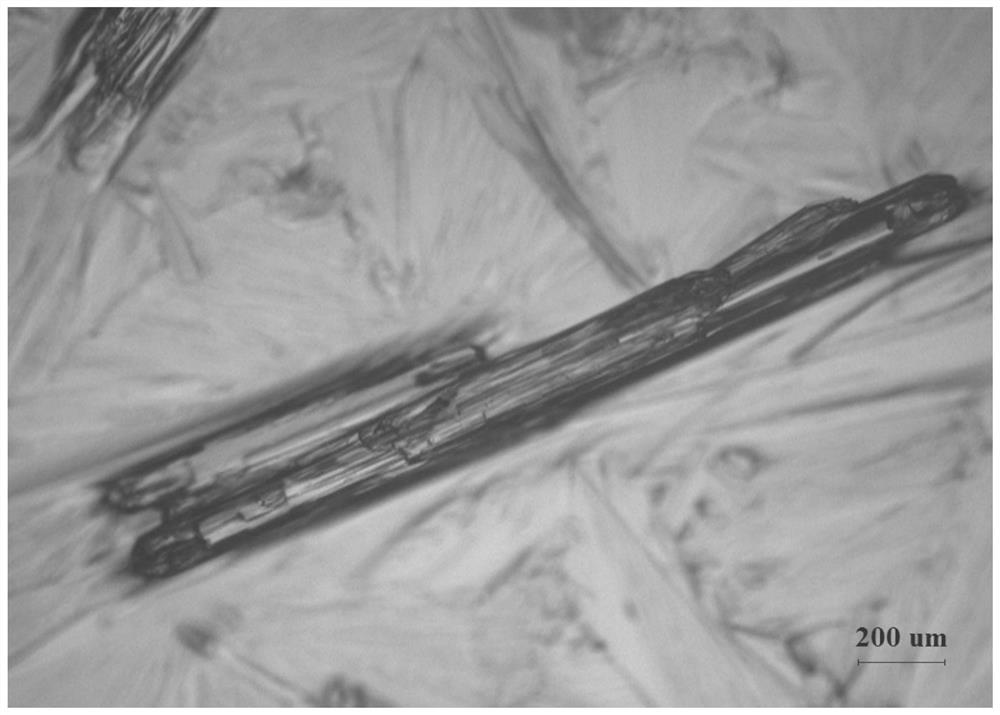

A kind of n,2,3-trimethyl-2-isopropylbutanamide crystal with short rod shape and its crystallization process

A technology of isopropyl butyramide and trimethyl, which is applied in the field of N,2,3-trimethyl-2-isopropylbutyramide crystal and its crystallization process, can solve the problems of easy agglomeration, filtration and storage. And problems such as inconvenience in the transportation process, to achieve the effect of good crystal morphology reproducibility, improved filtration efficiency, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A crystallization process of N,2,3-trimethyl-2-isopropylbutanamide, comprising the steps of:

[0052] 1) Add 400g of commercially available WS-23 and 500g of n-hexane into a 2L jacketed crystallization kettle, set the temperature of the water bath at 25°C, and completely dissolve WS-23 under the stirring condition of 300rpm to obtain solution A;

[0053]2) Cool solution A to 21 °C at a cooling rate of 3 °C / h. At this time, the solution is still clear, indicating that WS-23 is still in a complete solution state. Add 4 g of WS-23 seed crystals (WS -23), stir at 21°C at a constant temperature of 300rpm for 0.5h for the first crystallization, maintain the stirring speed and continue to cool down to 0°C at a cooling rate of 3°C / h for the second crystallization, after the crystallization is completed, quickly use Suction filtration and washing with a pre-cooled Buchner funnel, and drying in a vacuum oven at 30°C for 12 hours to obtain N,2,3-trimethyl-2-isopropylbutanamide wit...

Embodiment 2

[0056] A crystallization process of N,2,3-trimethyl-2-isopropylbutanamide, comprising the steps of:

[0057] 1) Add 100g of commercially available WS-23 and 500g of n-hexane into a 2L jacketed crystallization kettle, set the temperature of the water bath at 30°C, and completely dissolve WS-23 under the stirring condition of 400rpm to obtain solution A;

[0058] 2) Cool solution A to 21 °C at a cooling rate of 12 °C / h. At this time, the solution is still clear, indicating that WS-23 is still in a complete solution state. Add 3 g of WS-23 seed crystals (WS -23), stir at 21°C at a constant temperature of 400rpm for 2 hours for the first crystallization, maintain the stirring speed and continue to cool down to -1°C at a cooling rate of 12°C / h, and perform the second crystallization. After the crystallization is completed, quickly use Suction filtration and washing with a pre-cooled Buchner funnel, and drying in a vacuum oven at 40°C for 12 hours to obtain N,2,3-trimethyl-2-isoprop...

Embodiment 3

[0060] A crystallization process of N,2,3-trimethyl-2-isopropylbutanamide, comprising the steps of:

[0061] 1) Add 350g of commercially available WS-23 and 500g of n-hexane into a 2L jacketed crystallization kettle, set the temperature of the water bath at 25°C, and completely dissolve WS-23 under the stirring condition of 400rpm to obtain solution A;

[0062] 2) Cool solution A to 21°C at a cooling rate of 6°C / h. At this time, the solution is still clear, indicating that WS-23 is still in a complete solution state. Add 14g WS-23 seed crystals (WS obtained by rapid cooling and spontaneous crystallization) -23), stir at 21°C at a constant temperature of 400rpm for 1h for the first crystallization, keep the stirring speed and continue to cool down to 0°C at a cooling rate of 6°C / h, and carry out the second crystallization. Suction filter with a cold Buchner funnel, wash, and dry in a vacuum oven at 40°C for 12 hours to obtain N,2,3-trimethyl-2-isopropylbutanamide with the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com